Are you a seasoned Rum Processing Operator seeking a new career path? Discover our professionally built Rum Processing Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

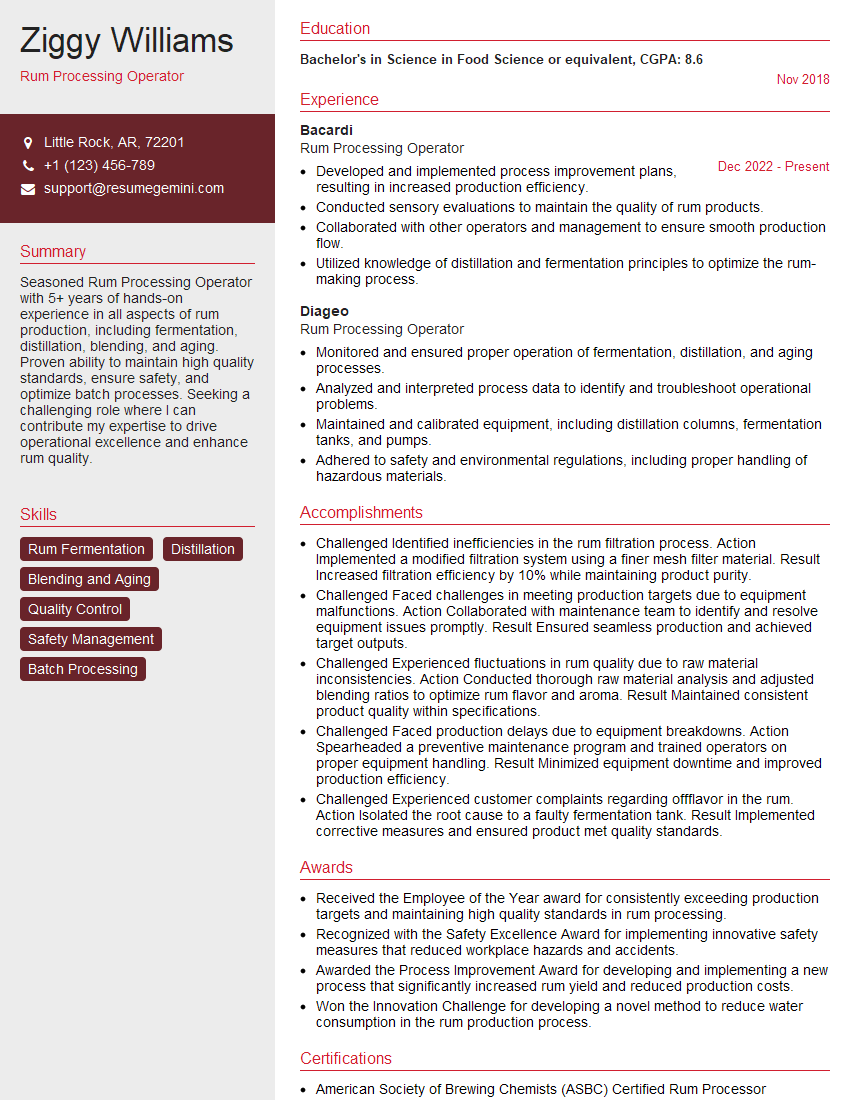

Ziggy Williams

Rum Processing Operator

Summary

Seasoned Rum Processing Operator with 5+ years of hands-on experience in all aspects of rum production, including fermentation, distillation, blending, and aging. Proven ability to maintain high quality standards, ensure safety, and optimize batch processes. Seeking a challenging role where I can contribute my expertise to drive operational excellence and enhance rum quality.

Education

Bachelor’s in Science in Food Science or equivalent

November 2018

Skills

- Rum Fermentation

- Distillation

- Blending and Aging

- Quality Control

- Safety Management

- Batch Processing

Work Experience

Rum Processing Operator

- Developed and implemented process improvement plans, resulting in increased production efficiency.

- Conducted sensory evaluations to maintain the quality of rum products.

- Collaborated with other operators and management to ensure smooth production flow.

- Utilized knowledge of distillation and fermentation principles to optimize the rum-making process.

Rum Processing Operator

- Monitored and ensured proper operation of fermentation, distillation, and aging processes.

- Analyzed and interpreted process data to identify and troubleshoot operational problems.

- Maintained and calibrated equipment, including distillation columns, fermentation tanks, and pumps.

- Adhered to safety and environmental regulations, including proper handling of hazardous materials.

Accomplishments

- Challenged Identified inefficiencies in the rum filtration process. Action Implemented a modified filtration system using a finer mesh filter material. Result Increased filtration efficiency by 10% while maintaining product purity.

- Challenged Faced challenges in meeting production targets due to equipment malfunctions. Action Collaborated with maintenance team to identify and resolve equipment issues promptly. Result Ensured seamless production and achieved target outputs.

- Challenged Experienced fluctuations in rum quality due to raw material inconsistencies. Action Conducted thorough raw material analysis and adjusted blending ratios to optimize rum flavor and aroma. Result Maintained consistent product quality within specifications.

- Challenged Faced production delays due to equipment breakdowns. Action Spearheaded a preventive maintenance program and trained operators on proper equipment handling. Result Minimized equipment downtime and improved production efficiency.

- Challenged Experienced customer complaints regarding offflavor in the rum. Action Isolated the root cause to a faulty fermentation tank. Result Implemented corrective measures and ensured product met quality standards.

Awards

- Received the Employee of the Year award for consistently exceeding production targets and maintaining high quality standards in rum processing.

- Recognized with the Safety Excellence Award for implementing innovative safety measures that reduced workplace hazards and accidents.

- Awarded the Process Improvement Award for developing and implementing a new process that significantly increased rum yield and reduced production costs.

- Won the Innovation Challenge for developing a novel method to reduce water consumption in the rum production process.

Certificates

- American Society of Brewing Chemists (ASBC) Certified Rum Processor

- Rum Producers Association Certified Rum Production Specialist

- Institute of Food Technologists (IFT) Certified Food Scientist

- Occupational Safety and Health Administration (OSHA) Hazardous Materials Handling

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rum Processing Operator

- Highlight your technical expertise in rum processing techniques, including fermentation, distillation, blending, and aging.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact on production efficiency, quality improvement, or cost optimization.

- Showcase your knowledge of rum production regulations and industry best practices, emphasizing your commitment to safety and quality.

- Include keywords relevant to the rum processing industry, such as ‘distillation,’ ‘fermentation,’ ‘blending,’ and ‘aging,’ to enhance your resume’s visibility to potential employers.

Essential Experience Highlights for a Strong Rum Processing Operator Resume

- Monitor and control fermentation processes to ensure optimal yeast activity and sugar conversion.

- Operate distillation equipment to separate alcohol from fermented wash, controlling temperature, pressure, and reflux ratios.

- Blend different rum distillates to create unique flavor profiles and meet customer specifications.

- Manage rum aging process, including barrel selection, temperature control, and periodic tastings.

- Conduct quality control tests to ensure adherence to established standards and regulatory requirements.

- Implement and maintain safety protocols, including hazardous material handling, equipment operation, and emergency procedures.

- Supervise and train production staff, ensuring adherence to best practices and safety regulations.

Frequently Asked Questions (FAQ’s) For Rum Processing Operator

What is the role of a Rum Processing Operator?

A Rum Processing Operator is responsible for overseeing the production of rum, from fermentation and distillation to blending, aging, and quality control.

What are the key skills required for a Rum Processing Operator?

Key skills include knowledge of rum fermentation, distillation, blending, and aging processes, as well as quality control, safety management, and batch processing techniques.

What are the career prospects for a Rum Processing Operator?

With experience and additional qualifications, Rum Processing Operators can advance to roles such as Production Supervisor, Distillery Manager, or Quality Assurance Manager.

What are the educational requirements for a Rum Processing Operator?

While educational requirements may vary, many Rum Processing Operators hold a Bachelor’s degree in Science in Food Science or a related field.

What is the work environment like for a Rum Processing Operator?

Rum Processing Operators typically work in a production facility, which may involve working with machinery, handling hazardous materials, and adhering to safety protocols.

What are the certifications available for Rum Processing Operators?

Relevant certifications include the ServSafe Food Safety Manager Certification and the American Society for Quality (ASQ) Certified Quality Inspector (CQI) certification.

What are the top companies that hire Rum Processing Operators?

Top companies that hire Rum Processing Operators include Bacardi, Diageo, and Pernod Ricard.