Are you a seasoned Refractory Specialist seeking a new career path? Discover our professionally built Refractory Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

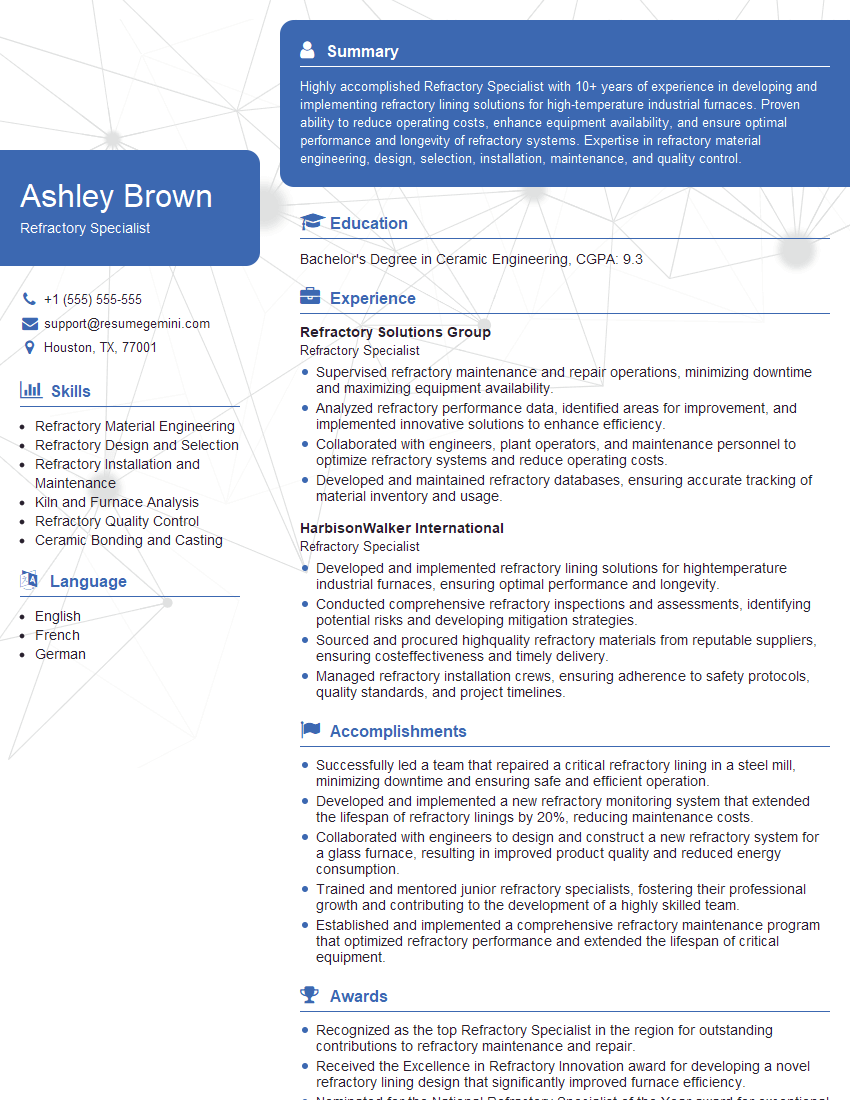

Ashley Brown

Refractory Specialist

Summary

Highly accomplished Refractory Specialist with 10+ years of experience in developing and implementing refractory lining solutions for high-temperature industrial furnaces. Proven ability to reduce operating costs, enhance equipment availability, and ensure optimal performance and longevity of refractory systems. Expertise in refractory material engineering, design, selection, installation, maintenance, and quality control.

Education

Bachelor’s Degree in Ceramic Engineering

December 2017

Skills

- Refractory Material Engineering

- Refractory Design and Selection

- Refractory Installation and Maintenance

- Kiln and Furnace Analysis

- Refractory Quality Control

- Ceramic Bonding and Casting

Work Experience

Refractory Specialist

- Supervised refractory maintenance and repair operations, minimizing downtime and maximizing equipment availability.

- Analyzed refractory performance data, identified areas for improvement, and implemented innovative solutions to enhance efficiency.

- Collaborated with engineers, plant operators, and maintenance personnel to optimize refractory systems and reduce operating costs.

- Developed and maintained refractory databases, ensuring accurate tracking of material inventory and usage.

Refractory Specialist

- Developed and implemented refractory lining solutions for hightemperature industrial furnaces, ensuring optimal performance and longevity.

- Conducted comprehensive refractory inspections and assessments, identifying potential risks and developing mitigation strategies.

- Sourced and procured highquality refractory materials from reputable suppliers, ensuring costeffectiveness and timely delivery.

- Managed refractory installation crews, ensuring adherence to safety protocols, quality standards, and project timelines.

Accomplishments

- Successfully led a team that repaired a critical refractory lining in a steel mill, minimizing downtime and ensuring safe and efficient operation.

- Developed and implemented a new refractory monitoring system that extended the lifespan of refractory linings by 20%, reducing maintenance costs.

- Collaborated with engineers to design and construct a new refractory system for a glass furnace, resulting in improved product quality and reduced energy consumption.

- Trained and mentored junior refractory specialists, fostering their professional growth and contributing to the development of a highly skilled team.

- Established and implemented a comprehensive refractory maintenance program that optimized refractory performance and extended the lifespan of critical equipment.

Awards

- Recognized as the top Refractory Specialist in the region for outstanding contributions to refractory maintenance and repair.

- Received the Excellence in Refractory Innovation award for developing a novel refractory lining design that significantly improved furnace efficiency.

- Nominated for the National Refractory Specialist of the Year award for exceptional work in the field.

- Received recognition for expertise in refractory materials and their application, as demonstrated in a peerreviewed article published in a leading industry journal.

Certificates

- Certified Refractory Specialist (CRS)

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- American Welding Society (AWS)

- American Ceramic Society (ACerS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Refractory Specialist

- Highlight your expertise in refractory material engineering and design, demonstrating your technical proficiency.

- Showcase your ability to analyze refractory performance data and implement innovative solutions to enhance efficiency.

- Emphasize your experience in managing refractory installation crews, ensuring adherence to safety protocols and quality standards.

- Quantify your accomplishments whenever possible, providing specific metrics and results that demonstrate your impact and value.

- Obtain certifications in refractory engineering or related fields to enhance your credibility and demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Refractory Specialist Resume

- Developed and implemented refractory lining solutions for high-temperature industrial furnaces, ensuring optimal performance and longevity.

- Conducted comprehensive refractory inspections and assessments, identifying potential risks and developing mitigation strategies.

- Managed refractory installation crews, ensuring adherence to safety protocols, quality standards, and project timelines.

- Supervised refractory maintenance and repair operations, minimizing downtime and maximizing equipment availability.

- Analyzed refractory performance data, identified areas for improvement, and implemented innovative solutions to enhance efficiency.

- Collaborated with engineers, plant operators, and maintenance personnel to optimize refractory systems and reduce operating costs.

Frequently Asked Questions (FAQ’s) For Refractory Specialist

What is the role of a Refractory Specialist?

A Refractory Specialist is responsible for designing, selecting, and maintaining refractory materials used in high-temperature industrial furnaces and other applications to ensure optimal performance, longevity, and cost-effectiveness.

What industries require Refractory Specialists?

Refractory Specialists are employed in various industries that utilize high-temperature processes, including steel production, glass manufacturing, cement production, and petrochemical processing.

What are the key skills required to be a successful Refractory Specialist?

Key skills for Refractory Specialists include refractory material engineering and design, installation and maintenance, kiln and furnace analysis, refractory quality control, and ceramic bonding and casting.

What is the career outlook for Refractory Specialists?

The demand for Refractory Specialists is expected to grow as industries continue to seek ways to improve the efficiency and longevity of their high-temperature processes.

What are the potential career paths for Refractory Specialists?

Refractory Specialists may advance to roles such as Refractory Engineering Manager, Plant Manager, or Technical Director.

Where can I find job openings for Refractory Specialists?

Job openings for Refractory Specialists can be found on industry-specific job boards, company websites, and through professional networking.