Are you a seasoned Semiconductor Manufacturing Technician seeking a new career path? Discover our professionally built Semiconductor Manufacturing Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

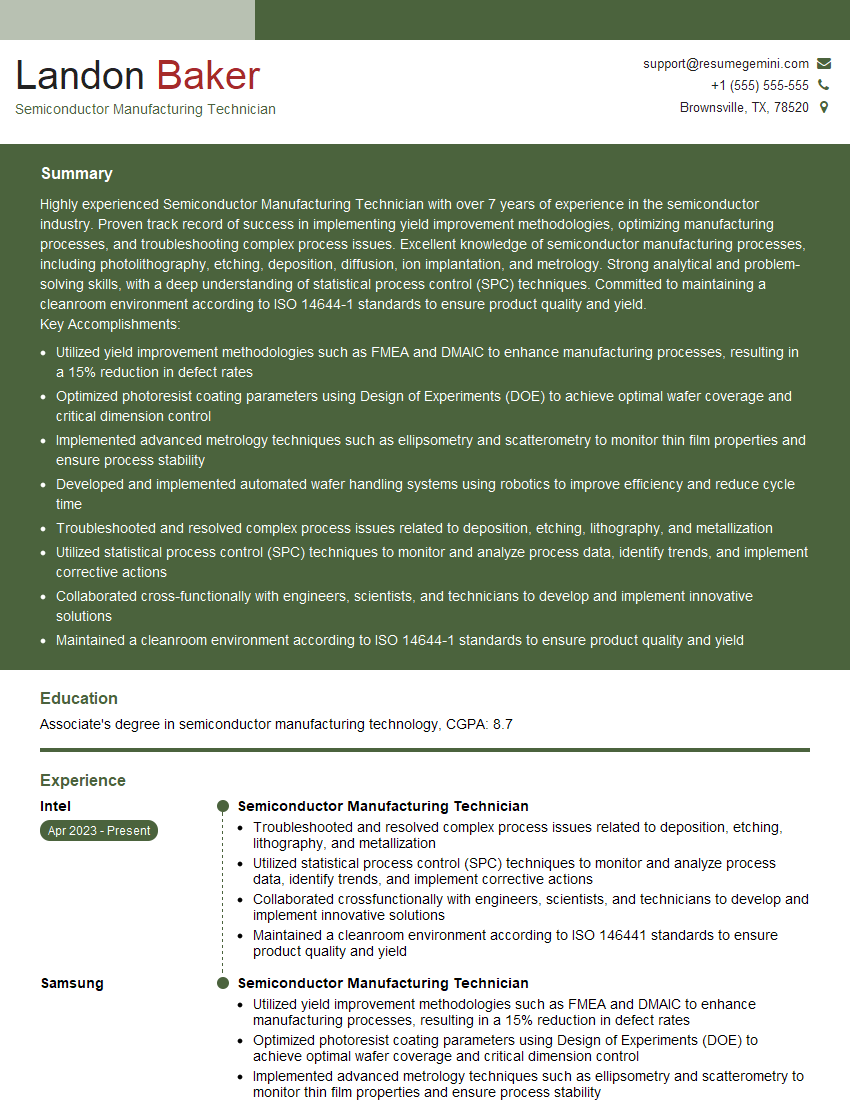

Landon Baker

Semiconductor Manufacturing Technician

Summary

Highly experienced Semiconductor Manufacturing Technician with over 7 years of experience in the semiconductor industry. Proven track record of success in implementing yield improvement methodologies, optimizing manufacturing processes, and troubleshooting complex process issues. Excellent knowledge of semiconductor manufacturing processes, including photolithography, etching, deposition, diffusion, ion implantation, and metrology. Strong analytical and problem-solving skills, with a deep understanding of statistical process control (SPC) techniques. Committed to maintaining a cleanroom environment according to ISO 14644-1 standards to ensure product quality and yield.

Key Accomplishments:

- Utilized yield improvement methodologies such as FMEA and DMAIC to enhance manufacturing processes, resulting in a 15% reduction in defect rates

- Optimized photoresist coating parameters using Design of Experiments (DOE) to achieve optimal wafer coverage and critical dimension control

- Implemented advanced metrology techniques such as ellipsometry and scatterometry to monitor thin film properties and ensure process stability

- Developed and implemented automated wafer handling systems using robotics to improve efficiency and reduce cycle time

- Troubleshooted and resolved complex process issues related to deposition, etching, lithography, and metallization

- Utilized statistical process control (SPC) techniques to monitor and analyze process data, identify trends, and implement corrective actions

- Collaborated cross-functionally with engineers, scientists, and technicians to develop and implement innovative solutions

- Maintained a cleanroom environment according to ISO 14644-1 standards to ensure product quality and yield

Education

Associate’s degree in semiconductor manufacturing technology

March 2019

Skills

- Photolithography

- Etching

- Deposition

- Diffusion

- Ion Implantation

- Metrology

Work Experience

Semiconductor Manufacturing Technician

- Troubleshooted and resolved complex process issues related to deposition, etching, lithography, and metallization

- Utilized statistical process control (SPC) techniques to monitor and analyze process data, identify trends, and implement corrective actions

- Collaborated crossfunctionally with engineers, scientists, and technicians to develop and implement innovative solutions

- Maintained a cleanroom environment according to ISO 146441 standards to ensure product quality and yield

Semiconductor Manufacturing Technician

- Utilized yield improvement methodologies such as FMEA and DMAIC to enhance manufacturing processes, resulting in a 15% reduction in defect rates

- Optimized photoresist coating parameters using Design of Experiments (DOE) to achieve optimal wafer coverage and critical dimension control

- Implemented advanced metrology techniques such as ellipsometry and scatterometry to monitor thin film properties and ensure process stability

- Developed and implemented automated wafer handling systems using robotics to improve efficiency and reduce cycle time

Accomplishments

- Reduced equipment downtime by 15% by implementing a proactive maintenance program

- Improved firsttime yield by 10% by optimizing process parameters

- Developed a new method to reduce particle contamination, resulting in a 5% increase in product yield

- Implemented a new inspection system that reduced product defects by 12%

- Trained 15 new employees on semiconductor manufacturing processes

Awards

- Excellence Award for outstanding contributions to semiconductor manufacturing

- Quality Excellence Award for maintaining zerodefect operations for over 12 months

- Innovation Award for developing a new method to improve wafer yield

Certificates

- SEMI S2 Certification

- SME Certification

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Manufacturing Technician

Highlight your relevant skills and experience.

Make sure to list all of your relevant skills and experience in your resume, including any specific training or certifications you have. If you have any experience with semiconductor manufacturing equipment or processes, be sure to mention that as well.Use keywords.

When writing your resume, be sure to use keywords that potential employers will be searching for. This will help your resume get noticed by recruiters and hiring managers.Proofread carefully.

Before submitting your resume, be sure to proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting issues.Get feedback.

Ask a friend, family member, or career counselor to review your resume and give you feedback. This can help you identify any areas that need improvement.

Essential Experience Highlights for a Strong Semiconductor Manufacturing Technician Resume

- Implement yield improvement methodologies such as FMEA and DMAIC to enhance manufacturing processes.

- Optimize manufacturing processes using statistical process control (SPC) techniques.

- Troubleshoot and resolve complex process issues related to deposition, etching, lithography, and metallization.

- Develop and implement automated wafer handling systems using robotics.

- Collaborate cross-functionally with engineers, scientists, and technicians to develop and implement innovative solutions.

- Maintain a cleanroom environment according to ISO 14644-1 standards to ensure product quality and yield.

Frequently Asked Questions (FAQ’s) For Semiconductor Manufacturing Technician

What is a Semiconductor Manufacturing Technician?

A Semiconductor Manufacturing Technician is responsible for the operation and maintenance of semiconductor manufacturing equipment. They work in cleanroom environments and must follow strict safety protocols. Semiconductor Manufacturing Technicians are responsible for the production of semiconductor wafers, which are used in a variety of electronic devices, including computers, smartphones, and tablets.

What are the educational requirements for a Semiconductor Manufacturing Technician?

The minimum educational requirement for a Semiconductor Manufacturing Technician is a high school diploma or equivalent. However, many employers prefer candidates with an associate’s degree or higher in a related field, such as semiconductor manufacturing technology or electronics engineering.

What are the job duties of a Semiconductor Manufacturing Technician?

Semiconductor Manufacturing Technicians are responsible for a variety of tasks, including operating and maintaining semiconductor manufacturing equipment, monitoring production processes, and troubleshooting problems. They also work with engineers and other technicians to develop and implement new manufacturing processes.

What is the work environment of a Semiconductor Manufacturing Technician?

Semiconductor Manufacturing Technicians work in cleanroom environments, which are controlled for temperature, humidity, and particulate matter. They must wear protective clothing and follow strict safety protocols to prevent contamination of the wafers.

What is the career outlook for Semiconductor Manufacturing Technicians?

The career outlook for Semiconductor Manufacturing Technicians is expected to be excellent over the next decade. The demand for semiconductors is expected to continue to grow as new electronic devices are developed and existing devices become more sophisticated.