Are you a seasoned Semiconductor Wafer Processing Inspector seeking a new career path? Discover our professionally built Semiconductor Wafer Processing Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

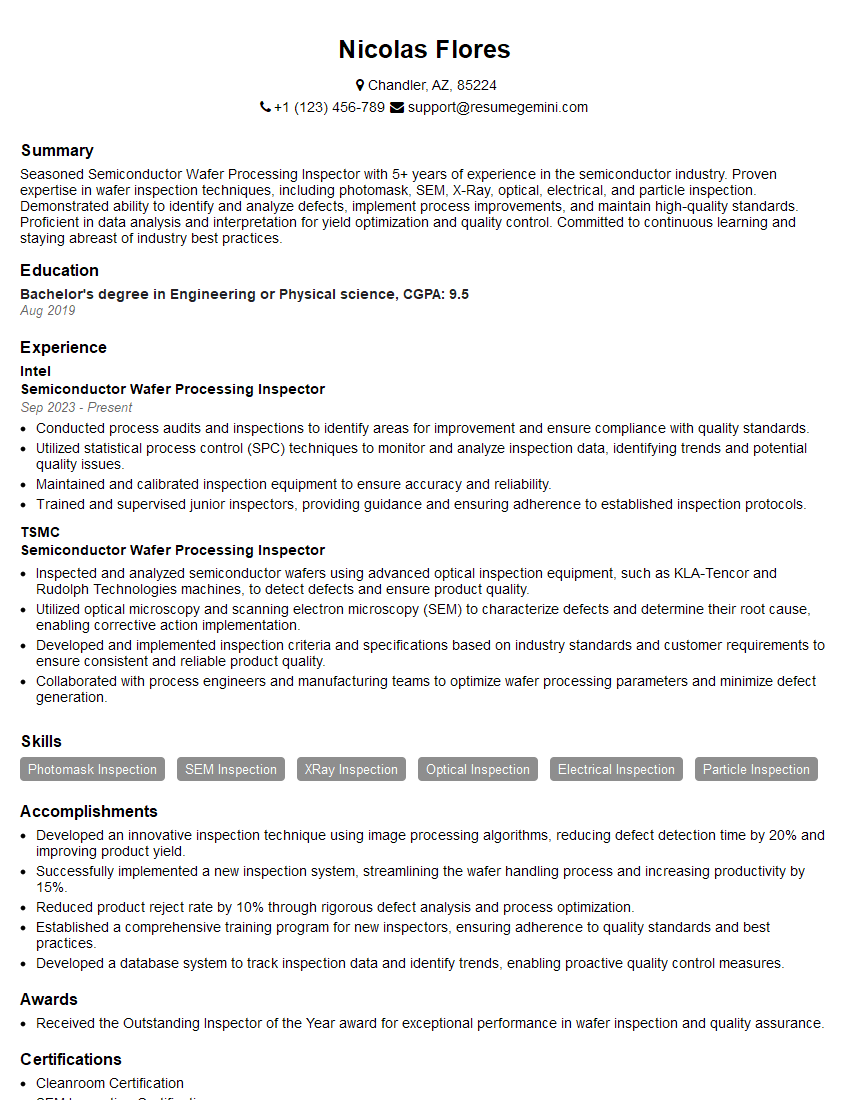

Nicolas Flores

Semiconductor Wafer Processing Inspector

Summary

Seasoned Semiconductor Wafer Processing Inspector with 5+ years of experience in the semiconductor industry. Proven expertise in wafer inspection techniques, including photomask, SEM, X-Ray, optical, electrical, and particle inspection. Demonstrated ability to identify and analyze defects, implement process improvements, and maintain high-quality standards. Proficient in data analysis and interpretation for yield optimization and quality control. Committed to continuous learning and staying abreast of industry best practices.

Education

Bachelor’s degree in Engineering or Physical science

August 2019

Skills

- Photomask Inspection

- SEM Inspection

- XRay Inspection

- Optical Inspection

- Electrical Inspection

- Particle Inspection

Work Experience

Semiconductor Wafer Processing Inspector

- Conducted process audits and inspections to identify areas for improvement and ensure compliance with quality standards.

- Utilized statistical process control (SPC) techniques to monitor and analyze inspection data, identifying trends and potential quality issues.

- Maintained and calibrated inspection equipment to ensure accuracy and reliability.

- Trained and supervised junior inspectors, providing guidance and ensuring adherence to established inspection protocols.

Semiconductor Wafer Processing Inspector

- Inspected and analyzed semiconductor wafers using advanced optical inspection equipment, such as KLA-Tencor and Rudolph Technologies machines, to detect defects and ensure product quality.

- Utilized optical microscopy and scanning electron microscopy (SEM) to characterize defects and determine their root cause, enabling corrective action implementation.

- Developed and implemented inspection criteria and specifications based on industry standards and customer requirements to ensure consistent and reliable product quality.

- Collaborated with process engineers and manufacturing teams to optimize wafer processing parameters and minimize defect generation.

Accomplishments

- Developed an innovative inspection technique using image processing algorithms, reducing defect detection time by 20% and improving product yield.

- Successfully implemented a new inspection system, streamlining the wafer handling process and increasing productivity by 15%.

- Reduced product reject rate by 10% through rigorous defect analysis and process optimization.

- Established a comprehensive training program for new inspectors, ensuring adherence to quality standards and best practices.

- Developed a database system to track inspection data and identify trends, enabling proactive quality control measures.

Awards

- Received the Outstanding Inspector of the Year award for exceptional performance in wafer inspection and quality assurance.

Certificates

- Cleanroom Certification

- SEM Inspection Certification

- SPC Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafer Processing Inspector

- Highlight your technical expertise in wafer inspection techniques and data analysis.

- Quantify your accomplishments with specific metrics and results.

- Showcase your problem-solving abilities and process improvement initiatives.

- Emphasize your commitment to quality and continuous learning.

Essential Experience Highlights for a Strong Semiconductor Wafer Processing Inspector Resume

- Conduct thorough wafer inspections using various techniques to detect and identify defects

- Analyze defect data to determine root causes and recommend corrective actions

- Develop and implement inspection procedures to ensure adherence to quality standards

- Collaborate with process engineers to improve wafer processing and reduce defects

- Train and mentor new inspectors to ensure consistent inspection practices

- Maintain and calibrate inspection equipment to ensure accuracy and reliability

- Document inspection results and generate reports for quality control purposes

Frequently Asked Questions (FAQ’s) For Semiconductor Wafer Processing Inspector

What are the primary responsibilities of a Semiconductor Wafer Processing Inspector?

Semiconductor Wafer Processing Inspectors are responsible for conducting thorough inspections of semiconductor wafers to identify and analyze defects. They develop and implement inspection procedures, collaborate with process engineers to improve wafer processing, train and mentor new inspectors, maintain and calibrate inspection equipment, and document inspection results.

What skills are required to be a successful Semiconductor Wafer Processing Inspector?

Successful Semiconductor Wafer Processing Inspectors possess a strong understanding of wafer inspection techniques, including photomask, SEM, X-Ray, optical, electrical, and particle inspection. They have excellent analytical and problem-solving skills, and are proficient in data interpretation and quality control. Additionally, they are detail-oriented, have strong communication skills, and are committed to maintaining a clean and safe work environment.

What are the career prospects for Semiconductor Wafer Processing Inspectors?

Semiconductor Wafer Processing Inspectors can advance their careers by specializing in a particular inspection technique, such as photomask inspection or SEM inspection. They can also move into management roles, such as Inspection Supervisor or Quality Control Manager. With experience and additional education, they may also transition into roles in process engineering or research and development.

What is the work environment like for Semiconductor Wafer Processing Inspectors?

Semiconductor Wafer Processing Inspectors typically work in cleanroom environments, which require special clothing and strict adherence to safety protocols. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What is the salary range for Semiconductor Wafer Processing Inspectors?

The salary range for Semiconductor Wafer Processing Inspectors varies depending on experience, skills, and location. According to Indeed, the average salary for a Semiconductor Wafer Processing Inspector in the United States is around $60,000 per year.

What are the educational requirements to become a Semiconductor Wafer Processing Inspector?

Most Semiconductor Wafer Processing Inspectors have a bachelor’s degree in engineering or a physical science, such as physics or chemistry. Some employers may also accept candidates with an associate’s degree in a related field, combined with relevant experience.