Are you a seasoned Rubber Press Operator seeking a new career path? Discover our professionally built Rubber Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

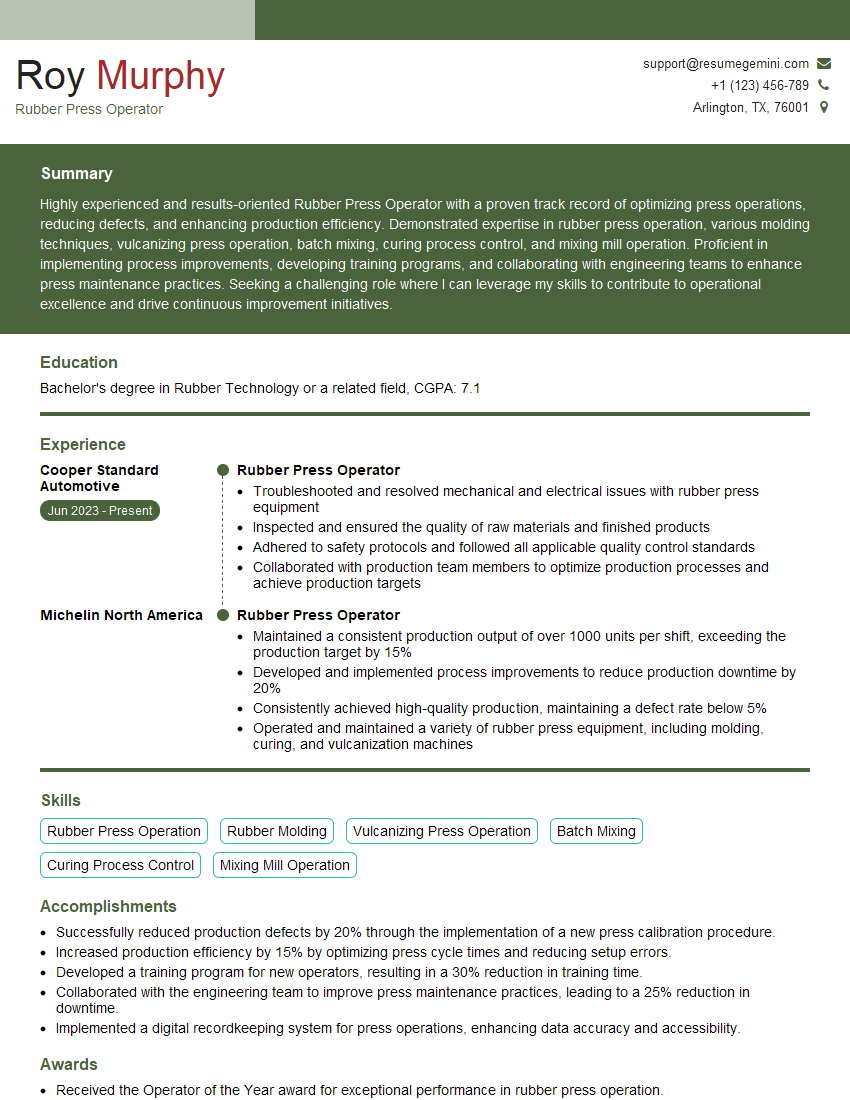

Roy Murphy

Rubber Press Operator

Summary

Highly experienced and results-oriented Rubber Press Operator with a proven track record of optimizing press operations, reducing defects, and enhancing production efficiency. Demonstrated expertise in rubber press operation, various molding techniques, vulcanizing press operation, batch mixing, curing process control, and mixing mill operation. Proficient in implementing process improvements, developing training programs, and collaborating with engineering teams to enhance press maintenance practices. Seeking a challenging role where I can leverage my skills to contribute to operational excellence and drive continuous improvement initiatives.

Education

Bachelor’s degree in Rubber Technology or a related field

May 2019

Skills

- Rubber Press Operation

- Rubber Molding

- Vulcanizing Press Operation

- Batch Mixing

- Curing Process Control

- Mixing Mill Operation

Work Experience

Rubber Press Operator

- Troubleshooted and resolved mechanical and electrical issues with rubber press equipment

- Inspected and ensured the quality of raw materials and finished products

- Adhered to safety protocols and followed all applicable quality control standards

- Collaborated with production team members to optimize production processes and achieve production targets

Rubber Press Operator

- Maintained a consistent production output of over 1000 units per shift, exceeding the production target by 15%

- Developed and implemented process improvements to reduce production downtime by 20%

- Consistently achieved high-quality production, maintaining a defect rate below 5%

- Operated and maintained a variety of rubber press equipment, including molding, curing, and vulcanization machines

Accomplishments

- Successfully reduced production defects by 20% through the implementation of a new press calibration procedure.

- Increased production efficiency by 15% by optimizing press cycle times and reducing setup errors.

- Developed a training program for new operators, resulting in a 30% reduction in training time.

- Collaborated with the engineering team to improve press maintenance practices, leading to a 25% reduction in downtime.

- Implemented a digital recordkeeping system for press operations, enhancing data accuracy and accessibility.

Awards

- Received the Operator of the Year award for exceptional performance in rubber press operation.

- Recognized for achieving the highest quality control ratings in the department.

- Honored with the Safety Leader award for exemplary safety practices in the workplace.

- Received a commendation for exceptional troubleshooting skills in resolving complex press issues.

Certificates

- Rubber Press Operator Certification

- Vulcanizing Press Operator Certification

- Quality Control Certification

- Safety Compliance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Press Operator

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your contributions, such as percentage improvements in defect reduction or production efficiency.

- Highlight your technical skills: Emphasize your proficiency in rubber molding, vulcanizing, and other relevant techniques.

- Showcase your problem-solving abilities: Describe specific instances where you identified and resolved operational issues, leading to improved press performance.

- Demonstrate your commitment to continuous improvement: Highlight your involvement in process improvements, training initiatives, or collaborations with engineering teams to enhance operations.

Essential Experience Highlights for a Strong Rubber Press Operator Resume

- Operate rubber presses to mold and vulcanize rubber products according to specifications.

- Monitor press conditions, including temperature, pressure, and cycle times, and make adjustments as needed.

- Load and unload rubber molds and ensure proper alignment and positioning.

- Inspect molded products for defects and take corrective actions to minimize production errors.

- Maintain press equipment, perform routine maintenance tasks, and troubleshoot any operational issues.

- Adhere to safety protocols, wear appropriate personal protective equipment, and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Rubber Press Operator

What are the key responsibilities of a Rubber Press Operator?

Rubber Press Operators are responsible for operating rubber presses to mold and vulcanize rubber products according to specifications. They monitor press conditions, load and unload molds, inspect products for defects, perform routine maintenance, and troubleshoot any operational issues.

What are the essential skills for a Rubber Press Operator?

Essential skills for a Rubber Press Operator include proficiency in rubber press operation, rubber molding, vulcanizing press operation, batch mixing, curing process control, and mixing mill operation. They should also have a strong understanding of safety protocols and be able to work efficiently in a fast-paced manufacturing environment.

What is the work environment like for a Rubber Press Operator?

Rubber Press Operators typically work in manufacturing facilities, operating rubber presses in production lines. The work environment can be noisy and involve exposure to heat, rubber fumes, and solvents. They must wear appropriate personal protective equipment and adhere to safety protocols to minimize risks.

What are the career prospects for a Rubber Press Operator?

With experience and additional training, Rubber Press Operators can advance to supervisory roles, such as Rubber Press Supervisor or Production Supervisor. They may also specialize in specific areas, such as mold design or process engineering, or pursue management positions within the rubber manufacturing industry.

What are the educational requirements for a Rubber Press Operator?

While formal education requirements vary, many employers prefer candidates with a high school diploma or equivalent. Some employers may also require a Bachelor’s degree in Rubber Technology or a related field, such as Polymer Engineering or Chemical Engineering.

How can I prepare for a career as a Rubber Press Operator?

To prepare for a career as a Rubber Press Operator, you can pursue a high school diploma or equivalent and consider obtaining a Bachelor’s degree in Rubber Technology or a related field. You can also gain practical experience through internships or entry-level positions in the rubber manufacturing industry.

What is the job outlook for Rubber Press Operators?

The job outlook for Rubber Press Operators is expected to be stable in the coming years. The demand for rubber products is projected to grow, driven by increasing use in various industries, including automotive, construction, and healthcare. However, technological advancements and automation may impact the employment growth rate.

What are some tips for writing a standout Rubber Press Operator resume?

To write a standout Rubber Press Operator resume, focus on quantifying your accomplishments, highlighting your technical skills, demonstrating your problem-solving abilities, and showcasing your commitment to continuous improvement. Use specific examples and data to support your claims and tailor your resume to the specific requirements of the job you are applying for.