Are you a seasoned Raw Scales Operator seeking a new career path? Discover our professionally built Raw Scales Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

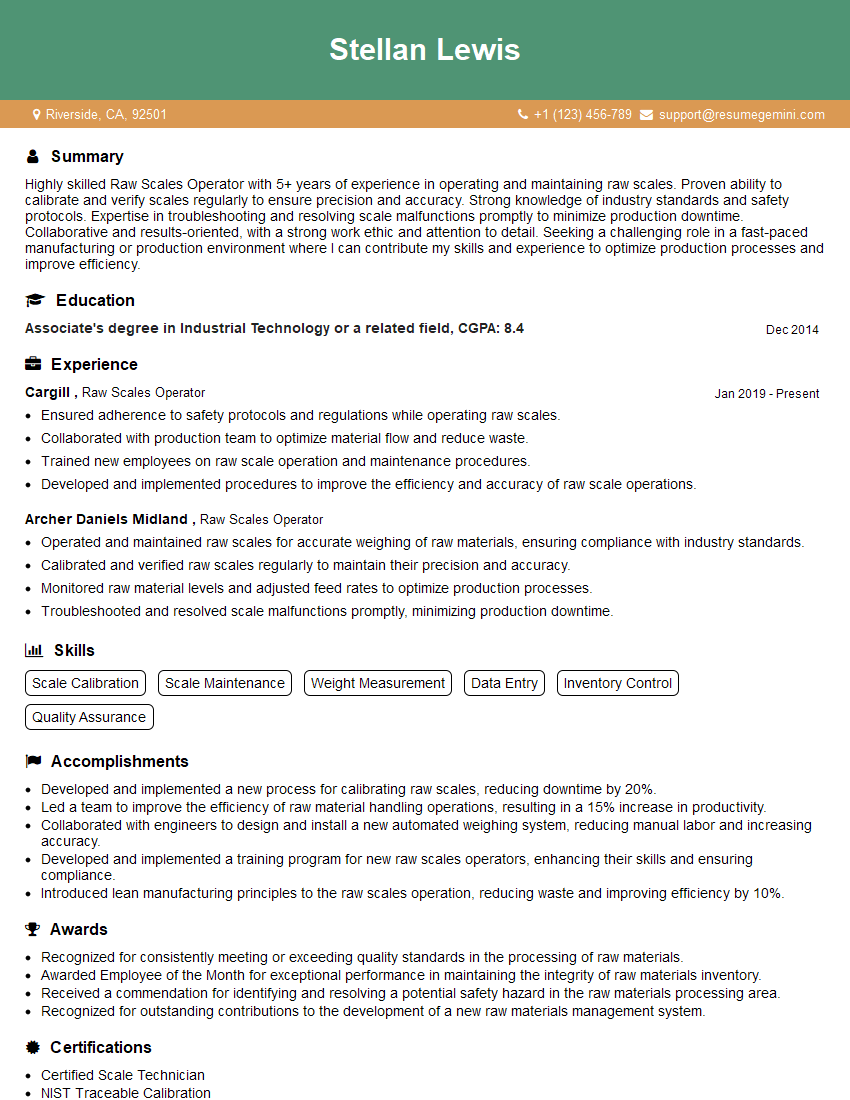

Stellan Lewis

Raw Scales Operator

Summary

Highly skilled Raw Scales Operator with 5+ years of experience in operating and maintaining raw scales. Proven ability to calibrate and verify scales regularly to ensure precision and accuracy. Strong knowledge of industry standards and safety protocols. Expertise in troubleshooting and resolving scale malfunctions promptly to minimize production downtime. Collaborative and results-oriented, with a strong work ethic and attention to detail. Seeking a challenging role in a fast-paced manufacturing or production environment where I can contribute my skills and experience to optimize production processes and improve efficiency.

Education

Associate’s degree in Industrial Technology or a related field

December 2014

Skills

- Scale Calibration

- Scale Maintenance

- Weight Measurement

- Data Entry

- Inventory Control

- Quality Assurance

Work Experience

Raw Scales Operator

- Ensured adherence to safety protocols and regulations while operating raw scales.

- Collaborated with production team to optimize material flow and reduce waste.

- Trained new employees on raw scale operation and maintenance procedures.

- Developed and implemented procedures to improve the efficiency and accuracy of raw scale operations.

Raw Scales Operator

- Operated and maintained raw scales for accurate weighing of raw materials, ensuring compliance with industry standards.

- Calibrated and verified raw scales regularly to maintain their precision and accuracy.

- Monitored raw material levels and adjusted feed rates to optimize production processes.

- Troubleshooted and resolved scale malfunctions promptly, minimizing production downtime.

Accomplishments

- Developed and implemented a new process for calibrating raw scales, reducing downtime by 20%.

- Led a team to improve the efficiency of raw material handling operations, resulting in a 15% increase in productivity.

- Collaborated with engineers to design and install a new automated weighing system, reducing manual labor and increasing accuracy.

- Developed and implemented a training program for new raw scales operators, enhancing their skills and ensuring compliance.

- Introduced lean manufacturing principles to the raw scales operation, reducing waste and improving efficiency by 10%.

Awards

- Recognized for consistently meeting or exceeding quality standards in the processing of raw materials.

- Awarded Employee of the Month for exceptional performance in maintaining the integrity of raw materials inventory.

- Received a commendation for identifying and resolving a potential safety hazard in the raw materials processing area.

- Recognized for outstanding contributions to the development of a new raw materials management system.

Certificates

- Certified Scale Technician

- NIST Traceable Calibration

- ISO 9001

- Lean Six Sigma

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Raw Scales Operator

- Highlight your experience operating and maintaining raw scales in a variety of settings.

- Showcase your ability to calibrate and verify scales to ensure accuracy and precision.

- Emphasize your knowledge of industry standards and safety protocols.

- Describe your problem-solving skills and ability to troubleshoot and resolve scale malfunctions.

- Mention your experience in training new employees and developing procedures to improve efficiency.

Essential Experience Highlights for a Strong Raw Scales Operator Resume

- Operated and maintained raw scales for accurate weighing of raw materials, ensuring compliance with industry standards.

- Calibrated and verified raw scales regularly to maintain their precision and accuracy.

- Monitored raw material levels and adjusted feed rates to optimize production processes.

- Troubleshooted and resolved scale malfunctions promptly, minimizing production downtime.

- Ensured adherence to safety protocols and regulations while operating raw scales.

- Collaborated with production team to optimize material flow and reduce waste.

- Trained new employees on raw scale operation and maintenance procedures.

Frequently Asked Questions (FAQ’s) For Raw Scales Operator

What are the primary responsibilities of a Raw Scales Operator?

Raw Scales Operators are responsible for operating and maintaining raw scales, ensuring compliance with industry standards, calibrating and verifying scales regularly, monitoring raw material levels and adjusting feed rates, and troubleshooting/resolving scale malfunctions.

What Qualifications are required to become a Raw Scales Operator?

A high school diploma or equivalent is typically required, as well as some experience in a manufacturing or production environment. Training on specific equipment and procedures is usually provided by the employer.

What are the career prospects for Raw Scales Operators?

With experience, Raw Scales Operators can advance to supervisory or management positions. They may also specialize in a particular area, such as calibration or maintenance.

What are the key skills required for Raw Scales Operators?

Key skills include the ability to operate and maintain scales, calibrate and verify scales, troubleshoot and resolve malfunctions, and adhere to safety protocols.

What are the working conditions like for Raw Scales Operators?

Raw Scales Operators typically work in a manufacturing or production environment. They may be exposed to noise, dust, and other hazards. They typically work regular hours, but may be required to work overtime on occasion.