Are you a seasoned Remelt Worker seeking a new career path? Discover our professionally built Remelt Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

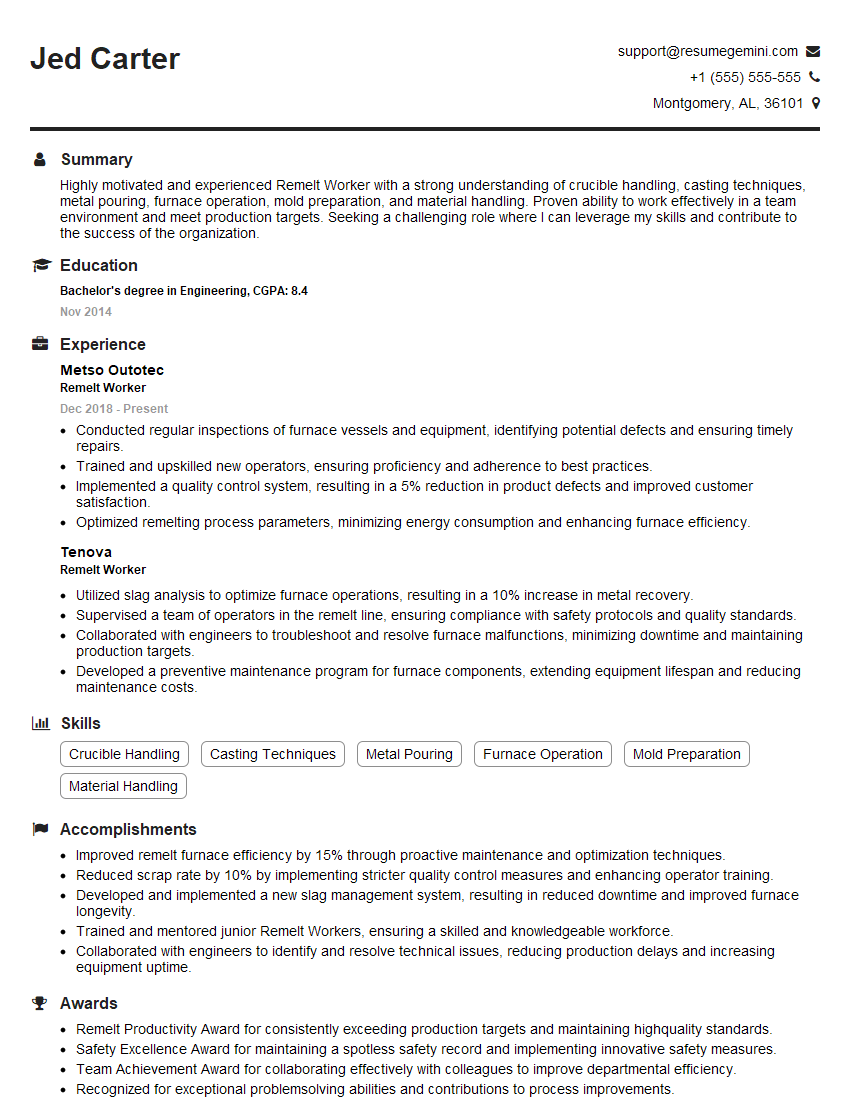

Jed Carter

Remelt Worker

Summary

Highly motivated and experienced Remelt Worker with a strong understanding of crucible handling, casting techniques, metal pouring, furnace operation, mold preparation, and material handling. Proven ability to work effectively in a team environment and meet production targets. Seeking a challenging role where I can leverage my skills and contribute to the success of the organization.

Education

Bachelor’s degree in Engineering

November 2014

Skills

- Crucible Handling

- Casting Techniques

- Metal Pouring

- Furnace Operation

- Mold Preparation

- Material Handling

Work Experience

Remelt Worker

- Conducted regular inspections of furnace vessels and equipment, identifying potential defects and ensuring timely repairs.

- Trained and upskilled new operators, ensuring proficiency and adherence to best practices.

- Implemented a quality control system, resulting in a 5% reduction in product defects and improved customer satisfaction.

- Optimized remelting process parameters, minimizing energy consumption and enhancing furnace efficiency.

Remelt Worker

- Utilized slag analysis to optimize furnace operations, resulting in a 10% increase in metal recovery.

- Supervised a team of operators in the remelt line, ensuring compliance with safety protocols and quality standards.

- Collaborated with engineers to troubleshoot and resolve furnace malfunctions, minimizing downtime and maintaining production targets.

- Developed a preventive maintenance program for furnace components, extending equipment lifespan and reducing maintenance costs.

Accomplishments

- Improved remelt furnace efficiency by 15% through proactive maintenance and optimization techniques.

- Reduced scrap rate by 10% by implementing stricter quality control measures and enhancing operator training.

- Developed and implemented a new slag management system, resulting in reduced downtime and improved furnace longevity.

- Trained and mentored junior Remelt Workers, ensuring a skilled and knowledgeable workforce.

- Collaborated with engineers to identify and resolve technical issues, reducing production delays and increasing equipment uptime.

Awards

- Remelt Productivity Award for consistently exceeding production targets and maintaining highquality standards.

- Safety Excellence Award for maintaining a spotless safety record and implementing innovative safety measures.

- Team Achievement Award for collaborating effectively with colleagues to improve departmental efficiency.

- Recognized for exceptional problemsolving abilities and contributions to process improvements.

Certificates

- Certified Remelt Worker

- OSHA Safety Certification

- ISO 9001 Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Remelt Worker

- Highlight your experience in crucible handling, casting techniques, and metal pouring.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Demonstrate your knowledge of safety protocols and regulations.

- Include any certifications or training that you have received.

Essential Experience Highlights for a Strong Remelt Worker Resume

- Prepare and maintain crucibles, furnaces, and molds for the remelting process.

- Handle and pour molten metal safely and efficiently.

- Operate furnaces to melt and refine scrap metal according to specifications.

- Cast molten metal into molds to create new products or components.

- Inspect and test finished products to ensure quality standards are met.

- Maintain a clean and organized work area.

- Follow safety protocols and regulations to prevent accidents and injuries.

Frequently Asked Questions (FAQ’s) For Remelt Worker

What is the primary role of a Remelt Worker?

The primary role of a Remelt Worker is to prepare, handle, and pour molten metal, operate furnaces, and cast metal into molds to create new products or components.

What are the key skills required for a Remelt Worker?

The key skills required for a Remelt Worker include crucible handling, casting techniques, metal pouring, furnace operation, mold preparation, and material handling.

What are the educational qualifications required to become a Remelt Worker?

A high school diploma or equivalent is typically required to become a Remelt Worker. Some employers may prefer candidates with a post-secondary diploma or certificate in a related field.

What are the career prospects for a Remelt Worker?

Remelt Workers can advance their careers by gaining experience and becoming certified in their field. They may also move into supervisory roles or management positions.

What are the challenges faced by Remelt Workers?

Remelt Workers face challenges such as working with molten metal, which can be dangerous. They also need to be able to work in a fast-paced environment and meet production targets.

What is the work environment of a Remelt Worker?

Remelt Workers typically work in industrial settings, such as foundries or metalworking shops. They may work in a team environment or independently.