Are you a seasoned Reamer seeking a new career path? Discover our professionally built Reamer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

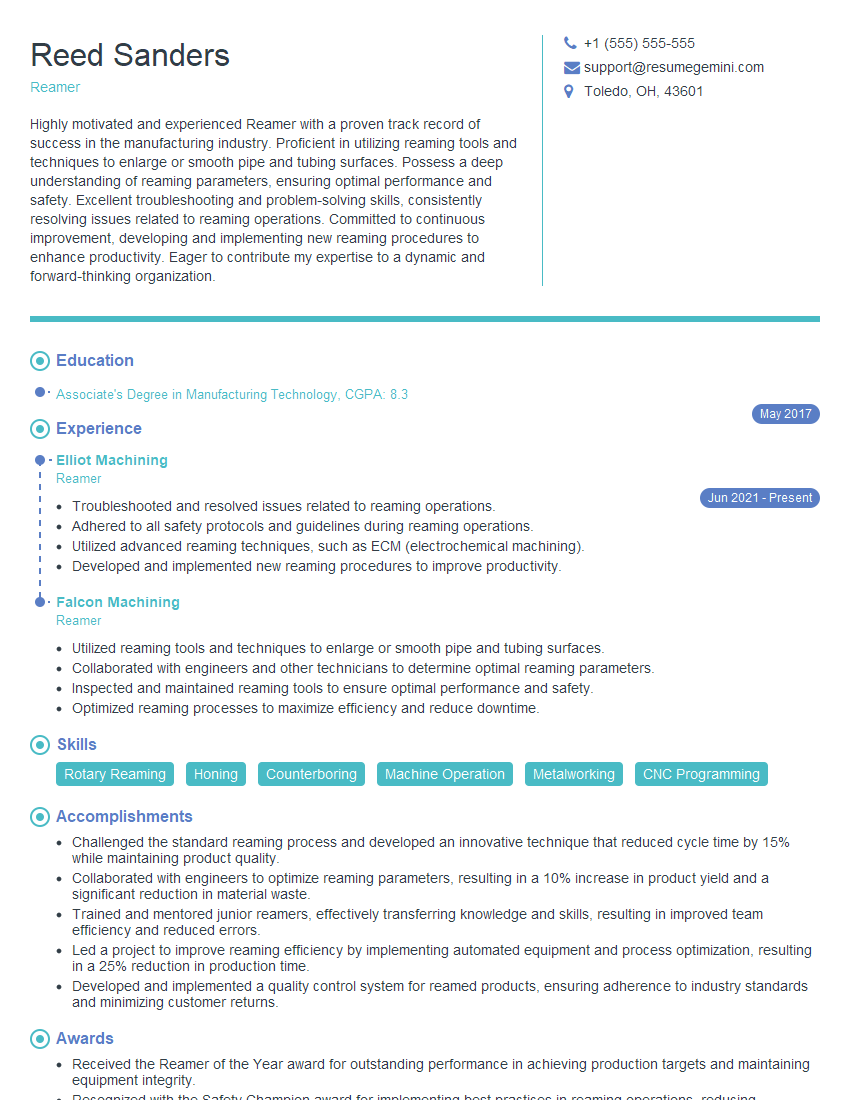

Reed Sanders

Reamer

Summary

Highly motivated and experienced Reamer with a proven track record of success in the manufacturing industry. Proficient in utilizing reaming tools and techniques to enlarge or smooth pipe and tubing surfaces. Possess a deep understanding of reaming parameters, ensuring optimal performance and safety. Excellent troubleshooting and problem-solving skills, consistently resolving issues related to reaming operations. Committed to continuous improvement, developing and implementing new reaming procedures to enhance productivity. Eager to contribute my expertise to a dynamic and forward-thinking organization.

Education

Associate’s Degree in Manufacturing Technology

May 2017

Skills

- Rotary Reaming

- Honing

- Counterboring

- Machine Operation

- Metalworking

- CNC Programming

Work Experience

Reamer

- Troubleshooted and resolved issues related to reaming operations.

- Adhered to all safety protocols and guidelines during reaming operations.

- Utilized advanced reaming techniques, such as ECM (electrochemical machining).

- Developed and implemented new reaming procedures to improve productivity.

Reamer

- Utilized reaming tools and techniques to enlarge or smooth pipe and tubing surfaces.

- Collaborated with engineers and other technicians to determine optimal reaming parameters.

- Inspected and maintained reaming tools to ensure optimal performance and safety.

- Optimized reaming processes to maximize efficiency and reduce downtime.

Accomplishments

- Challenged the standard reaming process and developed an innovative technique that reduced cycle time by 15% while maintaining product quality.

- Collaborated with engineers to optimize reaming parameters, resulting in a 10% increase in product yield and a significant reduction in material waste.

- Trained and mentored junior reamers, effectively transferring knowledge and skills, resulting in improved team efficiency and reduced errors.

- Led a project to improve reaming efficiency by implementing automated equipment and process optimization, resulting in a 25% reduction in production time.

- Developed and implemented a quality control system for reamed products, ensuring adherence to industry standards and minimizing customer returns.

Awards

- Received the Reamer of the Year award for outstanding performance in achieving production targets and maintaining equipment integrity.

- Recognized with the Safety Champion award for implementing best practices in reaming operations, reducing workplace hazards by 20%.

- Awarded the Excellence in Reaming medal for consistently exceeding production targets and contributing to the teams overall productivity.

- Received the Innovation Award for developing a new reaming tool that significantly improved hole accuracy and reduced tool wear.

Certificates

- National Institute for Metalworking Skills (NIMS)

- American Welding Society (AWS)

- Society of Manufacturing Engineers (SME)

- American Society for Quality (ASQ)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reamer

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your expertise in advanced reaming techniques and technologies.

- Demonstrate your understanding of reaming parameters and their impact on surface quality and efficiency.

- Emphasize your commitment to safety and adherence to industry standards.

Essential Experience Highlights for a Strong Reamer Resume

- Utilized reaming tools and techniques to enlarge or smooth pipe and tubing surfaces, ensuring precision and accuracy.

- Collaborated with engineers and other technicians to determine optimal reaming parameters, maximizing efficiency and minimizing downtime.

- Inspected and maintained reaming tools regularly, ensuring optimal performance and adherence to safety protocols.

- Optimized reaming processes to maximize efficiency, reduce cycle time, and enhance productivity.

- Troubleshooted and resolved issues related to reaming operations, minimizing disruptions and maintaining seamless production.

- Adhered to all safety protocols and guidelines during reaming operations, prioritizing the well-being of oneself and others.

- Utilized advanced reaming techniques, such as ECM (electrochemical machining), to achieve superior surface finishes and precise dimensions.

Frequently Asked Questions (FAQ’s) For Reamer

What are the key responsibilities of a Reamer?

Reamer responsibilities include utilizing reaming tools and techniques, collaborating with engineers, inspecting and maintaining reaming tools, optimizing reaming processes, troubleshooting issues, adhering to safety protocols, and utilizing advanced reaming techniques.

What are the essential skills for a successful Reamer?

Essential skills for a Reamer include rotary reaming, honing, counterboring, machine operation, metalworking, and CNC programming.

What industries employ Reamers?

Reamers are employed in various industries, including manufacturing, automotive, aerospace, and construction.

What are the career prospects for Reamers?

Reamers with experience and specialized skills can advance to roles such as Production Supervisor, Quality Control Manager, or Manufacturing Engineer.

What is the average salary range for Reamers?

The average salary range for Reamers varies depending on experience, location, and industry, but typically falls between $30,000 and $70,000 per year.

What are the key challenges faced by Reamers?

Key challenges faced by Reamers include ensuring precision and accuracy, maintaining tool performance, optimizing processes for efficiency, and adhering to safety protocols.

What are the latest trends in reaming technology?

Recent trends in reaming technology include the adoption of advanced techniques such as ECM (electrochemical machining) and the integration of automation and robotics.

What certifications are beneficial for Reamers?

Beneficial certifications for Reamers include the Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME) and the Certified Production Technician (CPT) from the National Institute for Metalworking Skills (NIMS).