Are you a seasoned Rotary Kiln Operator seeking a new career path? Discover our professionally built Rotary Kiln Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

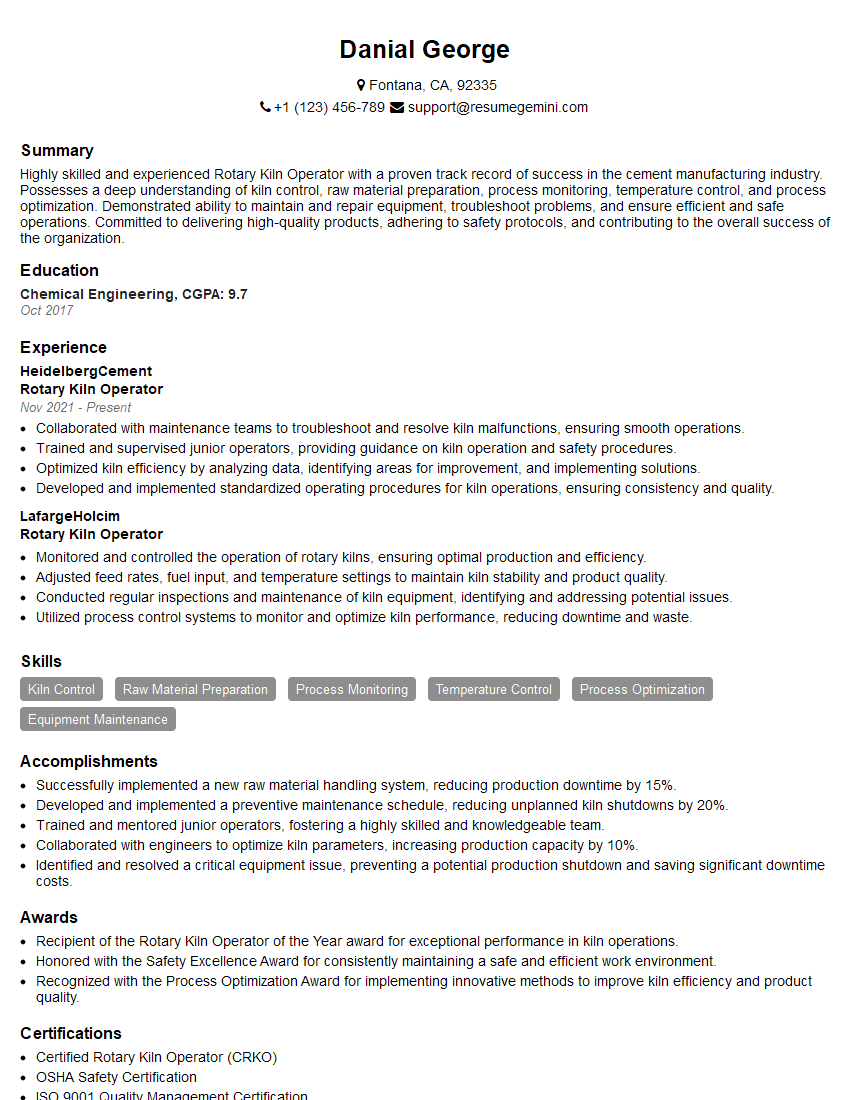

Danial George

Rotary Kiln Operator

Summary

Highly skilled and experienced Rotary Kiln Operator with a proven track record of success in the cement manufacturing industry. Possesses a deep understanding of kiln control, raw material preparation, process monitoring, temperature control, and process optimization. Demonstrated ability to maintain and repair equipment, troubleshoot problems, and ensure efficient and safe operations. Committed to delivering high-quality products, adhering to safety protocols, and contributing to the overall success of the organization.

Education

Chemical Engineering

October 2017

Skills

- Kiln Control

- Raw Material Preparation

- Process Monitoring

- Temperature Control

- Process Optimization

- Equipment Maintenance

Work Experience

Rotary Kiln Operator

- Collaborated with maintenance teams to troubleshoot and resolve kiln malfunctions, ensuring smooth operations.

- Trained and supervised junior operators, providing guidance on kiln operation and safety procedures.

- Optimized kiln efficiency by analyzing data, identifying areas for improvement, and implementing solutions.

- Developed and implemented standardized operating procedures for kiln operations, ensuring consistency and quality.

Rotary Kiln Operator

- Monitored and controlled the operation of rotary kilns, ensuring optimal production and efficiency.

- Adjusted feed rates, fuel input, and temperature settings to maintain kiln stability and product quality.

- Conducted regular inspections and maintenance of kiln equipment, identifying and addressing potential issues.

- Utilized process control systems to monitor and optimize kiln performance, reducing downtime and waste.

Accomplishments

- Successfully implemented a new raw material handling system, reducing production downtime by 15%.

- Developed and implemented a preventive maintenance schedule, reducing unplanned kiln shutdowns by 20%.

- Trained and mentored junior operators, fostering a highly skilled and knowledgeable team.

- Collaborated with engineers to optimize kiln parameters, increasing production capacity by 10%.

- Identified and resolved a critical equipment issue, preventing a potential production shutdown and saving significant downtime costs.

Awards

- Recipient of the Rotary Kiln Operator of the Year award for exceptional performance in kiln operations.

- Honored with the Safety Excellence Award for consistently maintaining a safe and efficient work environment.

- Recognized with the Process Optimization Award for implementing innovative methods to improve kiln efficiency and product quality.

Certificates

- Certified Rotary Kiln Operator (CRKO)

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rotary Kiln Operator

- Highlight your technical skills and experience in kiln operation and process optimization.

- Quantify your accomplishments with specific metrics to demonstrate your impact on production and efficiency.

- Showcase your ability to troubleshoot and resolve operational issues to ensure smooth kiln operation.

- Emphasize your commitment to safety and compliance with industry regulations.

Essential Experience Highlights for a Strong Rotary Kiln Operator Resume

- Operate and monitor rotary kilns to produce cement clinker

- Control kiln temperature, speed, and feed rates to optimize production efficiency

- Prepare and blend raw materials according to specified proportions

- Monitor process parameters and adjust settings to maintain desired product quality

- Identify and troubleshoot equipment malfunctions, and perform routine maintenance and repairs

- Collaborate with other team members to ensure smooth and efficient operations

- Maintain a clean and safe work environment, and adhere to all safety regulations

Frequently Asked Questions (FAQ’s) For Rotary Kiln Operator

What is the primary role of a Rotary Kiln Operator?

A Rotary Kiln Operator is responsible for operating and monitoring rotary kilns to produce cement clinker, a key component in the manufacturing of cement.

What are the key skills required for a Rotary Kiln Operator?

Essential skills include kiln control, raw material preparation, process monitoring, temperature control, process optimization, and equipment maintenance.

What are the typical job responsibilities of a Rotary Kiln Operator?

Duties typically involve operating and monitoring rotary kilns, controlling process parameters, preparing and blending raw materials, troubleshooting equipment issues, and maintaining a safe work environment.

What is the educational background required to become a Rotary Kiln Operator?

While formal education requirements may vary, many Rotary Kiln Operators hold a degree in Chemical Engineering or a related field.

What are the career prospects for a Rotary Kiln Operator?

Experienced Rotary Kiln Operators can advance to supervisory or management roles within the cement manufacturing industry, or pursue specialized roles in kiln optimization or process engineering.

What are the safety considerations for Rotary Kiln Operators?

Rotary Kiln Operators must adhere to strict safety protocols, as they work with high temperatures, heavy machinery, and potentially hazardous materials.

What is the work environment of a Rotary Kiln Operator?

Rotary Kiln Operators typically work in industrial settings, operating kilns and monitoring processes in a production facility.

What are the key challenges faced by Rotary Kiln Operators?

Challenges may include maintaining optimal kiln performance, troubleshooting equipment malfunctions, and ensuring product quality while adhering to safety regulations.