Are you a seasoned Sealer Operator seeking a new career path? Discover our professionally built Sealer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

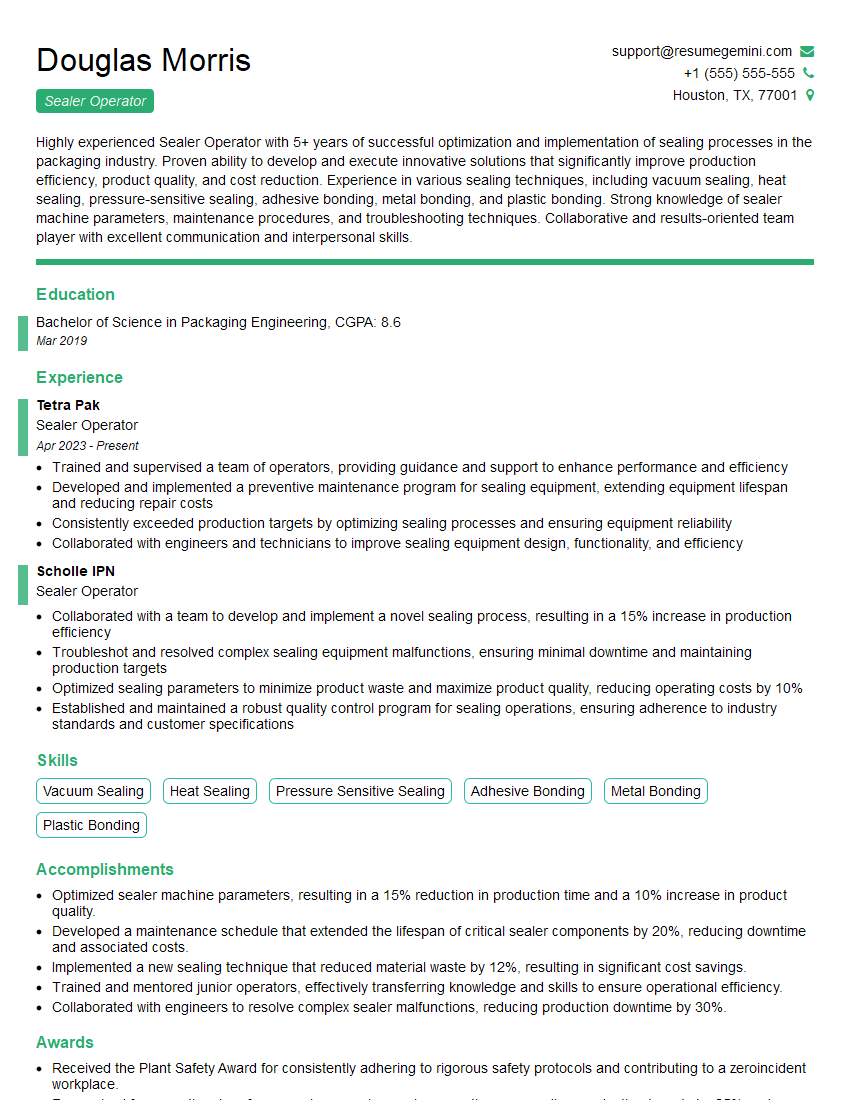

Douglas Morris

Sealer Operator

Summary

Highly experienced Sealer Operator with 5+ years of successful optimization and implementation of sealing processes in the packaging industry. Proven ability to develop and execute innovative solutions that significantly improve production efficiency, product quality, and cost reduction. Experience in various sealing techniques, including vacuum sealing, heat sealing, pressure-sensitive sealing, adhesive bonding, metal bonding, and plastic bonding. Strong knowledge of sealer machine parameters, maintenance procedures, and troubleshooting techniques. Collaborative and results-oriented team player with excellent communication and interpersonal skills.

Education

Bachelor of Science in Packaging Engineering

March 2019

Skills

- Vacuum Sealing

- Heat Sealing

- Pressure Sensitive Sealing

- Adhesive Bonding

- Metal Bonding

- Plastic Bonding

Work Experience

Sealer Operator

- Trained and supervised a team of operators, providing guidance and support to enhance performance and efficiency

- Developed and implemented a preventive maintenance program for sealing equipment, extending equipment lifespan and reducing repair costs

- Consistently exceeded production targets by optimizing sealing processes and ensuring equipment reliability

- Collaborated with engineers and technicians to improve sealing equipment design, functionality, and efficiency

Sealer Operator

- Collaborated with a team to develop and implement a novel sealing process, resulting in a 15% increase in production efficiency

- Troubleshot and resolved complex sealing equipment malfunctions, ensuring minimal downtime and maintaining production targets

- Optimized sealing parameters to minimize product waste and maximize product quality, reducing operating costs by 10%

- Established and maintained a robust quality control program for sealing operations, ensuring adherence to industry standards and customer specifications

Accomplishments

- Optimized sealer machine parameters, resulting in a 15% reduction in production time and a 10% increase in product quality.

- Developed a maintenance schedule that extended the lifespan of critical sealer components by 20%, reducing downtime and associated costs.

- Implemented a new sealing technique that reduced material waste by 12%, resulting in significant cost savings.

- Trained and mentored junior operators, effectively transferring knowledge and skills to ensure operational efficiency.

- Collaborated with engineers to resolve complex sealer malfunctions, reducing production downtime by 30%.

Awards

- Received the Plant Safety Award for consistently adhering to rigorous safety protocols and contributing to a zeroincident workplace.

- Recognized for exceptional performance in managing sealer operations, exceeding production targets by 25% and maintaining high product quality.

- Received the Employee of the Month award for consistently exceeding expectations and demonstrating a positive attitude in the workplace.

- Recognized for innovative problemsolving, suggesting improvements that streamlined sealer operations and increased productivity.

Certificates

- ISO 90012015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sealer Operator

- Quantify your accomplishments with specific metrics and results to showcase the impact of your contributions.

- Highlight your knowledge of different sealing techniques and equipment, demonstrating your versatility and expertise.

- Emphasize your problem-solving abilities and experience in troubleshooting and resolving machine malfunctions.

- Showcase your commitment to safety and quality by mentioning your adherence to established protocols and standards.

Essential Experience Highlights for a Strong Sealer Operator Resume

- Operate and maintain a variety of sealing machines to seal and package products

- Monitor and adjust machine settings to ensure optimal sealing quality and production efficiency

- Troubleshoot and resolve machine malfunctions to minimize downtime and maintain production schedules

- Perform preventive maintenance and repairs to extend the lifespan of sealing equipment

- Collaborate with production and engineering teams to identify and implement process improvements

- Train and supervise junior operators to ensure operational efficiency and adherence to safety protocols

- Maintain a clean and organized work area, adhering to established quality and safety standards

Frequently Asked Questions (FAQ’s) For Sealer Operator

What are the key skills required to be a successful Sealer Operator?

Key skills for a Sealer Operator include proficiency in operating and maintaining sealing machines; understanding of sealing techniques, materials, and equipment; problem-solving and troubleshooting abilities; and adherence to safety and quality standards.

What are the different types of sealing techniques used in the industry?

Common sealing techniques include vacuum sealing, heat sealing, pressure-sensitive sealing, adhesive bonding, metal bonding, and plastic bonding. Each technique has its unique advantages and applications depending on the materials and product requirements.

What is the role of a Sealer Operator in ensuring product quality?

Sealer Operators play a crucial role in ensuring product quality by maintaining optimal sealing parameters, monitoring machine performance, and troubleshooting any issues that may affect seal integrity. They ensure that products meet the required specifications and are protected from contamination or spoilage.

How can automation impact the role of a Sealer Operator?

Automation in sealing processes can enhance efficiency and reduce manual labor. Sealer Operators can leverage automated systems for tasks such as machine setup, monitoring, and data collection. This allows them to focus on higher-level tasks like quality control, process optimization, and maintenance.

What are the career advancement opportunities for a Sealer Operator?

With experience and additional training, Sealer Operators can advance to roles such as Production Supervisor, Maintenance Technician, or Quality Control Inspector. They may also specialize in a particular sealing technology or industry, becoming experts in their field.

What is the expected salary range for a Sealer Operator?

The salary range for a Sealer Operator can vary depending on factors such as experience, location, and industry. According to Salary.com, the average salary for Sealer Operators in the United States is around $35,000 to $50,000 per year.

What are the safety precautions that a Sealer Operator should follow?

Sealer Operators should follow established safety protocols, including wearing appropriate personal protective equipment (PPE), being aware of potential hazards, and adhering to lockout/tagout procedures. Regular training and adherence to safety guidelines are essential to prevent accidents and injuries.

How can a Sealer Operator stay updated with the latest industry trends and advancements?

To stay updated, Sealer Operators can attend industry conferences, workshops, and training programs. They can also read trade publications, participate in online forums, and connect with other professionals in the field. Continuous learning and professional development are crucial for staying abreast of new technologies and best practices.