Are you a seasoned Sand Molder seeking a new career path? Discover our professionally built Sand Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

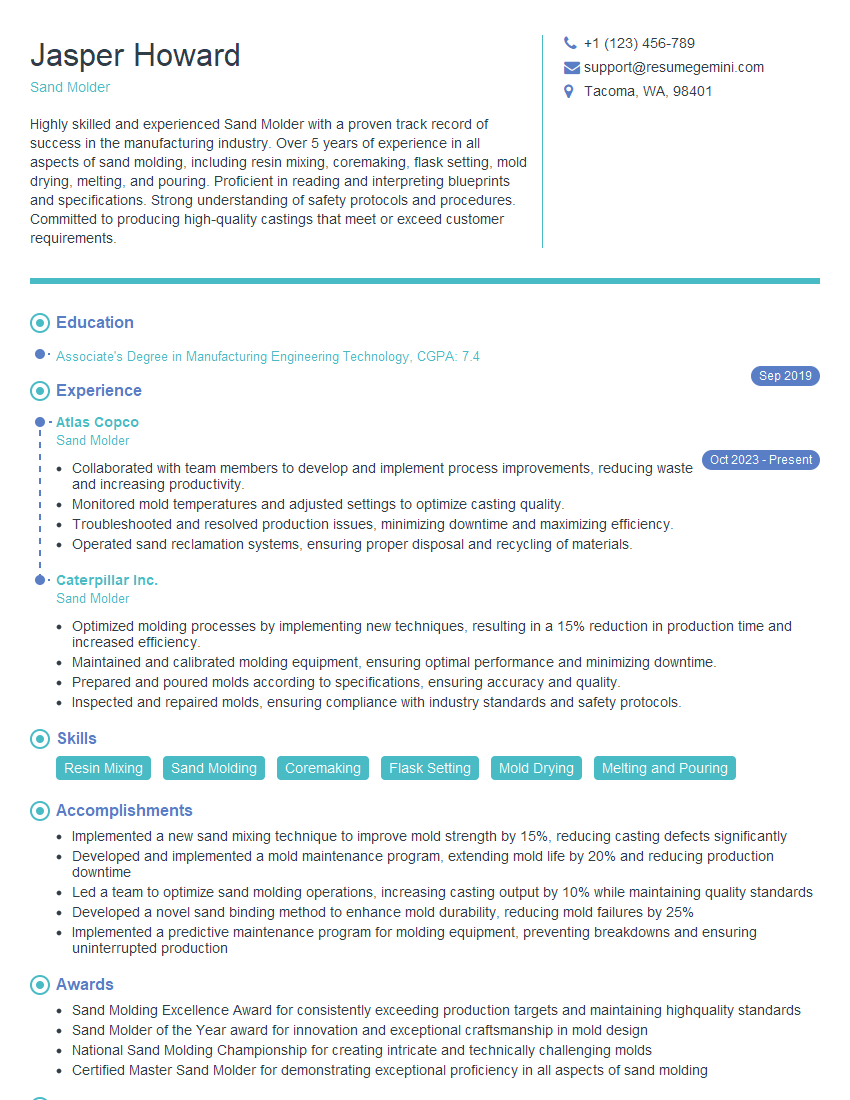

Jasper Howard

Sand Molder

Summary

Highly skilled and experienced Sand Molder with a proven track record of success in the manufacturing industry. Over 5 years of experience in all aspects of sand molding, including resin mixing, coremaking, flask setting, mold drying, melting, and pouring. Proficient in reading and interpreting blueprints and specifications. Strong understanding of safety protocols and procedures. Committed to producing high-quality castings that meet or exceed customer requirements.

Education

Associate’s Degree in Manufacturing Engineering Technology

September 2019

Skills

- Resin Mixing

- Sand Molding

- Coremaking

- Flask Setting

- Mold Drying

- Melting and Pouring

Work Experience

Sand Molder

- Collaborated with team members to develop and implement process improvements, reducing waste and increasing productivity.

- Monitored mold temperatures and adjusted settings to optimize casting quality.

- Troubleshooted and resolved production issues, minimizing downtime and maximizing efficiency.

- Operated sand reclamation systems, ensuring proper disposal and recycling of materials.

Sand Molder

- Optimized molding processes by implementing new techniques, resulting in a 15% reduction in production time and increased efficiency.

- Maintained and calibrated molding equipment, ensuring optimal performance and minimizing downtime.

- Prepared and poured molds according to specifications, ensuring accuracy and quality.

- Inspected and repaired molds, ensuring compliance with industry standards and safety protocols.

Accomplishments

- Implemented a new sand mixing technique to improve mold strength by 15%, reducing casting defects significantly

- Developed and implemented a mold maintenance program, extending mold life by 20% and reducing production downtime

- Led a team to optimize sand molding operations, increasing casting output by 10% while maintaining quality standards

- Developed a novel sand binding method to enhance mold durability, reducing mold failures by 25%

- Implemented a predictive maintenance program for molding equipment, preventing breakdowns and ensuring uninterrupted production

Awards

- Sand Molding Excellence Award for consistently exceeding production targets and maintaining highquality standards

- Sand Molder of the Year award for innovation and exceptional craftsmanship in mold design

- National Sand Molding Championship for creating intricate and technically challenging molds

- Certified Master Sand Molder for demonstrating exceptional proficiency in all aspects of sand molding

Certificates

- Certified Sand Molder

- OSH 10-Hour Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sand Molder

- Highlight your experience in sand molding, including specific techniques and equipment you have used.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Sand Molder Resume

- Mix and prepare resin according to specifications

- Construct and assemble molds using sand, binders, and other materials

- Create and insert cores into molds to form internal cavities

- Set flasks and position patterns to create mold cavities

- Dry molds to remove moisture and prepare for pouring

- Operate melting furnaces and pour molten metal into molds

- Monitor and control casting process to ensure quality and efficiency

Frequently Asked Questions (FAQ’s) For Sand Molder

What is the primary role of a Sand Molder?

The primary role of a Sand Molder is to create molds used in the metal casting process. They use sand, binders, and other materials to form the molds, which are then filled with molten metal to create castings.

What are the key skills required for Sand Molders?

Key skills for Sand Molders include: reading and interpreting blueprints and specifications, mixing and preparing resin, constructing and assembling molds, creating and inserting cores, setting flasks and positioning patterns, drying molds, operating melting furnaces, and pouring molten metal.

What are the educational requirements for Sand Molders?

Educational requirements for Sand Molders typically include a high school diploma or equivalent, although some employers may prefer candidates with an Associate’s Degree in Manufacturing Engineering Technology or a related field.

What is the job outlook for Sand Molders?

The job outlook for Sand Molders is expected to grow slightly over the next few years. This growth is expected to be driven by the increasing demand for castings in various industries, such as automotive, aerospace, and construction.

What are the typical working conditions for Sand Molders?

Sand Molders typically work in foundries, which can be hot, noisy, and dusty. They may also be required to work overtime to meet production deadlines.

What are the safety concerns for Sand Molders?

Sand Molders should be aware of the potential hazards associated with their work, such as exposure to molten metal, hazardous chemicals, and dust. They should also be properly trained in the use of safety equipment, such as respirators, gloves, and protective clothing.