Are you a seasoned Rotor Casting Machine Setup Operator seeking a new career path? Discover our professionally built Rotor Casting Machine Setup Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

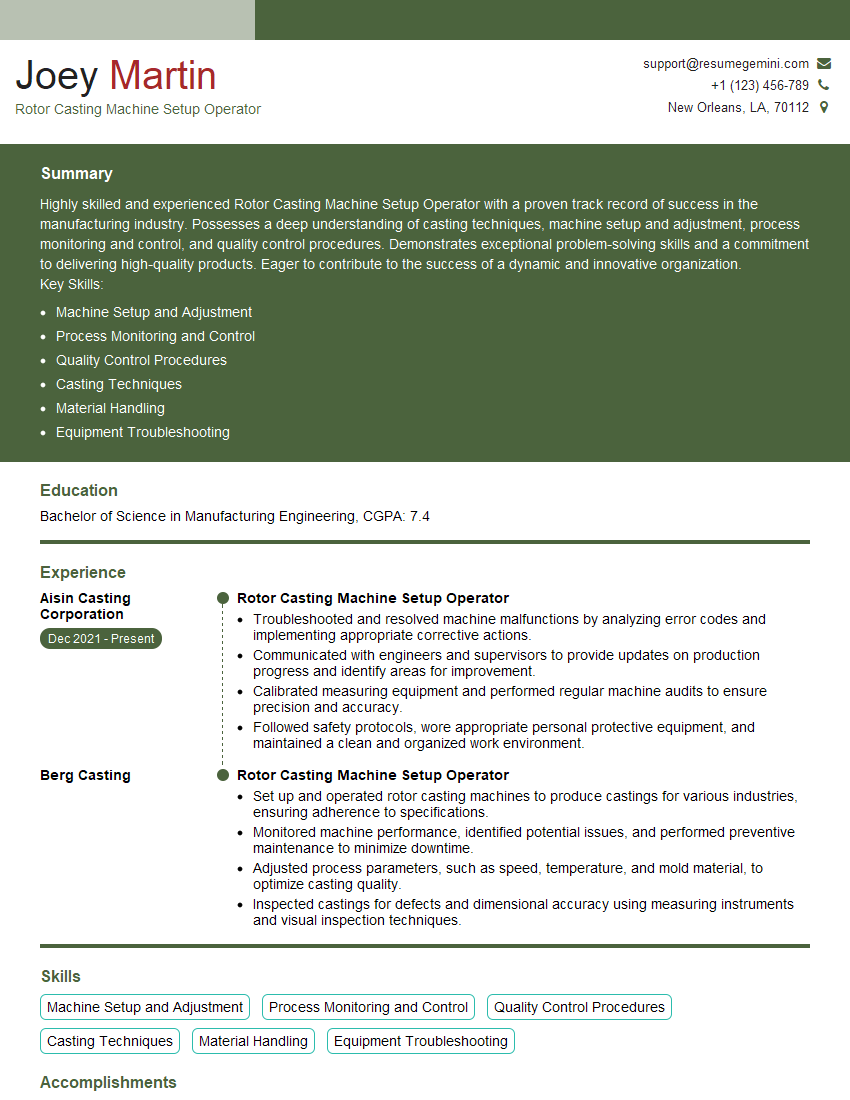

Joey Martin

Rotor Casting Machine Setup Operator

Summary

Highly skilled and experienced Rotor Casting Machine Setup Operator with a proven track record of success in the manufacturing industry. Possesses a deep understanding of casting techniques, machine setup and adjustment, process monitoring and control, and quality control procedures. Demonstrates exceptional problem-solving skills and a commitment to delivering high-quality products. Eager to contribute to the success of a dynamic and innovative organization.

Key Skills:

- Machine Setup and Adjustment

- Process Monitoring and Control

- Quality Control Procedures

- Casting Techniques

- Material Handling

- Equipment Troubleshooting

Education

Bachelor of Science in Manufacturing Engineering

November 2017

Skills

- Machine Setup and Adjustment

- Process Monitoring and Control

- Quality Control Procedures

- Casting Techniques

- Material Handling

- Equipment Troubleshooting

Work Experience

Rotor Casting Machine Setup Operator

- Troubleshooted and resolved machine malfunctions by analyzing error codes and implementing appropriate corrective actions.

- Communicated with engineers and supervisors to provide updates on production progress and identify areas for improvement.

- Calibrated measuring equipment and performed regular machine audits to ensure precision and accuracy.

- Followed safety protocols, wore appropriate personal protective equipment, and maintained a clean and organized work environment.

Rotor Casting Machine Setup Operator

- Set up and operated rotor casting machines to produce castings for various industries, ensuring adherence to specifications.

- Monitored machine performance, identified potential issues, and performed preventive maintenance to minimize downtime.

- Adjusted process parameters, such as speed, temperature, and mold material, to optimize casting quality.

- Inspected castings for defects and dimensional accuracy using measuring instruments and visual inspection techniques.

Accomplishments

- Successfully implemented new setup procedures, reducing machine downtime by 20% and increasing production capacity by 15%

- Optimized casting parameters to achieve a defect rate below 1%, exceeding industry standards

- Led a team to develop and implement a predictive maintenance program for critical rotor casting equipment, resulting in a 30% reduction in unplanned downtime

- Trained and mentored junior operators, effectively enhancing their skills and ensuring continuous improvement in setup accuracy and efficiency

- Analyzed production data and implemented targeted adjustments to machine parameters, improving rotor quality by 10%

Awards

- Industry Recognition Award for Exceptional Rotor Casting Machine Setup Efficiency

- Award of Excellence for Innovation in Rotor Casting Machine Setup and Operation

- Recognition for Proficiency in Rotor Casting Machine Setup and Optimization Techniques

- Award for Outstanding Performance in Rotor Casting Machine Setup and Control

Certificates

- Certified Rotor Casting Machine Operator

- Certified Quality Control Technician

- OSHA Safety Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rotor Casting Machine Setup Operator

- Highlight your technical skills and experience in machine setup, process monitoring, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, emphasizing the skills and experience most relevant to the position.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting.

Essential Experience Highlights for a Strong Rotor Casting Machine Setup Operator Resume

- Set up and adjust rotor casting machines according to specifications, ensuring optimal performance and efficiency.

- Monitor and control casting processes, including temperature, pressure, and casting speed, to ensure product quality.

- Implement quality control procedures to identify and correct defects, maintaining high standards and meeting customer requirements.

- Troubleshoot and resolve equipment malfunctions, ensuring minimal downtime and maintaining production schedules.

- Handle and transport materials safely, following established procedures and ensuring a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Rotor Casting Machine Setup Operator

What is the primary responsibility of a Rotor Casting Machine Setup Operator?

The primary responsibility of a Rotor Casting Machine Setup Operator is to ensure that the casting machine is properly set up and adjusted, and that the casting process is monitored and controlled to produce high-quality products.

What are the key skills required for a successful Rotor Casting Machine Setup Operator?

The key skills required for a successful Rotor Casting Machine Setup Operator include machine setup and adjustment, process monitoring and control, quality control procedures, casting techniques, material handling, and equipment troubleshooting.

What is the typical work environment for a Rotor Casting Machine Setup Operator?

Rotor Casting Machine Setup Operators typically work in a manufacturing environment, in close proximity to casting machines and other equipment. They may be required to work in a variety of conditions, including heat, noise, and fumes.

What are the career prospects for a Rotor Casting Machine Setup Operator?

Rotor Casting Machine Setup Operators can advance their careers by developing their skills and experience. They may be promoted to lead operator, supervisor, or manager positions. With additional training and education, they may also move into related fields, such as quality control or engineering.

What is the average salary for a Rotor Casting Machine Setup Operator?

The average salary for a Rotor Casting Machine Setup Operator varies depending on experience, location, and industry. However, according to recent data, the average salary for a Rotor Casting Machine Setup Operator in the United States is around $50,000 per year.