Are you a seasoned Reaming Machine Operator seeking a new career path? Discover our professionally built Reaming Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

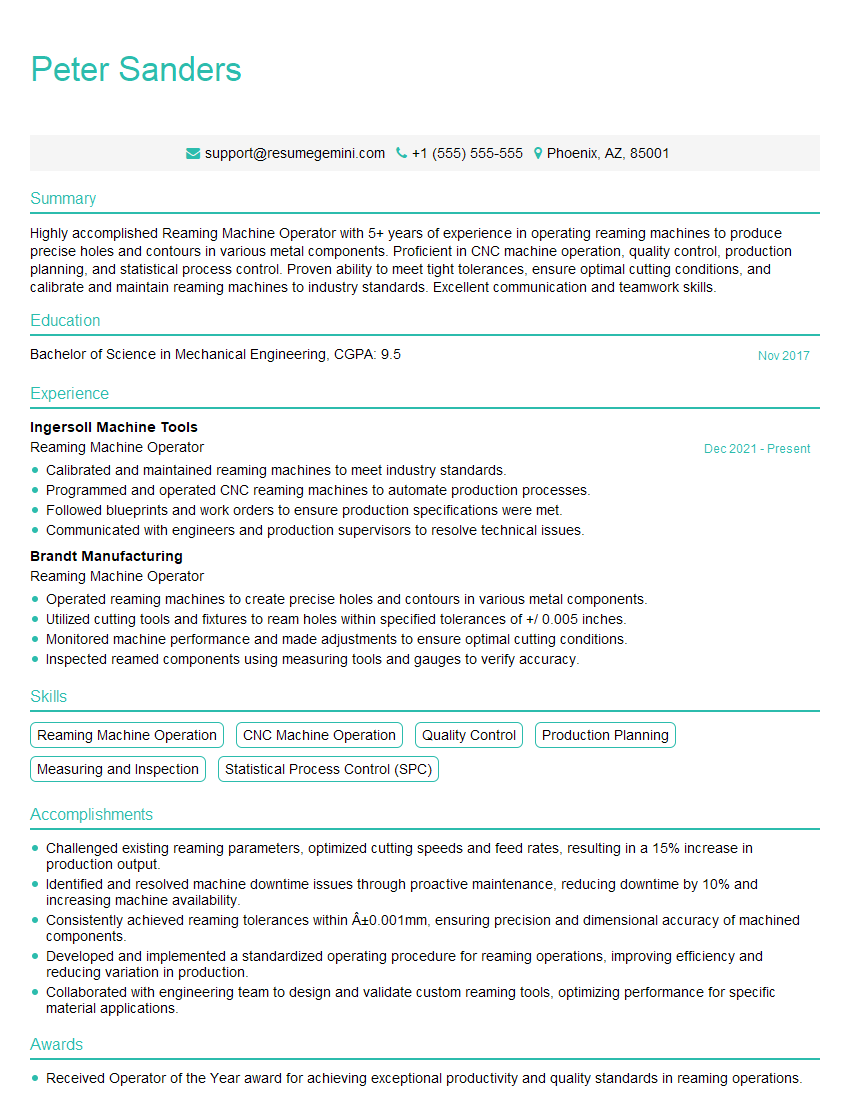

Peter Sanders

Reaming Machine Operator

Summary

Highly accomplished Reaming Machine Operator with 5+ years of experience in operating reaming machines to produce precise holes and contours in various metal components. Proficient in CNC machine operation, quality control, production planning, and statistical process control. Proven ability to meet tight tolerances, ensure optimal cutting conditions, and calibrate and maintain reaming machines to industry standards. Excellent communication and teamwork skills.

Education

Bachelor of Science in Mechanical Engineering

November 2017

Skills

- Reaming Machine Operation

- CNC Machine Operation

- Quality Control

- Production Planning

- Measuring and Inspection

- Statistical Process Control (SPC)

Work Experience

Reaming Machine Operator

- Calibrated and maintained reaming machines to meet industry standards.

- Programmed and operated CNC reaming machines to automate production processes.

- Followed blueprints and work orders to ensure production specifications were met.

- Communicated with engineers and production supervisors to resolve technical issues.

Reaming Machine Operator

- Operated reaming machines to create precise holes and contours in various metal components.

- Utilized cutting tools and fixtures to ream holes within specified tolerances of +/ 0.005 inches.

- Monitored machine performance and made adjustments to ensure optimal cutting conditions.

- Inspected reamed components using measuring tools and gauges to verify accuracy.

Accomplishments

- Challenged existing reaming parameters, optimized cutting speeds and feed rates, resulting in a 15% increase in production output.

- Identified and resolved machine downtime issues through proactive maintenance, reducing downtime by 10% and increasing machine availability.

- Consistently achieved reaming tolerances within ±0.001mm, ensuring precision and dimensional accuracy of machined components.

- Developed and implemented a standardized operating procedure for reaming operations, improving efficiency and reducing variation in production.

- Collaborated with engineering team to design and validate custom reaming tools, optimizing performance for specific material applications.

Awards

- Received Operator of the Year award for achieving exceptional productivity and quality standards in reaming operations.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- National Institute for Metalworking Skills (NIMS) Credential

- American Society for Quality (ASQ) Certified Quality Technician (CQT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reaming Machine Operator

- Highlight your experience and skills in operating reaming machines, especially if you have worked with different types of reaming machines or have experience in CNC operation.

- Quantify your accomplishments whenever possible. For example, instead of saying ‘operated reaming machines,’ you could say ‘operated reaming machines to produce components with a tolerance of +/-0.005 inches.’

- Include keywords that potential employers will be searching for, such as ‘reaming machine operator,’ ‘CNC machine operator,’ ‘quality control,’ and ‘production planning.’

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Reaming Machine Operator Resume

- Operate reaming machines to create precise holes and contours in metal components.

- Utilize cutting tools and fixtures to ream holes within specified tolerances.

- Monitor machine performance and make adjustments to ensure optimal cutting conditions.

- Inspect reamed components using measuring tools and gauges to verify accuracy.

- Calibrate and maintain reaming machines to meet industry standards.

- Program and operate CNC reaming machines to automate production processes.

- Communicate with engineers and production supervisors to resolve technical issues.

Frequently Asked Questions (FAQ’s) For Reaming Machine Operator

What is a reaming machine operator?

A reaming machine operator is responsible for operating reaming machines to create precise holes and contours in metal components. They use cutting tools and fixtures to ream holes within specified tolerances, and they monitor machine performance to ensure optimal cutting conditions. Reaming machine operators also inspect reamed components to verify accuracy, and they calibrate and maintain reaming machines to meet industry standards.

What are the qualifications for a reaming machine operator?

Most reaming machine operators have a high school diploma or equivalent. Some employers may require candidates to have a post-secondary degree in a related field, such as mechanical engineering or manufacturing. Reaming machine operators typically receive on-the-job training, and they may also complete formal training programs offered by manufacturers or trade schools.

What are the skills required for a reaming machine operator?

Reaming machine operators need to have strong mechanical skills and be able to operate reaming machines safely and efficiently. They also need to be able to read and interpret blueprints and work orders, and they should have a good understanding of quality control procedures. Additionally, reaming machine operators need to be able to work independently and as part of a team.

What is the work environment for a reaming machine operator?

Reaming machine operators typically work in manufacturing environments. They may work in factories, machine shops, or other industrial settings. The work environment can be noisy and dirty, and reaming machine operators may be exposed to hazardous materials. They may also need to work overtime or on weekends to meet production deadlines.

What is the salary for a reaming machine operator?

The salary for a reaming machine operator can vary depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for machinists and tool and die makers was $46,090 in May 2021. The lowest 10 percent earned less than $27,400, and the highest 10 percent earned more than $79,140.

What is the job outlook for a reaming machine operator?

The job outlook for reaming machine operators is expected to be good over the next few years. The demand for reaming machine operators is expected to increase as manufacturers continue to invest in automated production processes. However, the job outlook may vary depending on the industry and location.