Are you a seasoned Ribbing Machine Operator seeking a new career path? Discover our professionally built Ribbing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

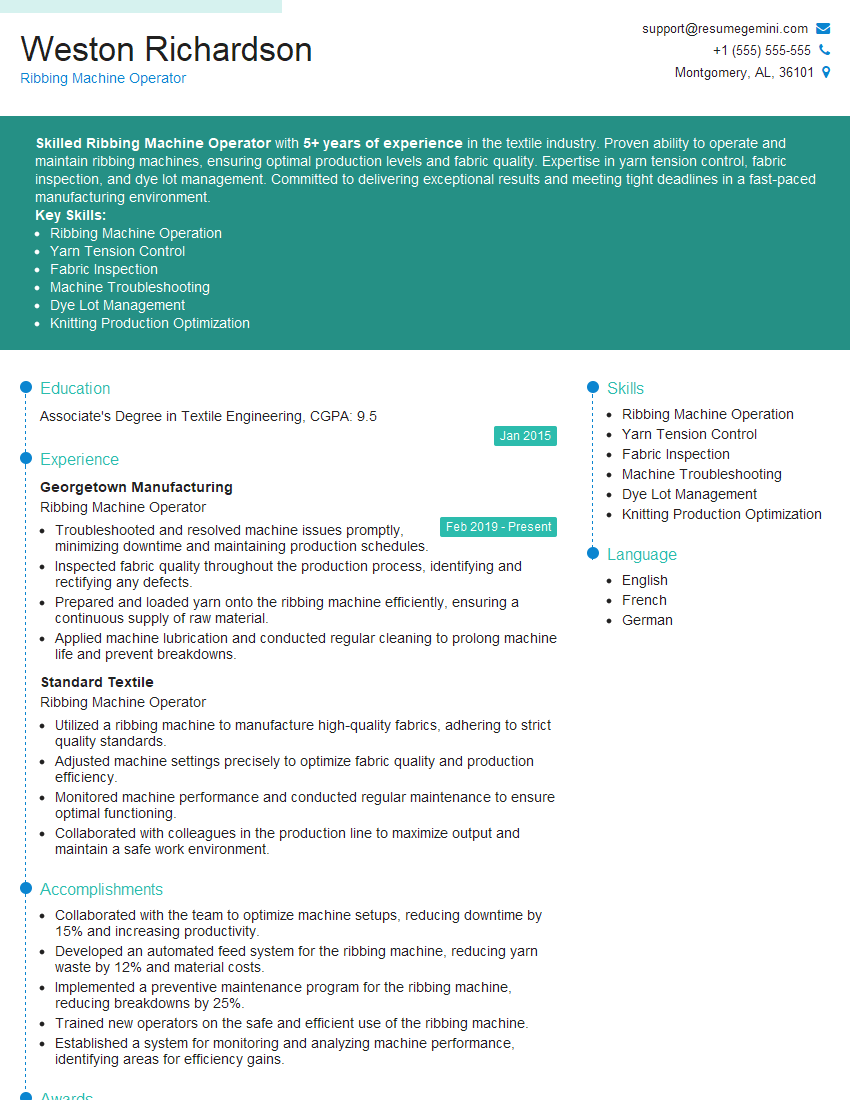

Weston Richardson

Ribbing Machine Operator

Summary

Skilled Ribbing Machine Operator with 5+ years of experience in the textile industry. Proven ability to operate and maintain ribbing machines, ensuring optimal production levels and fabric quality. Expertise in yarn tension control, fabric inspection, and dye lot management. Committed to delivering exceptional results and meeting tight deadlines in a fast-paced manufacturing environment.

Key Skills:

- Ribbing Machine Operation

- Yarn Tension Control

- Fabric Inspection

- Machine Troubleshooting

- Dye Lot Management

- Knitting Production Optimization

Education

Associate’s Degree in Textile Engineering

January 2015

Skills

- Ribbing Machine Operation

- Yarn Tension Control

- Fabric Inspection

- Machine Troubleshooting

- Dye Lot Management

- Knitting Production Optimization

Work Experience

Ribbing Machine Operator

- Troubleshooted and resolved machine issues promptly, minimizing downtime and maintaining production schedules.

- Inspected fabric quality throughout the production process, identifying and rectifying any defects.

- Prepared and loaded yarn onto the ribbing machine efficiently, ensuring a continuous supply of raw material.

- Applied machine lubrication and conducted regular cleaning to prolong machine life and prevent breakdowns.

Ribbing Machine Operator

- Utilized a ribbing machine to manufacture high-quality fabrics, adhering to strict quality standards.

- Adjusted machine settings precisely to optimize fabric quality and production efficiency.

- Monitored machine performance and conducted regular maintenance to ensure optimal functioning.

- Collaborated with colleagues in the production line to maximize output and maintain a safe work environment.

Accomplishments

- Collaborated with the team to optimize machine setups, reducing downtime by 15% and increasing productivity.

- Developed an automated feed system for the ribbing machine, reducing yarn waste by 12% and material costs.

- Implemented a preventive maintenance program for the ribbing machine, reducing breakdowns by 25%.

- Trained new operators on the safe and efficient use of the ribbing machine.

- Established a system for monitoring and analyzing machine performance, identifying areas for efficiency gains.

Awards

- Recognized for maintaining 98% efficiency on the ribbing machine, exceeding production targets by 10%.

- Awarded Operator of the Month for consistently delivering highquality ribbed products with minimal defects.

- Recognized for innovative use of the ribbing machine to create unique and intricate fabric textures.

- Commended for exceptional safety practices in the operation of the ribbing machine.

Certificates

- Certified Knitting Technician (CKT)

- Six Sigma Green Belt

- OSHA 10-Hour Safety Certification

- LEAN Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Ribbing Machine Operator

- Highlight Your Expertise: Showcase your proficiency in ribbing machine operation, yarn tension control, and fabric inspection.

- Quantify Your Achievements: Use specific metrics to demonstrate your impact on production efficiency and fabric quality.

- Emphasize Continuous Improvement: Describe your commitment to learning new techniques and optimizing processes.

- Tailor Your Resume: Customize your resume to match the specific requirements of the job you are applying for.

- Proofread Carefully: Ensure your resume is free of errors and presents a professional image.

Essential Experience Highlights for a Strong Ribbing Machine Operator Resume

- Operate and monitor ribbing machines to produce high-quality knitted fabrics.

- Maintain and troubleshoot machines to ensure optimal performance and minimize downtime.

- Control yarn tension to achieve desired fabric specifications and prevent yarn breakage.

- Inspect fabrics for defects and ensure compliance with quality standards.

- Manage dye lots to ensure color consistency and prevent contamination.

- Optimize production processes to increase efficiency and reduce waste.

- Collaborate with other team members to maintain a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Ribbing Machine Operator

What is a Ribbing Machine Operator?

A Ribbing Machine Operator is responsible for operating and maintaining ribbing machines to produce knitted fabrics. They ensure the machines are running smoothly, monitor yarn tension, inspect fabrics for defects, and troubleshoot any issues that arise.

What skills are required to be a Ribbing Machine Operator?

Essential skills include ribbing machine operation, yarn tension control, fabric inspection, machine troubleshooting, dye lot management, and knitting production optimization.

What is the work environment of a Ribbing Machine Operator like?

Ribbing Machine Operators typically work in manufacturing facilities, operating machines in a fast-paced environment. They may work shifts and be exposed to noise and moving machinery.

What are the career prospects for a Ribbing Machine Operator?

With experience and additional training, Ribbing Machine Operators can advance to supervisory roles or become Knitting Technicians or Textile Engineers.

How can I become a Ribbing Machine Operator?

Most Ribbing Machine Operators receive on-the-job training. However, some employers may prefer candidates with an Associate’s Degree in Textile Engineering or related field.

What is the salary range for a Ribbing Machine Operator?

The salary range for Ribbing Machine Operators varies depending on experience, location, and company size. According to Indeed, the average salary for a Ribbing Machine Operator in the United States is around $20-$30 per hour.

What are the benefits of being a Ribbing Machine Operator?

Benefits of being a Ribbing Machine Operator include job security, opportunities for advancement, and the satisfaction of working in a manufacturing environment.

What are the challenges of being a Ribbing Machine Operator?

Challenges of being a Ribbing Machine Operator include working in a fast-paced environment, exposure to noise and moving machinery, and the need for physical strength and dexterity.