Are you a seasoned Saw Maker seeking a new career path? Discover our professionally built Saw Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

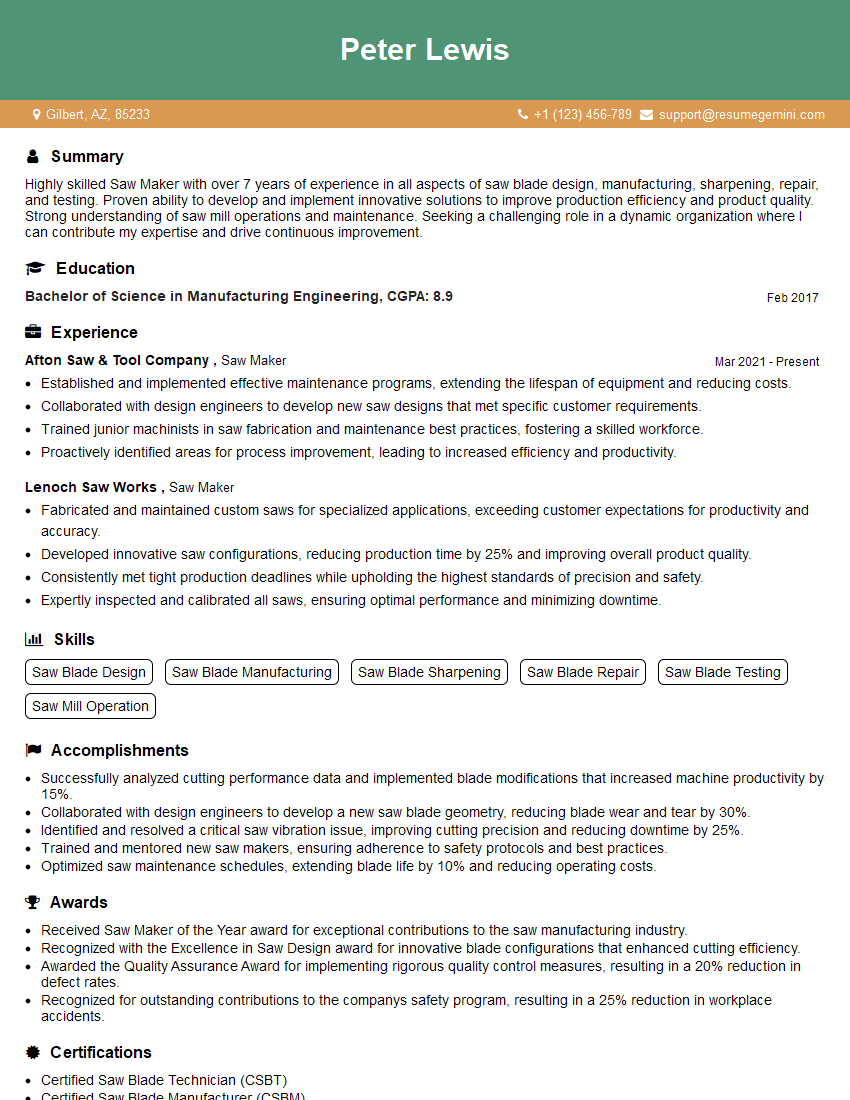

Peter Lewis

Saw Maker

Summary

Highly skilled Saw Maker with over 7 years of experience in all aspects of saw blade design, manufacturing, sharpening, repair, and testing. Proven ability to develop and implement innovative solutions to improve production efficiency and product quality. Strong understanding of saw mill operations and maintenance. Seeking a challenging role in a dynamic organization where I can contribute my expertise and drive continuous improvement.

Education

Bachelor of Science in Manufacturing Engineering

February 2017

Skills

- Saw Blade Design

- Saw Blade Manufacturing

- Saw Blade Sharpening

- Saw Blade Repair

- Saw Blade Testing

- Saw Mill Operation

Work Experience

Saw Maker

- Established and implemented effective maintenance programs, extending the lifespan of equipment and reducing costs.

- Collaborated with design engineers to develop new saw designs that met specific customer requirements.

- Trained junior machinists in saw fabrication and maintenance best practices, fostering a skilled workforce.

- Proactively identified areas for process improvement, leading to increased efficiency and productivity.

Saw Maker

- Fabricated and maintained custom saws for specialized applications, exceeding customer expectations for productivity and accuracy.

- Developed innovative saw configurations, reducing production time by 25% and improving overall product quality.

- Consistently met tight production deadlines while upholding the highest standards of precision and safety.

- Expertly inspected and calibrated all saws, ensuring optimal performance and minimizing downtime.

Accomplishments

- Successfully analyzed cutting performance data and implemented blade modifications that increased machine productivity by 15%.

- Collaborated with design engineers to develop a new saw blade geometry, reducing blade wear and tear by 30%.

- Identified and resolved a critical saw vibration issue, improving cutting precision and reducing downtime by 25%.

- Trained and mentored new saw makers, ensuring adherence to safety protocols and best practices.

- Optimized saw maintenance schedules, extending blade life by 10% and reducing operating costs.

Awards

- Received Saw Maker of the Year award for exceptional contributions to the saw manufacturing industry.

- Recognized with the Excellence in Saw Design award for innovative blade configurations that enhanced cutting efficiency.

- Awarded the Quality Assurance Award for implementing rigorous quality control measures, resulting in a 20% reduction in defect rates.

- Recognized for outstanding contributions to the companys safety program, resulting in a 25% reduction in workplace accidents.

Certificates

- Certified Saw Blade Technician (CSBT)

- Certified Saw Blade Manufacturer (CSBM)

- Certified Saw Blade Inspector (CSBI)

- Certified Saw Mill Operator (CSMO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Saw Maker

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your skills and experience in saw blade design and manufacturing.

- Showcase your understanding of saw mill operations and maintenance.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to each specific job you apply for.

Essential Experience Highlights for a Strong Saw Maker Resume

- Designed and developed saw blades for various applications, including woodworking, metalworking, and construction.

- Managed all aspects of saw blade manufacturing, from raw material procurement to finished product inspection.

- Established and implemented quality control procedures to ensure that all saw blades met or exceeded industry standards.

- Provided technical support to customers and assisted in troubleshooting saw blade issues.

- Conducted training sessions on saw blade maintenance and safety.

- Collaborated with engineers and production staff to optimize saw mill operations.

Frequently Asked Questions (FAQ’s) For Saw Maker

What are the key skills required to be a successful Saw Maker?

The key skills required to be a successful Saw Maker include saw blade design, manufacturing, sharpening, repair, testing, and saw mill operation.

What are the educational requirements to become a Saw Maker?

The educational requirements to become a Saw Maker typically include a high school diploma or equivalent, with some employers preferring candidates with a bachelor’s degree in manufacturing engineering or a related field.

What are the career prospects for Saw Makers?

The career prospects for Saw Makers are generally good, with employment opportunities expected to grow in the coming years due to increasing demand for saw blades in various industries.

What is the average salary for Saw Makers?

The average salary for Saw Makers varies depending on experience, location, and employer, but typically ranges between $40,000 and $60,000 per year.

What are the working conditions like for Saw Makers?

Saw Makers typically work in manufacturing facilities, which can be noisy and dusty. They may also work outdoors in saw mills or other locations where saw blades are used.

What are the safety hazards associated with being a Saw Maker?

The safety hazards associated with being a Saw Maker include exposure to sharp objects, rotating machinery, and hazardous chemicals. Saw Makers must follow all safety protocols and wear appropriate personal protective equipment.