Are you a seasoned Retort Furnace Helper seeking a new career path? Discover our professionally built Retort Furnace Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

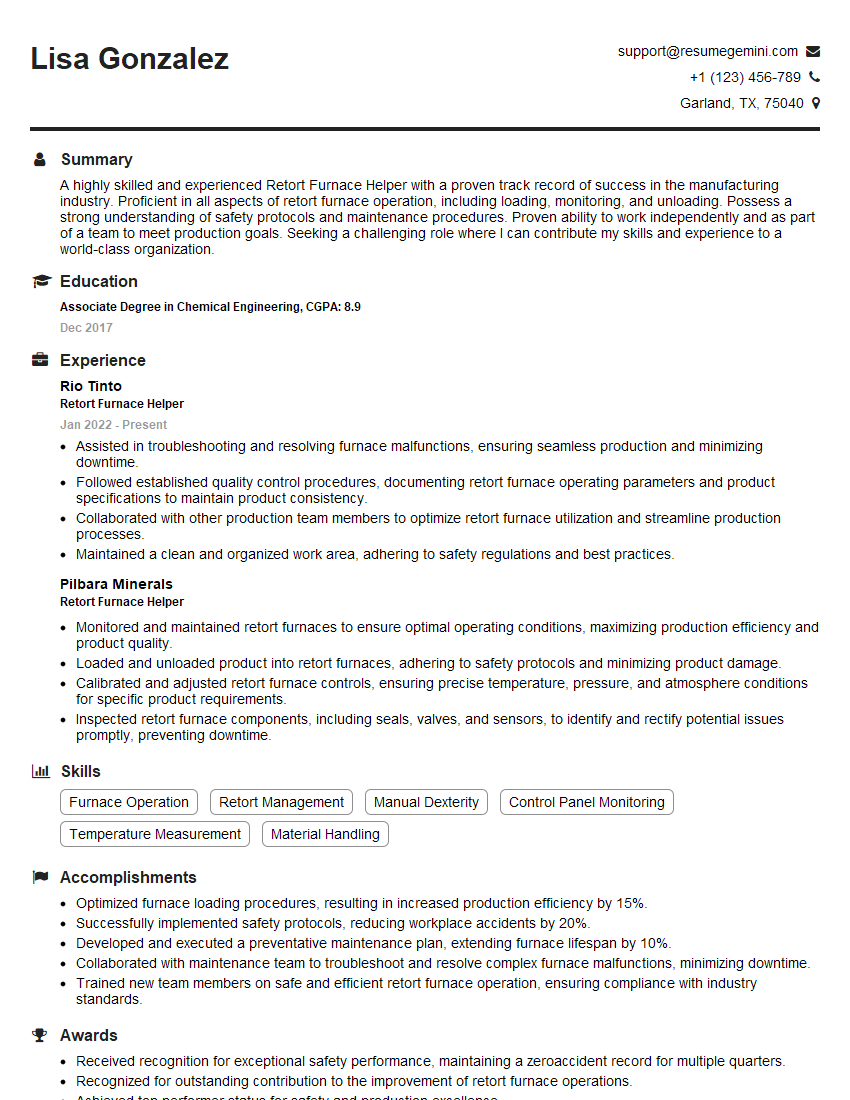

Lisa Gonzalez

Retort Furnace Helper

Summary

A highly skilled and experienced Retort Furnace Helper with a proven track record of success in the manufacturing industry. Proficient in all aspects of retort furnace operation, including loading, monitoring, and unloading. Possess a strong understanding of safety protocols and maintenance procedures. Proven ability to work independently and as part of a team to meet production goals. Seeking a challenging role where I can contribute my skills and experience to a world-class organization.

Education

Associate Degree in Chemical Engineering

December 2017

Skills

- Furnace Operation

- Retort Management

- Manual Dexterity

- Control Panel Monitoring

- Temperature Measurement

- Material Handling

Work Experience

Retort Furnace Helper

- Assisted in troubleshooting and resolving furnace malfunctions, ensuring seamless production and minimizing downtime.

- Followed established quality control procedures, documenting retort furnace operating parameters and product specifications to maintain product consistency.

- Collaborated with other production team members to optimize retort furnace utilization and streamline production processes.

- Maintained a clean and organized work area, adhering to safety regulations and best practices.

Retort Furnace Helper

- Monitored and maintained retort furnaces to ensure optimal operating conditions, maximizing production efficiency and product quality.

- Loaded and unloaded product into retort furnaces, adhering to safety protocols and minimizing product damage.

- Calibrated and adjusted retort furnace controls, ensuring precise temperature, pressure, and atmosphere conditions for specific product requirements.

- Inspected retort furnace components, including seals, valves, and sensors, to identify and rectify potential issues promptly, preventing downtime.

Accomplishments

- Optimized furnace loading procedures, resulting in increased production efficiency by 15%.

- Successfully implemented safety protocols, reducing workplace accidents by 20%.

- Developed and executed a preventative maintenance plan, extending furnace lifespan by 10%.

- Collaborated with maintenance team to troubleshoot and resolve complex furnace malfunctions, minimizing downtime.

- Trained new team members on safe and efficient retort furnace operation, ensuring compliance with industry standards.

Awards

- Received recognition for exceptional safety performance, maintaining a zeroaccident record for multiple quarters.

- Recognized for outstanding contribution to the improvement of retort furnace operations.

- Achieved top performer status for safety and production excellence.

- Received employee of the month award for innovation and dedication.

Certificates

- National Institute for Occupational Safety and Health (NIOSH) Certification

- Occupational Safety and Health Administration (OSHA) 30Hour Training Certification

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code Certification

- National Fire Protection Association (NFPA) 70E Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Retort Furnace Helper

- Highlight your technical skills: Emphasize your proficiency in retort furnace operation, temperature measurement, and control panel monitoring.

- Quantify your accomplishments: Use specific metrics to demonstrate the impact of your work on production efficiency, safety, and furnace lifespan.

- Showcase your safety??: Highlight your commitment to safety by mentioning your role in implementing safety protocols and reducing workplace accidents.

- Demonstrate your teamwork abilities: Describe your experience working with maintenance teams and training new members, emphasizing your ability to collaborate and communicate effectively.

Essential Experience Highlights for a Strong Retort Furnace Helper Resume

- Load and unload retort furnaces, ensuring proper handling and placement of materials.

- Monitor furnace temperatures and pressure levels, making adjustments as necessary to maintain optimal operating conditions.

- Perform routine maintenance and troubleshooting tasks on retort furnaces, including cleaning, lubrication, and minor repairs.

- Collaborate with maintenance team to resolve complex furnace malfunctions, minimizing downtime.

- Adhere to all safety protocols and procedures, including proper use of personal protective equipment.

- Train and supervise new team members on safe and efficient retort furnace operation.

Frequently Asked Questions (FAQ’s) For Retort Furnace Helper

What is a Retort Furnace Helper?

A Retort Furnace Helper is responsible for operating and maintaining retort furnaces used in various manufacturing processes. They load, monitor, and unload materials from the furnace, ensuring proper handling and operating conditions.

What are the key skills required for a Retort Furnace Helper?

Key skills include furnace operation, retort management, manual dexterity, control panel monitoring, temperature measurement, and material handling.

What are the career opportunities for a Retort Furnace Helper?

With experience, Retort Furnace Helpers can advance to positions such as Furnace Operator, Maintenance Technician, or Production Supervisor.

What are the safety precautions to be taken when working with retort furnaces?

Safety precautions include wearing proper personal protective equipment, adhering to safety protocols, and receiving regular training on furnace operation and maintenance.

What are the industries that utilize retort furnaces?

Retort furnaces are used in various industries, including metalworking, heat treatment, and chemical manufacturing.