Are you a seasoned Reduction Furnace Operator seeking a new career path? Discover our professionally built Reduction Furnace Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

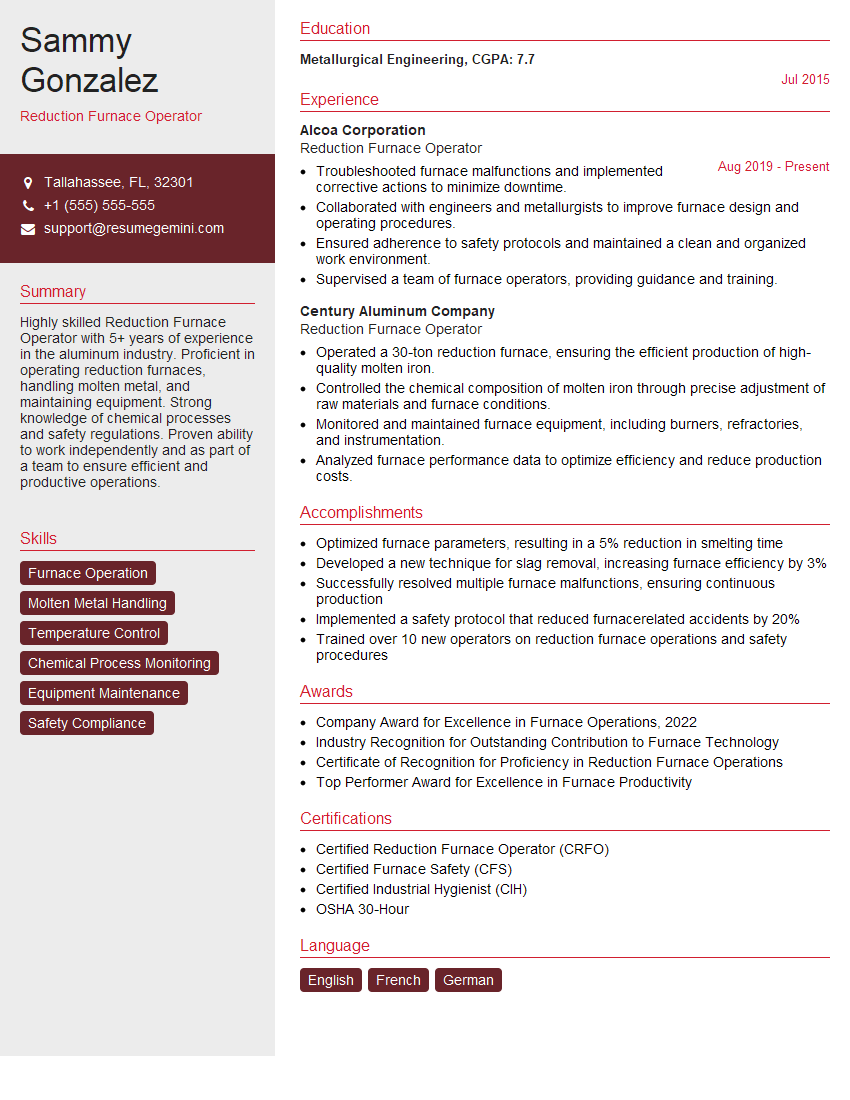

Sammy Gonzalez

Reduction Furnace Operator

Summary

Highly skilled Reduction Furnace Operator with 5+ years of experience in the aluminum industry. Proficient in operating reduction furnaces, handling molten metal, and maintaining equipment. Strong knowledge of chemical processes and safety regulations. Proven ability to work independently and as part of a team to ensure efficient and productive operations.

Education

Metallurgical Engineering

July 2015

Skills

- Furnace Operation

- Molten Metal Handling

- Temperature Control

- Chemical Process Monitoring

- Equipment Maintenance

- Safety Compliance

Work Experience

Reduction Furnace Operator

- Troubleshooted furnace malfunctions and implemented corrective actions to minimize downtime.

- Collaborated with engineers and metallurgists to improve furnace design and operating procedures.

- Ensured adherence to safety protocols and maintained a clean and organized work environment.

- Supervised a team of furnace operators, providing guidance and training.

Reduction Furnace Operator

- Operated a 30-ton reduction furnace, ensuring the efficient production of high-quality molten iron.

- Controlled the chemical composition of molten iron through precise adjustment of raw materials and furnace conditions.

- Monitored and maintained furnace equipment, including burners, refractories, and instrumentation.

- Analyzed furnace performance data to optimize efficiency and reduce production costs.

Accomplishments

- Optimized furnace parameters, resulting in a 5% reduction in smelting time

- Developed a new technique for slag removal, increasing furnace efficiency by 3%

- Successfully resolved multiple furnace malfunctions, ensuring continuous production

- Implemented a safety protocol that reduced furnacerelated accidents by 20%

- Trained over 10 new operators on reduction furnace operations and safety procedures

Awards

- Company Award for Excellence in Furnace Operations, 2022

- Industry Recognition for Outstanding Contribution to Furnace Technology

- Certificate of Recognition for Proficiency in Reduction Furnace Operations

- Top Performer Award for Excellence in Furnace Productivity

Certificates

- Certified Reduction Furnace Operator (CRFO)

- Certified Furnace Safety (CFS)

- Certified Industrial Hygienist (CIH)

- OSHA 30-Hour

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Reduction Furnace Operator

- Quantify your accomplishments and provide specific examples of your work.

- Highlight your knowledge of reduction furnace operations, molten metal handling, and safety regulations.

- Demonstrate your ability to work independently and as part of a team.

- Emphasize your commitment to continuous improvement and safety.

Essential Experience Highlights for a Strong Reduction Furnace Operator Resume

- Operate and maintain reduction furnaces according to Standard Operating Procedures

- Monitor and control furnace temperatures, gas flows, and other process parameters

- Handle molten metal safely and efficiently using cranes and ladles

- Maintain equipment and perform minor repairs to ensure optimal furnace performance

- Monitor chemical processes and make adjustments as needed to optimize production

- Adhere to all safety regulations and protocols to ensure a safe work environment

- Train and supervise junior operators

Frequently Asked Questions (FAQ’s) For Reduction Furnace Operator

What is the primary role of a Reduction Furnace Operator?

The primary role of a Reduction Furnace Operator is to operate and maintain reduction furnaces used in the production of aluminum.

What are the key skills required for this role?

Key skills for a Reduction Furnace Operator include furnace operation, molten metal handling, temperature control, chemical process monitoring, equipment maintenance, and safety compliance.

What are the educational qualifications for this role?

A degree in Metallurgical Engineering or a related field is preferred for this role.

What is the work environment like for a Reduction Furnace Operator?

Reduction Furnace Operators typically work in industrial settings, such as aluminum smelters. The work environment can be hot, noisy, and dusty.

What are the career advancement opportunities for a Reduction Furnace Operator?

With experience and additional training, Reduction Furnace Operators can advance to roles such as Production Supervisor or Furnace Manager.

What are the safety hazards associated with this role?

Reduction Furnace Operators work with high temperatures, molten metal, and hazardous chemicals. Proper safety training and adherence to safety protocols are essential to minimize risks.

What are the physical demands of this role?

Reduction Furnace Operators must be able to stand for long periods, lift heavy objects, and work in physically demanding conditions.