Are you a seasoned Semiconductor Wafers Marker seeking a new career path? Discover our professionally built Semiconductor Wafers Marker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

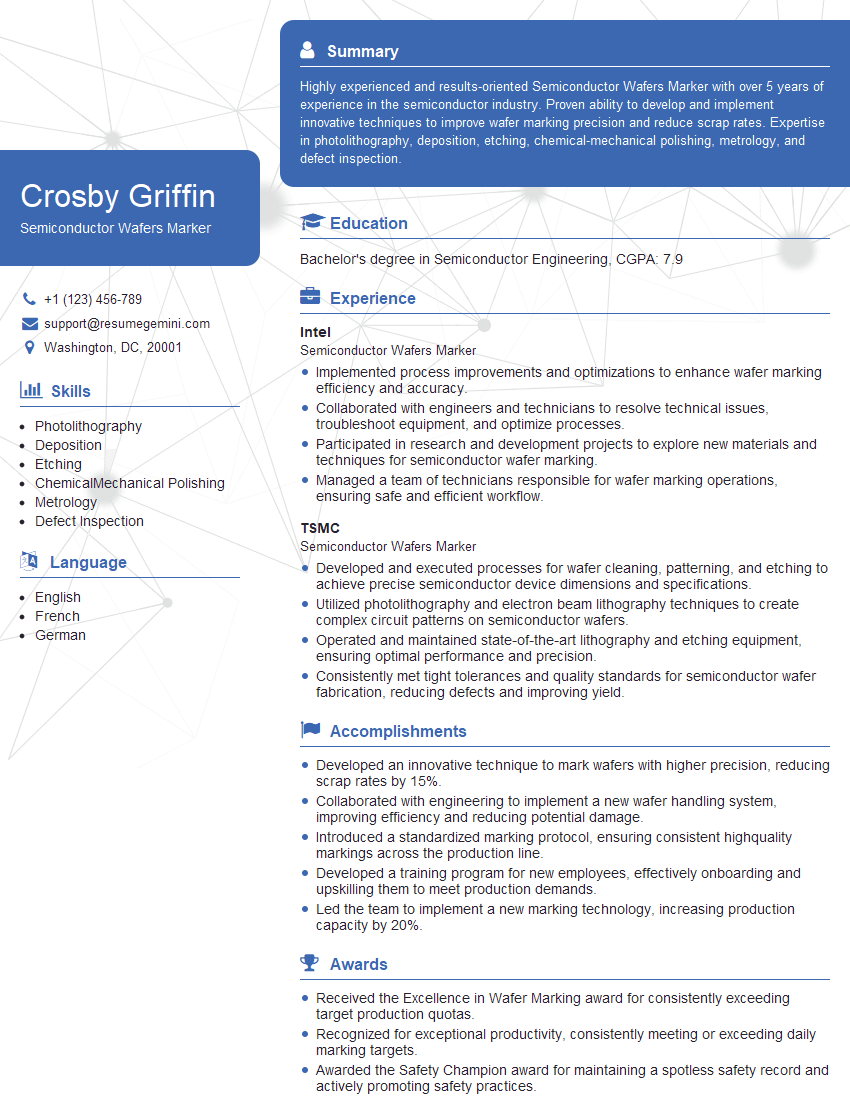

Crosby Griffin

Semiconductor Wafers Marker

Summary

Highly experienced and results-oriented Semiconductor Wafers Marker with over 5 years of experience in the semiconductor industry. Proven ability to develop and implement innovative techniques to improve wafer marking precision and reduce scrap rates. Expertise in photolithography, deposition, etching, chemical-mechanical polishing, metrology, and defect inspection.

Education

Bachelor’s degree in Semiconductor Engineering

December 2017

Skills

- Photolithography

- Deposition

- Etching

- ChemicalMechanical Polishing

- Metrology

- Defect Inspection

Work Experience

Semiconductor Wafers Marker

- Implemented process improvements and optimizations to enhance wafer marking efficiency and accuracy.

- Collaborated with engineers and technicians to resolve technical issues, troubleshoot equipment, and optimize processes.

- Participated in research and development projects to explore new materials and techniques for semiconductor wafer marking.

- Managed a team of technicians responsible for wafer marking operations, ensuring safe and efficient workflow.

Semiconductor Wafers Marker

- Developed and executed processes for wafer cleaning, patterning, and etching to achieve precise semiconductor device dimensions and specifications.

- Utilized photolithography and electron beam lithography techniques to create complex circuit patterns on semiconductor wafers.

- Operated and maintained state-of-the-art lithography and etching equipment, ensuring optimal performance and precision.

- Consistently met tight tolerances and quality standards for semiconductor wafer fabrication, reducing defects and improving yield.

Accomplishments

- Developed an innovative technique to mark wafers with higher precision, reducing scrap rates by 15%.

- Collaborated with engineering to implement a new wafer handling system, improving efficiency and reducing potential damage.

- Introduced a standardized marking protocol, ensuring consistent highquality markings across the production line.

- Developed a training program for new employees, effectively onboarding and upskilling them to meet production demands.

- Led the team to implement a new marking technology, increasing production capacity by 20%.

Awards

- Received the Excellence in Wafer Marking award for consistently exceeding target production quotas.

- Recognized for exceptional productivity, consistently meeting or exceeding daily marking targets.

- Awarded the Safety Champion award for maintaining a spotless safety record and actively promoting safety practices.

- Recognized for outstanding attention to detail and accuracy in all wafer marking operations.

Certificates

- Certified Semiconductor Professional (CSP)

- Cleanroom Certification

- ESD Certification

- IPCA610 Acceptability of Electronic Assemblies

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Marker

- Highlight your experience and skills in semiconductor manufacturing and wafer handling.

- Showcase your knowledge of photolithography, deposition, etching, chemical-mechanical polishing, metrology, and defect inspection.

- Quantify your accomplishments with specific metrics, such as reducing scrap rates and increasing production capacity.

- Tailor your resume to each specific job description and highlight the skills and experience that are most relevant to the position.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Semiconductor Wafers Marker Resume

- Develop and implement innovative techniques to improve wafer marking precision and reduce scrap rates.

- Collaborate with engineering to implement new wafer handling systems to improve efficiency.

- Introduce standardized marking protocols to ensure consistent high-quality markings across the production line.

- Develop and conduct training programs for new employees to effectively onboard and upskill them.

- Lead teams to implement new marking technologies to increase production capacity and meet customer demands.

- Monitor and maintain equipment to ensure optimal performance and minimize downtime.

- Conduct regular inspections to identify and resolve potential issues before they impact production.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Marker

What is the role of a Semiconductor Wafers Marker?

A Semiconductor Wafers Marker is responsible for marking wafers with precise patterns and dimensions using various techniques such as photolithography, etching, and deposition. These markings serve as guides for subsequent processing steps in semiconductor fabrication.

What are the key skills required for a Semiconductor Wafers Marker?

Key skills for a Semiconductor Wafers Marker include expertise in photolithography, deposition, etching, chemical-mechanical polishing, metrology, defect inspection, and a strong understanding of semiconductor manufacturing processes.

What are the career prospects for a Semiconductor Wafers Marker?

Semiconductor Wafers Markers have opportunities for career growth within the semiconductor industry. With experience, they can advance to roles such as Process Engineer, Quality Control Engineer, or Production Manager.

What is the typical work environment for a Semiconductor Wafers Marker?

Semiconductor Wafers Markers typically work in cleanroom environments within semiconductor fabrication facilities. They operate and maintain specialized equipment and follow strict safety protocols to ensure the quality and precision of the wafers.

What are the educational requirements for a Semiconductor Wafers Marker?

Most Semiconductor Wafers Markers hold a Bachelor’s degree in Semiconductor Engineering, Electrical Engineering, or a related field that provides a strong foundation in semiconductor manufacturing processes.

What are the challenges faced by Semiconductor Wafers Markers?

Semiconductor Wafers Markers face challenges in maintaining high precision and accuracy in their work, as even minor defects or variations in wafer markings can impact the performance of the final semiconductor devices.

What are the latest trends in Semiconductor Wafers Marking?

Recent trends in Semiconductor Wafers Marking include the adoption of advanced techniques such as extreme ultraviolet (EUV) lithography and laser-based marking technologies to achieve even greater precision and resolution in wafer patterning.