Are you a seasoned Rubber Vulcanizing Machine Operator seeking a new career path? Discover our professionally built Rubber Vulcanizing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

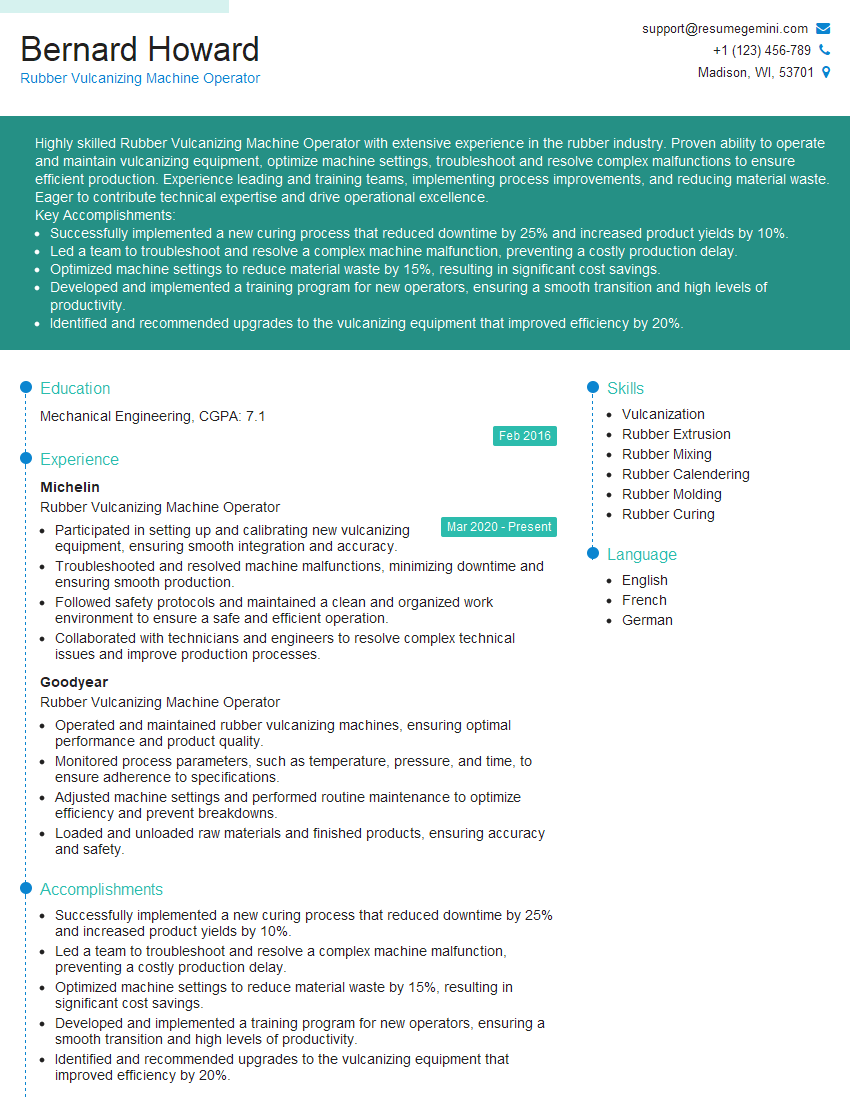

Bernard Howard

Rubber Vulcanizing Machine Operator

Summary

Highly skilled Rubber Vulcanizing Machine Operator with extensive experience in the rubber industry. Proven ability to operate and maintain vulcanizing equipment, optimize machine settings, troubleshoot and resolve complex malfunctions to ensure efficient production. Experience leading and training teams, implementing process improvements, and reducing material waste. Eager to contribute technical expertise and drive operational excellence.

Key Accomplishments:

- Successfully implemented a new curing process that reduced downtime by 25% and increased product yields by 10%.

- Led a team to troubleshoot and resolve a complex machine malfunction, preventing a costly production delay.

- Optimized machine settings to reduce material waste by 15%, resulting in significant cost savings.

- Developed and implemented a training program for new operators, ensuring a smooth transition and high levels of productivity.

- Identified and recommended upgrades to the vulcanizing equipment that improved efficiency by 20%.

Education

Mechanical Engineering

February 2016

Skills

- Vulcanization

- Rubber Extrusion

- Rubber Mixing

- Rubber Calendering

- Rubber Molding

- Rubber Curing

Work Experience

Rubber Vulcanizing Machine Operator

- Participated in setting up and calibrating new vulcanizing equipment, ensuring smooth integration and accuracy.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and ensuring smooth production.

- Followed safety protocols and maintained a clean and organized work environment to ensure a safe and efficient operation.

- Collaborated with technicians and engineers to resolve complex technical issues and improve production processes.

Rubber Vulcanizing Machine Operator

- Operated and maintained rubber vulcanizing machines, ensuring optimal performance and product quality.

- Monitored process parameters, such as temperature, pressure, and time, to ensure adherence to specifications.

- Adjusted machine settings and performed routine maintenance to optimize efficiency and prevent breakdowns.

- Loaded and unloaded raw materials and finished products, ensuring accuracy and safety.

Accomplishments

- Successfully implemented a new curing process that reduced downtime by 25% and increased product yields by 10%.

- Led a team to troubleshoot and resolve a complex machine malfunction, preventing a costly production delay.

- Optimized machine settings to reduce material waste by 15%, resulting in significant cost savings.

- Developed and implemented a training program for new operators, ensuring a smooth transition and high levels of productivity.

- Identified and recommended upgrades to the vulcanizing equipment that improved efficiency by 20%.

Awards

- Received Operator of the Year award for consistently exceeding production targets and maintaining a high level of quality.

- Recognized with a Safety Star award for maintaining an exemplary safety record on the production floor.

- Received a Top Performer award for consistently exceeding performance expectations and demonstrating a strong work ethic.

- Honored with a Quality Champion award for consistently producing highquality vulcanized products that meet or exceed customer specifications.

Certificates

- Certified Rubber Vulcanizing Machine Operator

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- ASME Boiler and Pressure Vessel Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber Vulcanizing Machine Operator

- Highlight your technical skills and experience in operating and maintaining vulcanizing equipment.

- Quantify your accomplishments with specific metrics to demonstrate your impact on productivity and efficiency.

- Showcase your problem-solving abilities by providing examples of how you resolved complex machine malfunctions.

- Emphasize your commitment to safety and quality by mentioning your adherence to industry standards and best practices.

Essential Experience Highlights for a Strong Rubber Vulcanizing Machine Operator Resume

- Operate and maintain rubber vulcanizing equipment to produce high-quality products.

- Monitor and control vulcanization process parameters, such as temperature, pressure, and curing time.

- Troubleshoot and resolve machine malfunctions, ensuring minimal downtime and efficient production.

- Implement process improvements to enhance productivity and reduce waste.

- Train and supervise new operators to maintain high standards of operation.

- Maintain a clean and organized work area, adhering to safety regulations.

- Work effectively as part of a team to achieve production goals.

Frequently Asked Questions (FAQ’s) For Rubber Vulcanizing Machine Operator

What are the key skills required for a Rubber Vulcanizing Machine Operator?

Key skills for a Rubber Vulcanizing Machine Operator include: expertise in vulcanization processes, rubber extrusion, rubber mixing, rubber calendering, rubber molding, and rubber curing. Additionally, strong mechanical aptitude and troubleshooting skills are essential for maintaining and repairing vulcanizing equipment.

What are the career prospects for a Rubber Vulcanizing Machine Operator?

With experience and additional training, Rubber Vulcanizing Machine Operators can advance to roles such as Production Supervisor, Maintenance Technician, or Quality Control Inspector. Those with entrepreneurial aspirations may also consider starting their own rubber manufacturing business.

How do I become a certified Rubber Vulcanizing Machine Operator?

There are several organizations that offer certification programs for Rubber Vulcanizing Machine Operators. These programs typically include classroom instruction and hands-on training, and successful completion may lead to industry-recognized certification.

What is the work environment like for a Rubber Vulcanizing Machine Operator?

Rubber Vulcanizing Machine Operators typically work in manufacturing facilities, operating vulcanizing equipment in a production environment. The work can be repetitive and physically demanding, but it also offers opportunities for skill development and career advancement.

What are the safety precautions that Rubber Vulcanizing Machine Operators must follow?

Rubber Vulcanizing Machine Operators must adhere to strict safety protocols to minimize risks associated with working with heavy machinery and hazardous materials. These precautions include wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.

What is the average salary for a Rubber Vulcanizing Machine Operator?

According to Indeed, the average salary for a Rubber Vulcanizing Machine Operator in the United States is around $45,000 per year. However, salaries may vary depending on factors such as experience, location, and industry.

What are the job outlook prospects for Rubber Vulcanizing Machine Operators?

The job outlook for Rubber Vulcanizing Machine Operators is expected to be stable in the coming years. The demand for rubber products is expected to remain steady, and there will be a need for skilled operators to operate and maintain vulcanizing equipment.