Are you a seasoned Screw Cutter seeking a new career path? Discover our professionally built Screw Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

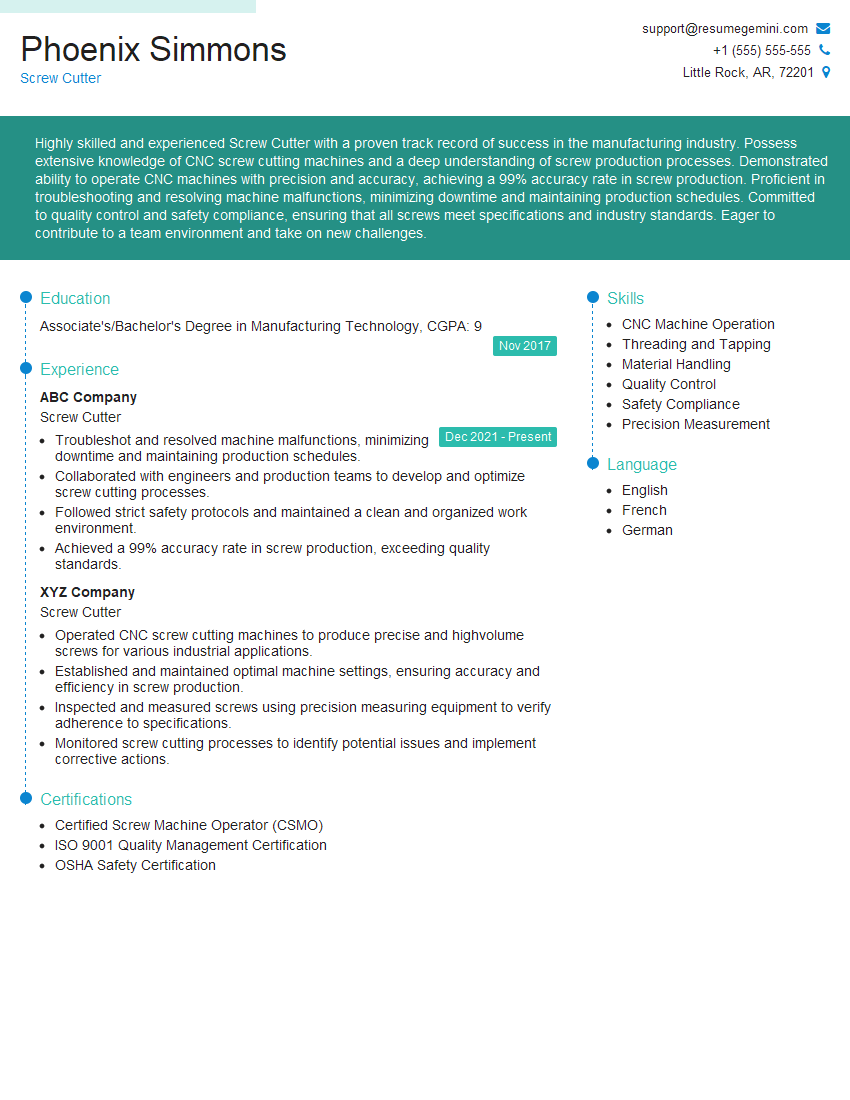

Phoenix Simmons

Screw Cutter

Summary

Highly skilled and experienced Screw Cutter with a proven track record of success in the manufacturing industry. Possess extensive knowledge of CNC screw cutting machines and a deep understanding of screw production processes. Demonstrated ability to operate CNC machines with precision and accuracy, achieving a 99% accuracy rate in screw production. Proficient in troubleshooting and resolving machine malfunctions, minimizing downtime and maintaining production schedules. Committed to quality control and safety compliance, ensuring that all screws meet specifications and industry standards. Eager to contribute to a team environment and take on new challenges.

Education

Associate’s/Bachelor’s Degree in Manufacturing Technology

November 2017

Skills

- CNC Machine Operation

- Threading and Tapping

- Material Handling

- Quality Control

- Safety Compliance

- Precision Measurement

Work Experience

Screw Cutter

- Troubleshot and resolved machine malfunctions, minimizing downtime and maintaining production schedules.

- Collaborated with engineers and production teams to develop and optimize screw cutting processes.

- Followed strict safety protocols and maintained a clean and organized work environment.

- Achieved a 99% accuracy rate in screw production, exceeding quality standards.

Screw Cutter

- Operated CNC screw cutting machines to produce precise and highvolume screws for various industrial applications.

- Established and maintained optimal machine settings, ensuring accuracy and efficiency in screw production.

- Inspected and measured screws using precision measuring equipment to verify adherence to specifications.

- Monitored screw cutting processes to identify potential issues and implement corrective actions.

Certificates

- Certified Screw Machine Operator (CSMO)

- ISO 9001 Quality Management Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Screw Cutter

- Highlight your technical skills and experience in CNC screw cutting operations.

- Quantify your accomplishments and provide specific examples of your contributions to the manufacturing process.

- Demonstrate your knowledge of quality control procedures and safety protocols.

- Showcase your problem-solving and troubleshooting abilities by providing examples of how you resolved machine malfunctions.

Essential Experience Highlights for a Strong Screw Cutter Resume

- Operate CNC screw cutting machines to produce precise and high-volume screws for various industrial applications.

- Establish and maintain optimal machine settings, ensuring accuracy and efficiency in screw production.

- Inspect and measure screws using precision measuring equipment to verify adherence to specifications.

- Monitor screw cutting processes to identify potential issues and implement corrective actions.

- Troubleshoot and resolve machine malfunctions, minimizing downtime and maintaining production schedules.

- Collaborate with engineers and production teams to develop and optimize screw cutting processes.

- Follow strict safety protocols and maintain a clean and organized work environment.

Frequently Asked Questions (FAQ’s) For Screw Cutter

What is the role of a Screw Cutter?

A Screw Cutter operates CNC screw cutting machines to produce precise and high-volume screws for various industrial applications. They are responsible for establishing and maintaining optimal machine settings, inspecting and measuring screws to ensure they meet specifications, monitoring screw cutting processes to identify potential issues, troubleshooting and resolving machine malfunctions, and collaborating with engineers and production teams to develop and optimize screw cutting processes.

What are the essential skills required for a Screw Cutter?

Essential skills for a Screw Cutter include CNC machine operation, threading and tapping, material handling, quality control, safety compliance, and precision measurement.

What is the job outlook for Screw Cutters?

The job outlook for Screw Cutters is expected to be good, as the demand for skilled manufacturing professionals continues to grow.

What are the key responsibilities of a Screw Cutter?

Key responsibilities of a Screw Cutter include operating CNC screw cutting machines, establishing and maintaining optimal machine settings, inspecting and measuring screws to ensure they meet specifications, monitoring screw cutting processes to identify potential issues, troubleshooting and resolving machine malfunctions, and collaborating with engineers and production teams to develop and optimize screw cutting processes.

What is the difference between a Screw Cutter and a Machine Operator?

While Screw Cutters and Machine Operators both work with machinery, Screw Cutters specialize in operating CNC screw cutting machines to produce screws, while Machine Operators may operate a variety of machines in a manufacturing setting.

How can I become a Screw Cutter?

To become a Screw Cutter, you typically need to have a high school diploma or equivalent and some experience working in a manufacturing setting. You may also consider obtaining an associate’s degree or certificate in manufacturing technology or a related field.

What are the career growth opportunities for Screw Cutters?

Screw Cutters with experience and additional training may advance to positions such as CNC programmer, quality control inspector, or supervisor in a manufacturing setting.