Are you a seasoned Semiconductor Wafers Photographic Processor seeking a new career path? Discover our professionally built Semiconductor Wafers Photographic Processor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

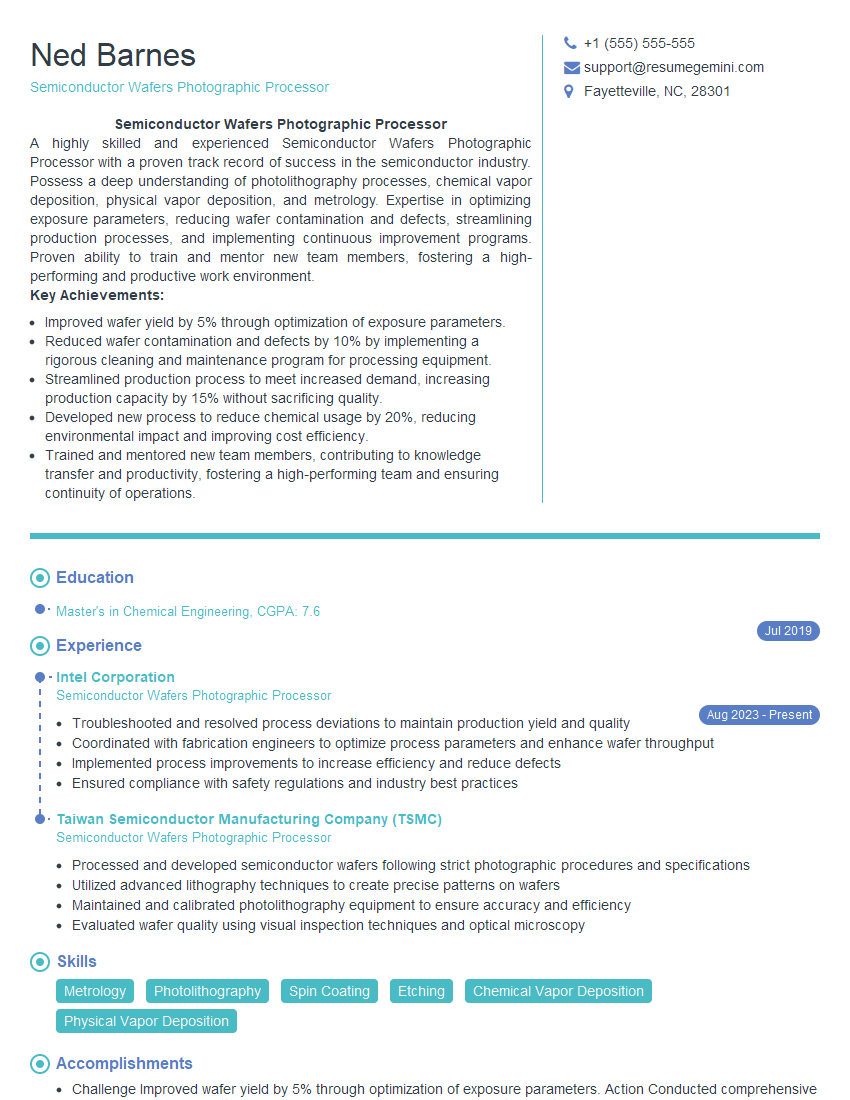

Ned Barnes

Semiconductor Wafers Photographic Processor

Summary

Semiconductor Wafers Photographic Processor

A highly skilled and experienced Semiconductor Wafers Photographic Processor with a proven track record of success in the semiconductor industry. Possess a deep understanding of photolithography processes, chemical vapor deposition, physical vapor deposition, and metrology. Expertise in optimizing exposure parameters, reducing wafer contamination and defects, streamlining production processes, and implementing continuous improvement programs. Proven ability to train and mentor new team members, fostering a high-performing and productive work environment.

Key Achievements:

- Improved wafer yield by 5% through optimization of exposure parameters.

- Reduced wafer contamination and defects by 10% by implementing a rigorous cleaning and maintenance program for processing equipment.

- Streamlined production process to meet increased demand, increasing production capacity by 15% without sacrificing quality.

- Developed new process to reduce chemical usage by 20%, reducing environmental impact and improving cost efficiency.

- Trained and mentored new team members, contributing to knowledge transfer and productivity, fostering a high-performing team and ensuring continuity of operations.

Education

Master’s in Chemical Engineering

July 2019

Skills

- Metrology

- Photolithography

- Spin Coating

- Etching

- Chemical Vapor Deposition

- Physical Vapor Deposition

Work Experience

Semiconductor Wafers Photographic Processor

- Troubleshooted and resolved process deviations to maintain production yield and quality

- Coordinated with fabrication engineers to optimize process parameters and enhance wafer throughput

- Implemented process improvements to increase efficiency and reduce defects

- Ensured compliance with safety regulations and industry best practices

Semiconductor Wafers Photographic Processor

- Processed and developed semiconductor wafers following strict photographic procedures and specifications

- Utilized advanced lithography techniques to create precise patterns on wafers

- Maintained and calibrated photolithography equipment to ensure accuracy and efficiency

- Evaluated wafer quality using visual inspection techniques and optical microscopy

Accomplishments

- Challenge Improved wafer yield by 5% through optimization of exposure parameters. Action Conducted comprehensive analysis of exposure settings, including dosage, focus, and alignment. Result Increased wafer yield and reduced production costs.

- Challenge Reduced wafer contamination and defects by 10%. Action Implemented a rigorous cleaning and maintenance program for processing equipment. Result Enhanced product quality and increased customer satisfaction.

- Challenge Streamlined production process to meet increased demand. Action Implemented a continuous improvement program to identify and eliminate bottlenecks. Result Increased production capacity by 15% without sacrificing quality.

- Challenge Developed new process to reduce chemical usage by 20%. Action Researched alternative chemicals and optimized process parameters. Result Reduced environmental impact and improved cost efficiency.

- Challenge Trained and mentored new team members, contributing to knowledge transfer and productivity. Action Provided comprehensive training and guidance to ensure proficiency. Result Fostered a highperforming team and ensured continuity of operations.

Awards

- Siemens Gold Star Award for Excellence in Semiconductor Wafer Processing

- Intel Supplier Recognition Award for Outstanding Contributions to Wafer Photolithography

- TSMC BestinClass Award for Wafer Photographic Processing

Certificates

- ASML PSM Certification

- Nikon NSR Certification

- Lam Research Fabspeed Certification

- Tokyo Electron TEL Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Semiconductor Wafers Photographic Processor

- Highlight your technical skills. As a Semiconductor Wafers Photographic Processor, you should possess a strong understanding of photolithography, chemical vapor deposition, physical vapor deposition, and metrology. Be sure to list these skills prominently on your resume.

- Quantify your accomplishments. When describing your experience, use specific numbers and metrics to quantify your accomplishments. For example, instead of saying “Improved wafer yield,” you could say “Improved wafer yield by 5% through optimization of exposure parameters.”

- Use action verbs. When writing your resume, use action verbs to describe your responsibilities. This will make your resume more dynamic and engaging.

- Proofread carefully. Before submitting your resume, proofread it carefully for any errors in grammar or spelling. A well-written resume will make a positive impression on potential employers.

Essential Experience Highlights for a Strong Semiconductor Wafers Photographic Processor Resume

- Operate and maintain photographic processing equipment used in the manufacturing of semiconductor wafers.

- Control exposure parameters, such as dosage, focus, and alignment, to ensure the production of high-quality wafers.

- Monitor and maintain the cleanliness of the processing environment to minimize contamination and defects.

- Troubleshoot and resolve equipment malfunctions and process issues to ensure smooth production.

- Collaborate with engineers and other team members to improve processes and optimize production yields.

- Adhere to safety protocols and maintain a safe work environment.

Frequently Asked Questions (FAQ’s) For Semiconductor Wafers Photographic Processor

What is a Semiconductor Wafers Photographic Processor?

A Semiconductor Wafers Photographic Processor is responsible for operating and maintaining photographic processing equipment used in the manufacturing of semiconductor wafers. They control exposure parameters, such as dosage, focus, and alignment, to ensure the production of high-quality wafers. They also monitor and maintain the cleanliness of the processing environment to minimize contamination and defects.

What are the key skills required for a Semiconductor Wafers Photographic Processor?

The key skills required for a Semiconductor Wafers Photographic Processor include a strong understanding of photolithography, chemical vapor deposition, physical vapor deposition, and metrology. They should also possess excellent troubleshooting and problem-solving skills, as well as the ability to work in a clean and sterile environment.

What are the career prospects for a Semiconductor Wafers Photographic Processor?

The career prospects for a Semiconductor Wafers Photographic Processor are good. The semiconductor industry is growing rapidly, and there is a high demand for skilled workers. With experience, Semiconductor Wafers Photographic Processors can advance to supervisory or management positions.

What is the average salary for a Semiconductor Wafers Photographic Processor?

The average salary for a Semiconductor Wafers Photographic Processor is around $60,000 per year. However, salaries can vary depending on experience, location, and company size.

What are the working conditions like for a Semiconductor Wafers Photographic Processor?

Semiconductor Wafers Photographic Processors typically work in clean and sterile environments. They may be required to wear protective clothing, such as gloves and masks, to prevent contamination. The work can be physically demanding, as they may be required to lift heavy objects or stand for long periods of time.

What is the job outlook for a Semiconductor Wafers Photographic Processor?

The job outlook for a Semiconductor Wafers Photographic Processor is expected to be good over the next few years. The semiconductor industry is growing rapidly, and there is a high demand for skilled workers.