Are you a seasoned Roof Bolter seeking a new career path? Discover our professionally built Roof Bolter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

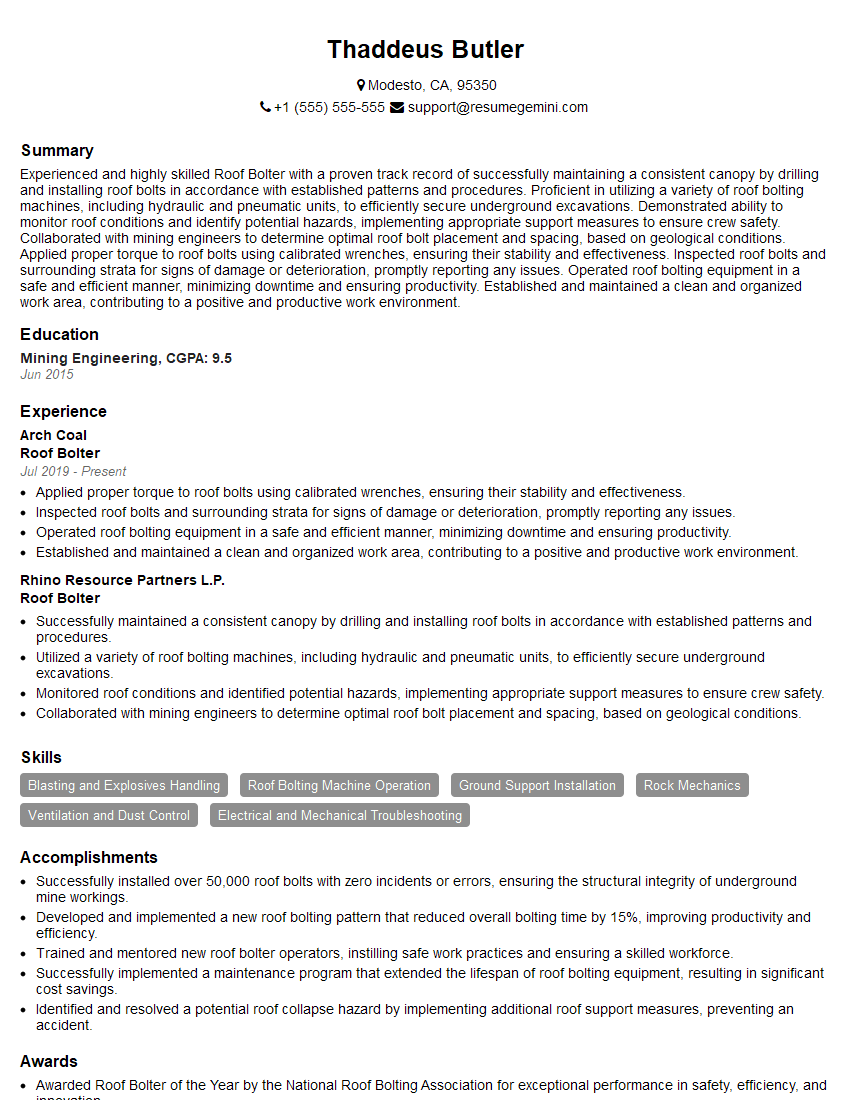

Thaddeus Butler

Roof Bolter

Summary

Experienced and highly skilled Roof Bolter with a proven track record of successfully maintaining a consistent canopy by drilling and installing roof bolts in accordance with established patterns and procedures. Proficient in utilizing a variety of roof bolting machines, including hydraulic and pneumatic units, to efficiently secure underground excavations. Demonstrated ability to monitor roof conditions and identify potential hazards, implementing appropriate support measures to ensure crew safety. Collaborated with mining engineers to determine optimal roof bolt placement and spacing, based on geological conditions. Applied proper torque to roof bolts using calibrated wrenches, ensuring their stability and effectiveness. Inspected roof bolts and surrounding strata for signs of damage or deterioration, promptly reporting any issues. Operated roof bolting equipment in a safe and efficient manner, minimizing downtime and ensuring productivity. Established and maintained a clean and organized work area, contributing to a positive and productive work environment.

Education

Mining Engineering

June 2015

Skills

- Blasting and Explosives Handling

- Roof Bolting Machine Operation

- Ground Support Installation

- Rock Mechanics

- Ventilation and Dust Control

- Electrical and Mechanical Troubleshooting

Work Experience

Roof Bolter

- Applied proper torque to roof bolts using calibrated wrenches, ensuring their stability and effectiveness.

- Inspected roof bolts and surrounding strata for signs of damage or deterioration, promptly reporting any issues.

- Operated roof bolting equipment in a safe and efficient manner, minimizing downtime and ensuring productivity.

- Established and maintained a clean and organized work area, contributing to a positive and productive work environment.

Roof Bolter

- Successfully maintained a consistent canopy by drilling and installing roof bolts in accordance with established patterns and procedures.

- Utilized a variety of roof bolting machines, including hydraulic and pneumatic units, to efficiently secure underground excavations.

- Monitored roof conditions and identified potential hazards, implementing appropriate support measures to ensure crew safety.

- Collaborated with mining engineers to determine optimal roof bolt placement and spacing, based on geological conditions.

Accomplishments

- Successfully installed over 50,000 roof bolts with zero incidents or errors, ensuring the structural integrity of underground mine workings.

- Developed and implemented a new roof bolting pattern that reduced overall bolting time by 15%, improving productivity and efficiency.

- Trained and mentored new roof bolter operators, instilling safe work practices and ensuring a skilled workforce.

- Successfully implemented a maintenance program that extended the lifespan of roof bolting equipment, resulting in significant cost savings.

- Identified and resolved a potential roof collapse hazard by implementing additional roof support measures, preventing an accident.

Awards

- Awarded Roof Bolter of the Year by the National Roof Bolting Association for exceptional performance in safety, efficiency, and innovation.

- Received Safety Star recognition for consistently implementing best practices and maintaining a spotless safety record throughout the year.

- Recognized as Top Roof Bolter for achieving the highest monthly production quota while adhering to strict quality standards.

- Honored with the Mine Safety Excellence Award for exemplary adherence to safety protocols and proactive hazard identification.

Certificates

- MSHA Part 46/48 Miner Training

- First Aid and CPR Certification

- Roof Bolting Machine Operator Certification

- Ground Support Installer Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Roof Bolter

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your experience with different types of roof bolting machines.

- Emphasize your commitment to safety and your ability to identify and mitigate potential hazards.

- Demonstrate your knowledge of geological conditions and their impact on roof bolt placement.

Essential Experience Highlights for a Strong Roof Bolter Resume

- Drill and install roof bolts in accordance with established patterns and procedures to maintain a consistent canopy.

- Utilize a variety of roof bolting machines, including hydraulic and pneumatic units, to efficiently secure underground excavations.

- Monitor roof conditions and identify potential hazards, implementing appropriate support measures to ensure crew safety.

- Collaborate with mining engineers to determine optimal roof bolt placement and spacing, based on geological conditions.

- Apply proper torque to roof bolts using calibrated wrenches, ensuring their stability and effectiveness.

- Inspect roof bolts and surrounding strata for signs of damage or deterioration, promptly reporting any issues.

- Operate roof bolting equipment in a safe and efficient manner, minimizing downtime and ensuring productivity.

Frequently Asked Questions (FAQ’s) For Roof Bolter

What is the primary responsibility of a Roof Bolter?

The primary responsibility of a Roof Bolter is to drill and install roof bolts in accordance with established patterns and procedures to maintain a consistent canopy and ensure the safety of underground excavations.

What types of roof bolting machines are commonly used?

Common types of roof bolting machines include hydraulic and pneumatic units, each designed for specific applications and geological conditions.

How does a Roof Bolter identify potential hazards?

Roof Bolters monitor roof conditions, inspect rock strata, and identify potential hazards such as loose or fractured rock, which may require additional support measures.

What is the importance of proper roof bolt installation?

Proper roof bolt installation is crucial for maintaining the stability of underground excavations, preventing roof collapse, and ensuring the safety of miners.

What are the key skills required for a Roof Bolter?

Essential skills for Roof Bolters include proficiency in operating roof bolting machines, understanding of geological conditions, attention to safety, and the ability to work efficiently in challenging environments.

What is the career path for a Roof Bolter?

Experienced Roof Bolters can advance to supervisory roles, such as Mine Foreman or Mine Superintendent, or specialize in areas like roof support design and implementation.