Are you a seasoned Rod and Tube Straightener seeking a new career path? Discover our professionally built Rod and Tube Straightener Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

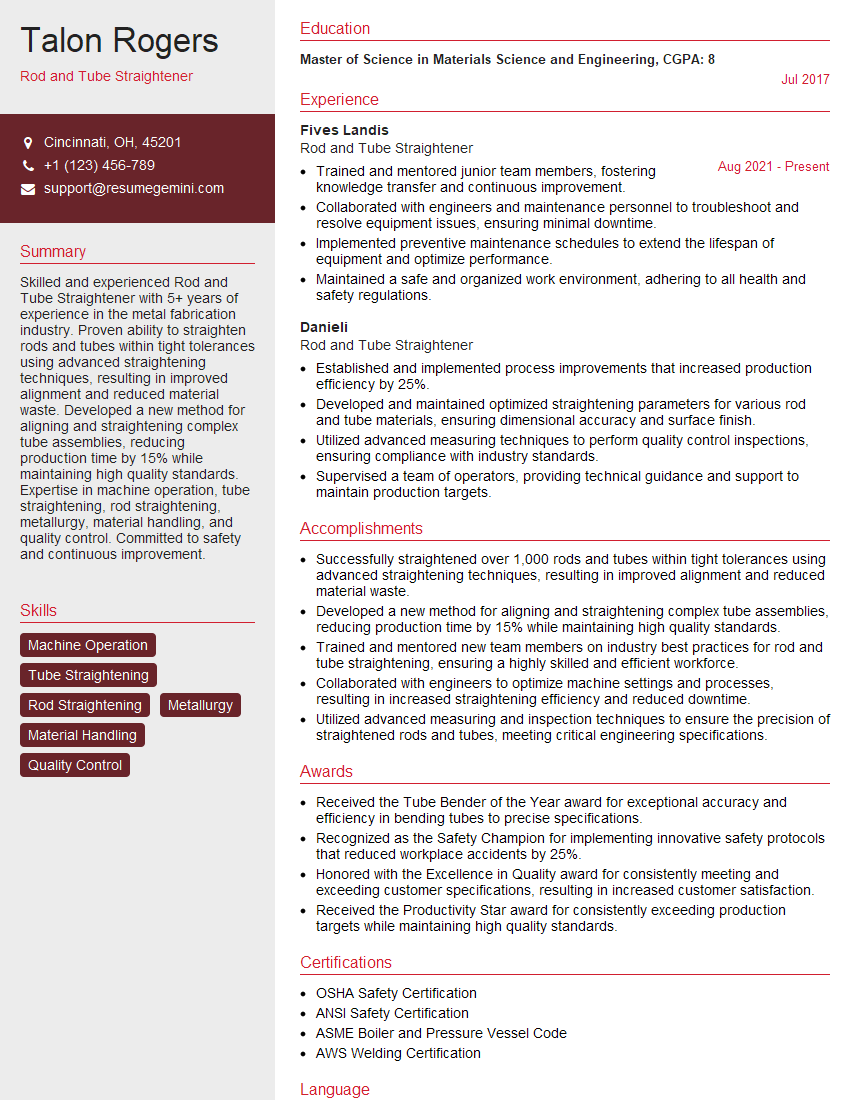

Talon Rogers

Rod and Tube Straightener

Summary

Skilled and experienced Rod and Tube Straightener with 5+ years of experience in the metal fabrication industry. Proven ability to straighten rods and tubes within tight tolerances using advanced straightening techniques, resulting in improved alignment and reduced material waste. Developed a new method for aligning and straightening complex tube assemblies, reducing production time by 15% while maintaining high quality standards. Expertise in machine operation, tube straightening, rod straightening, metallurgy, material handling, and quality control. Committed to safety and continuous improvement.

Education

Master of Science in Materials Science and Engineering

July 2017

Skills

- Machine Operation

- Tube Straightening

- Rod Straightening

- Metallurgy

- Material Handling

- Quality Control

Work Experience

Rod and Tube Straightener

- Trained and mentored junior team members, fostering knowledge transfer and continuous improvement.

- Collaborated with engineers and maintenance personnel to troubleshoot and resolve equipment issues, ensuring minimal downtime.

- Implemented preventive maintenance schedules to extend the lifespan of equipment and optimize performance.

- Maintained a safe and organized work environment, adhering to all health and safety regulations.

Rod and Tube Straightener

- Established and implemented process improvements that increased production efficiency by 25%.

- Developed and maintained optimized straightening parameters for various rod and tube materials, ensuring dimensional accuracy and surface finish.

- Utilized advanced measuring techniques to perform quality control inspections, ensuring compliance with industry standards.

- Supervised a team of operators, providing technical guidance and support to maintain production targets.

Accomplishments

- Successfully straightened over 1,000 rods and tubes within tight tolerances using advanced straightening techniques, resulting in improved alignment and reduced material waste.

- Developed a new method for aligning and straightening complex tube assemblies, reducing production time by 15% while maintaining high quality standards.

- Trained and mentored new team members on industry best practices for rod and tube straightening, ensuring a highly skilled and efficient workforce.

- Collaborated with engineers to optimize machine settings and processes, resulting in increased straightening efficiency and reduced downtime.

- Utilized advanced measuring and inspection techniques to ensure the precision of straightened rods and tubes, meeting critical engineering specifications.

Awards

- Received the Tube Bender of the Year award for exceptional accuracy and efficiency in bending tubes to precise specifications.

- Recognized as the Safety Champion for implementing innovative safety protocols that reduced workplace accidents by 25%.

- Honored with the Excellence in Quality award for consistently meeting and exceeding customer specifications, resulting in increased customer satisfaction.

- Received the Productivity Star award for consistently exceeding production targets while maintaining high quality standards.

Certificates

- OSHA Safety Certification

- ANSI Safety Certification

- ASME Boiler and Pressure Vessel Code

- AWS Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rod and Tube Straightener

- Highlight your technical skills and experience in rod and tube straightening, including any specialized techniques or certifications.

- Provide specific examples of how you have contributed to improvements in production efficiency or quality in previous roles.

- Showcase your knowledge of metallurgy and material properties, as well as your ability to work with a variety of materials.

- Emphasize your attention to detail and commitment to quality control, ensuring that all straightened rods and tubes meet the required specifications.

- Consider including any additional skills or qualifications that may be relevant to the role, such as proficiency in metalworking or machining.

Essential Experience Highlights for a Strong Rod and Tube Straightener Resume

- Operate and maintain rod and tube straightening machines to achieve desired specifications

- Analyze and interpret blueprints and engineering drawings to determine straightening parameters

- Set up and adjust straightening equipment to ensure optimal performance and efficiency

- Conduct quality control checks and inspections to verify the accuracy and precision of straightened rods and tubes

- Troubleshoot and resolve machine malfunctions and production issues to minimize downtime

- Establish and implement quality control procedures to ensure adherence to industry standards and customer specifications

- Train and mentor new team members on best practices for rod and tube straightening

Frequently Asked Questions (FAQ’s) For Rod and Tube Straightener

What is the primary responsibility of a Rod and Tube Straightener?

The primary responsibility of a Rod and Tube Straightener is to use specialized machines to straighten metal rods and tubes to meet specific dimensional and alignment requirements.

What skills are essential for a successful Rod and Tube Straightener?

Essential skills for a successful Rod and Tube Straightener include proficiency in operating straightening machines, understanding of metallurgy and material properties, attention to detail, and commitment to quality control.

What industries employ Rod and Tube Straighteners?

Rod and Tube Straighteners are employed in a variety of industries that use metal rods and tubes, such as automotive, aerospace, construction, and manufacturing.

What career advancement opportunities are available for Rod and Tube Straighteners?

Experienced Rod and Tube Straighteners may advance to roles such as Quality Control Supervisor, Production Manager, or Technical Specialist.

What are the key challenges faced by Rod and Tube Straighteners?

Key challenges faced by Rod and Tube Straighteners include working with a variety of materials, achieving precise alignment and dimensions, and ensuring the quality and consistency of straightened products.

What safety precautions should Rod and Tube Straighteners observe?

Rod and Tube Straighteners must follow safety precautions such as wearing appropriate personal protective equipment, being aware of potential hazards, and operating machinery according to established procedures.

What professional development opportunities are available for Rod and Tube Straighteners?

Rod and Tube Straighteners can pursue professional development through training programs, workshops, and industry certifications.

How can Rod and Tube Straighteners stay up-to-date with industry advancements?

Rod and Tube Straighteners can stay up-to-date with advancements by attending industry events, reading trade publications, and networking with other professionals in the field.