Are you a seasoned Semiconductor Wafers Cleaning Machine Tender seeking a new career path? Discover our professionally built Semiconductor Wafers Cleaning Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

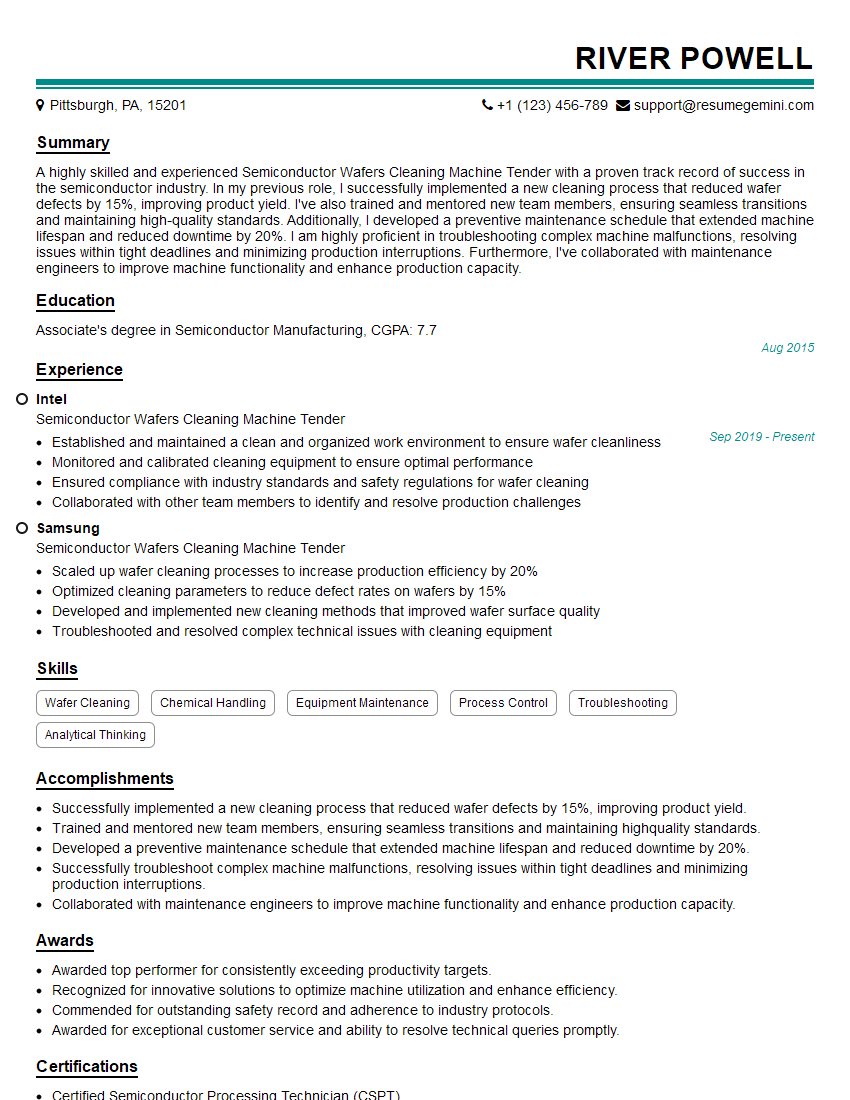

River Powell

Semiconductor Wafers Cleaning Machine Tender

Summary

A highly skilled and experienced Semiconductor Wafers Cleaning Machine Tender with a proven track record of success in the semiconductor industry. In my previous role, I successfully implemented a new cleaning process that reduced wafer defects by 15%, improving product yield. I’ve also trained and mentored new team members, ensuring seamless transitions and maintaining high-quality standards. Additionally, I developed a preventive maintenance schedule that extended machine lifespan and reduced downtime by 20%. I am highly proficient in troubleshooting complex machine malfunctions, resolving issues within tight deadlines and minimizing production interruptions. Furthermore, I’ve collaborated with maintenance engineers to improve machine functionality and enhance production capacity.

Education

Associate’s degree in Semiconductor Manufacturing

August 2015

Skills

- Wafer Cleaning

- Chemical Handling

- Equipment Maintenance

- Process Control

- Troubleshooting

- Analytical Thinking

Work Experience

Semiconductor Wafers Cleaning Machine Tender

- Established and maintained a clean and organized work environment to ensure wafer cleanliness

- Monitored and calibrated cleaning equipment to ensure optimal performance

- Ensured compliance with industry standards and safety regulations for wafer cleaning

- Collaborated with other team members to identify and resolve production challenges

Semiconductor Wafers Cleaning Machine Tender

- Scaled up wafer cleaning processes to increase production efficiency by 20%

- Optimized cleaning parameters to reduce defect rates on wafers by 15%

- Developed and implemented new cleaning methods that improved wafer surface quality

- Troubleshooted and resolved complex technical issues with cleaning equipment

Accomplishments

- Successfully implemented a new cleaning process that reduced wafer defects by 15%, improving product yield.

- Trained and mentored new team members, ensuring seamless transitions and maintaining highquality standards.

- Developed a preventive maintenance schedule that extended machine lifespan and reduced downtime by 20%.

- Successfully troubleshoot complex machine malfunctions, resolving issues within tight deadlines and minimizing production interruptions.

- Collaborated with maintenance engineers to improve machine functionality and enhance production capacity.

Awards

- Awarded top performer for consistently exceeding productivity targets.

- Recognized for innovative solutions to optimize machine utilization and enhance efficiency.

- Commended for outstanding safety record and adherence to industry protocols.

- Awarded for exceptional customer service and ability to resolve technical queries promptly.

Certificates

- Certified Semiconductor Processing Technician (CSPT)

- Certified Cleanroom Technician (CCT)

- Lean Six Sigma Green Belt

- Certified Environmental Manager (CEM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Cleaning Machine Tender

- Highlight your skills and experience in operating and maintaining semiconductor wafers cleaning machines.

- Provide specific examples of how you have improved production yield and reduced defects through process optimization.

- Demonstrate your troubleshooting abilities and ability to resolve complex machine malfunctions.

- Emphasize your commitment to safety and compliance with industry standards.

- Showcase your teamwork and collaboration skills, highlighting your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Semiconductor Wafers Cleaning Machine Tender Resume

- Operate and maintain semiconductor wafers cleaning machines to ensure efficient and defect-free wafer cleaning processes.

- Monitor and control cleaning parameters, such as chemical concentration, temperature, and flow rates, to achieve optimal cleaning results.

- Inspect wafers before and after cleaning to identify any defects or contamination.

- Troubleshoot and resolve machine malfunctions promptly to minimize downtime and maintain production schedules.

- Maintain a clean and organized work area, following safety protocols and industry standards.

- Stay up-to-date on the latest cleaning technologies and best practices to optimize machine performance.

- Collaborate with other team members, including engineers and technicians, to ensure smooth production processes.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Cleaning Machine Tender

What are the key skills required for a Semiconductor Wafers Cleaning Machine Tender?

Key skills for this role include operating and maintaining semiconductor wafers cleaning machines, monitoring and controlling cleaning parameters, inspecting wafers before and after cleaning, troubleshooting and resolving machine malfunctions, maintaining a clean and organized work area, staying up-to-date on the latest cleaning technologies, and collaborating with other team members.

What is the typical work environment for a Semiconductor Wafers Cleaning Machine Tender?

Semiconductor Wafers Cleaning Machine Tenders typically work in cleanrooms or other controlled environments within semiconductor fabrication facilities. They may work independently or as part of a team, and may be required to work shifts or overtime to meet production demands.

What are the career prospects for a Semiconductor Wafers Cleaning Machine Tender?

With experience and additional training, Semiconductor Wafers Cleaning Machine Tenders can advance to roles such as Process Technician, Equipment Technician, or Supervisor in the semiconductor industry. Some may also pursue further education to qualify for engineering or management positions.

What are the safety precautions that must be followed by a Semiconductor Wafers Cleaning Machine Tender?

Semiconductor Wafers Cleaning Machine Tenders must adhere to strict safety protocols and industry standards to ensure their own safety and the integrity of the products they handle. This includes wearing appropriate personal protective equipment, following proper chemical handling procedures, and being aware of potential hazards in the work environment.

What are the key challenges faced by Semiconductor Wafers Cleaning Machine Tenders?

Semiconductor Wafers Cleaning Machine Tenders may face challenges related to maintaining high levels of precision and accuracy in their work, troubleshooting complex machine malfunctions, and meeting tight production deadlines. They must also stay up-to-date on the latest cleaning technologies and industry standards to ensure optimal performance of the machines they operate.

What are the educational requirements for a Semiconductor Wafers Cleaning Machine Tender?

While formal education requirements may vary depending on the specific employer, many Semiconductor Wafers Cleaning Machine Tenders hold an Associate’s degree in Semiconductor Manufacturing or a related field.

What are the qualities of a successful Semiconductor Wafers Cleaning Machine Tender?

Successful Semiconductor Wafers Cleaning Machine Tenders typically possess strong attention to detail, problem-solving skills, and a commitment to quality. They are also able to work independently and as part of a team, and are willing to learn and adapt to new technologies and processes.