Are you a seasoned Rim Turning Finisher seeking a new career path? Discover our professionally built Rim Turning Finisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

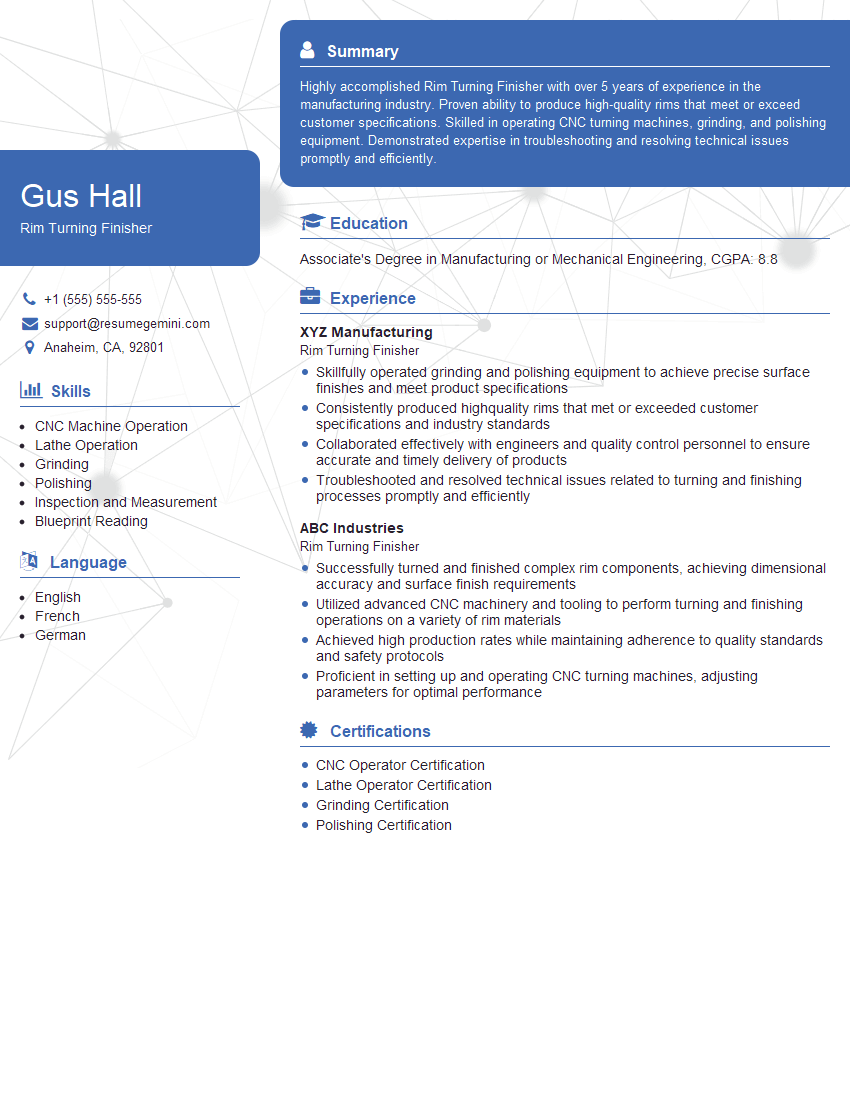

Gus Hall

Rim Turning Finisher

Summary

Highly accomplished Rim Turning Finisher with over 5 years of experience in the manufacturing industry. Proven ability to produce high-quality rims that meet or exceed customer specifications. Skilled in operating CNC turning machines, grinding, and polishing equipment. Demonstrated expertise in troubleshooting and resolving technical issues promptly and efficiently.

Education

Associate’s Degree in Manufacturing or Mechanical Engineering

April 2017

Skills

- CNC Machine Operation

- Lathe Operation

- Grinding

- Polishing

- Inspection and Measurement

- Blueprint Reading

Work Experience

Rim Turning Finisher

- Skillfully operated grinding and polishing equipment to achieve precise surface finishes and meet product specifications

- Consistently produced highquality rims that met or exceeded customer specifications and industry standards

- Collaborated effectively with engineers and quality control personnel to ensure accurate and timely delivery of products

- Troubleshooted and resolved technical issues related to turning and finishing processes promptly and efficiently

Rim Turning Finisher

- Successfully turned and finished complex rim components, achieving dimensional accuracy and surface finish requirements

- Utilized advanced CNC machinery and tooling to perform turning and finishing operations on a variety of rim materials

- Achieved high production rates while maintaining adherence to quality standards and safety protocols

- Proficient in setting up and operating CNC turning machines, adjusting parameters for optimal performance

Certificates

- CNC Operator Certification

- Lathe Operator Certification

- Grinding Certification

- Polishing Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rim Turning Finisher

- Quantify your accomplishments and provide specific examples to demonstrate your skills.

- Highlight your knowledge of CNC turning machines and finishing techniques.

- Showcase your ability to collaborate effectively with others.

- Tailor your resume to the specific requirements of the job you’re applying for.

Essential Experience Highlights for a Strong Rim Turning Finisher Resume

- Set up and operate CNC turning machines to produce complex rim components.

- Grind and polish rims to achieve precise surface finishes and meet product specifications.

- Inspect and measure finished rims to ensure dimensional accuracy and conformance to quality standards.

- Collaborate with engineers and quality control personnel to ensure accurate and timely delivery of products.

- Troubleshoot and resolve technical issues related to turning and finishing processes.

- Adhere to safety protocols and maintain a clean and organized work area.

- Keep up-to-date on industry best practices and new technologies.

Frequently Asked Questions (FAQ’s) For Rim Turning Finisher

What is the primary role of a Rim Turning Finisher?

Rim Turning Finishers are responsible for turning and finishing complex rim components, ensuring dimensional accuracy and surface finish requirements are met. They utilize advanced CNC machinery and tooling to perform turning and finishing operations on a variety of rim materials, achieving high production rates while maintaining adherence to quality standards and safety protocols.

What are the essential skills for a successful Rim Turning Finisher?

Essential skills for a Rim Turning Finisher include CNC machine operation, lathe operation, grinding, polishing, inspection and measurement, blueprint reading, and troubleshooting. They must be proficient in setting up and operating CNC turning machines, adjusting parameters for optimal performance, and skillfully operating grinding and polishing equipment to achieve precise surface finishes.

What is the work environment of a Rim Turning Finisher like?

Rim Turning Finishers typically work in manufacturing facilities, often in a workshop or production environment. They operate CNC turning machines, grinders, and other equipment in a hands-on capacity, requiring attention to detail, precision, and safety. They may work as part of a team or independently, collaborating with engineers, quality control personnel, and other professionals.

What career advancement opportunities are available for Rim Turning Finishers?

With experience and skill development, Rim Turning Finishers can advance to supervisory roles, such as Lead Finisher or Production Supervisor. They may also specialize in specific areas, such as CNC programming or quality control. Additionally, they can pursue further education to enhance their technical knowledge and career prospects.

What are the typical salary expectations for Rim Turning Finishers?

Salary expectations for Rim Turning Finishers can vary depending on factors such as experience, skill level, location, and industry. According to Indeed, the average salary for Rim Turning Finishers in the United States is around $25 per hour or $52,000 per year. Salaries may be higher in specialized fields or for individuals with extensive experience and expertise.

What are the key qualities of a successful Rim Turning Finisher?

Successful Rim Turning Finishers possess a strong work ethic, attention to detail, and a commitment to quality. They are proficient in operating and maintaining CNC turning machines and other equipment, and have a good understanding of manufacturing processes. They are also able to work independently and as part of a team, and are adaptable to changing work environments.

What are the challenges faced by Rim Turning Finishers?

Rim Turning Finishers may face challenges related to meeting tight production deadlines, ensuring accuracy and quality in their work, and staying up-to-date with advancements in technology. They may also encounter physical demands associated with operating heavy machinery and working in a manufacturing environment.