Are you a seasoned Shear Setter seeking a new career path? Discover our professionally built Shear Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

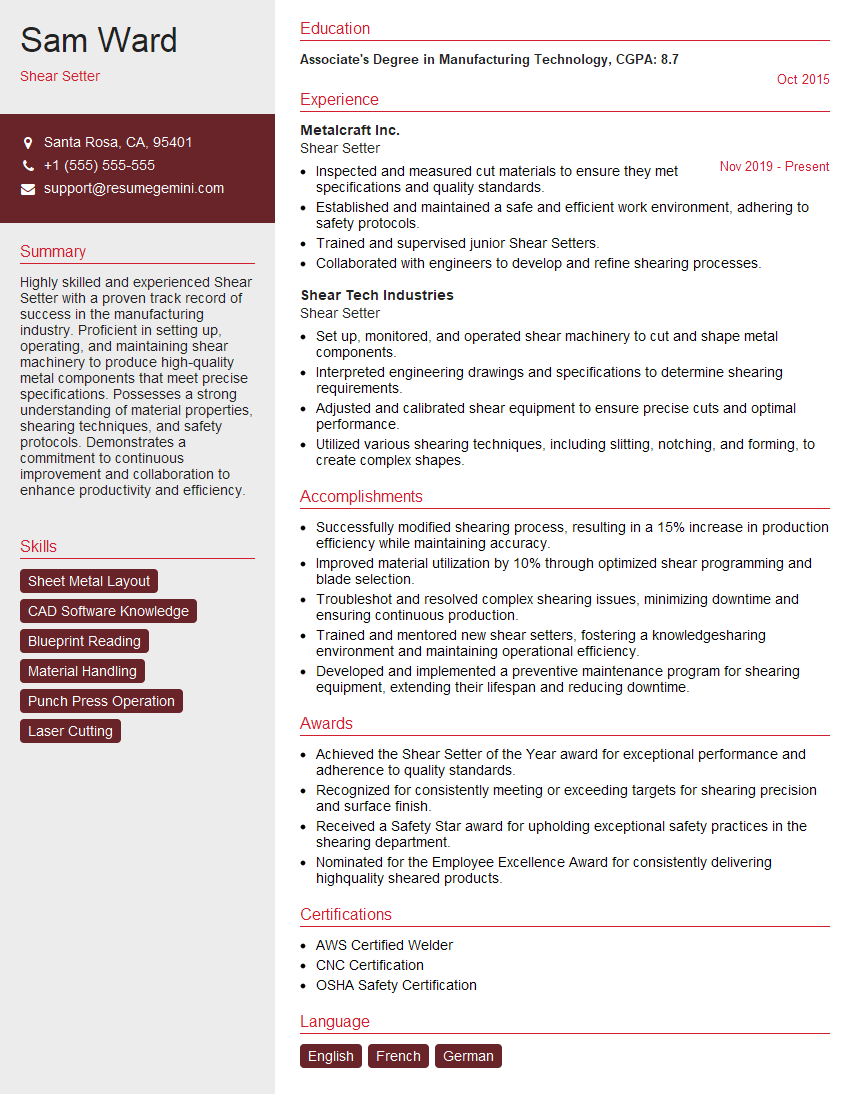

Sam Ward

Shear Setter

Summary

Highly skilled and experienced Shear Setter with a proven track record of success in the manufacturing industry. Proficient in setting up, operating, and maintaining shear machinery to produce high-quality metal components that meet precise specifications. Possesses a strong understanding of material properties, shearing techniques, and safety protocols. Demonstrates a commitment to continuous improvement and collaboration to enhance productivity and efficiency.

Education

Associate’s Degree in Manufacturing Technology

October 2015

Skills

- Sheet Metal Layout

- CAD Software Knowledge

- Blueprint Reading

- Material Handling

- Punch Press Operation

- Laser Cutting

Work Experience

Shear Setter

- Inspected and measured cut materials to ensure they met specifications and quality standards.

- Established and maintained a safe and efficient work environment, adhering to safety protocols.

- Trained and supervised junior Shear Setters.

- Collaborated with engineers to develop and refine shearing processes.

Shear Setter

- Set up, monitored, and operated shear machinery to cut and shape metal components.

- Interpreted engineering drawings and specifications to determine shearing requirements.

- Adjusted and calibrated shear equipment to ensure precise cuts and optimal performance.

- Utilized various shearing techniques, including slitting, notching, and forming, to create complex shapes.

Accomplishments

- Successfully modified shearing process, resulting in a 15% increase in production efficiency while maintaining accuracy.

- Improved material utilization by 10% through optimized shear programming and blade selection.

- Troubleshot and resolved complex shearing issues, minimizing downtime and ensuring continuous production.

- Trained and mentored new shear setters, fostering a knowledgesharing environment and maintaining operational efficiency.

- Developed and implemented a preventive maintenance program for shearing equipment, extending their lifespan and reducing downtime.

Awards

- Achieved the Shear Setter of the Year award for exceptional performance and adherence to quality standards.

- Recognized for consistently meeting or exceeding targets for shearing precision and surface finish.

- Received a Safety Star award for upholding exceptional safety practices in the shearing department.

- Nominated for the Employee Excellence Award for consistently delivering highquality sheared products.

Certificates

- AWS Certified Welder

- CNC Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shear Setter

- Highlight your experience and skills in using different types of shearing machinery.

- Showcase your knowledge of sheet metal layout, blueprint reading, and material handling.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to the specific job you’re applying for, using keywords and phrases from the job description.

- Proofread your resume carefully before submitting it to ensure there are no errors.

Essential Experience Highlights for a Strong Shear Setter Resume

- Interpreted engineering drawings and specifications to determine shearing requirements.

- Set up, calibrated, and operated shear equipment to ensure precise cuts and optimal performance.

- Utilized various shearing techniques, including slitting, notching, and forming, to create complex shapes.

- Inspected and measured cut materials to ensure they met specifications and quality standards.

- Established and maintained a safe and efficient work environment, adhering to safety protocols.

- Trained and supervised junior Shear Setters.

- Collaborated with engineers to develop and refine shearing processes.

Frequently Asked Questions (FAQ’s) For Shear Setter

What is the role of a Shear Setter?

A Shear Setter sets up, operates, and maintains shear machinery to cut and shape metal components according to engineering drawings and specifications.

What skills are required to be a successful Shear Setter?

Successful Shear Setters typically have experience in sheet metal layout, blueprint reading, material handling, punch press operation, and laser cutting.

What are the career prospects for Shear Setters?

Shear Setters with experience and a strong track record can advance to supervisory roles, such as Lead Shear Setter or Production Manager.

How can I prepare for a career as a Shear Setter?

Consider pursuing an Associate’s Degree in Manufacturing Technology or a related field, and gaining practical experience through internships or apprenticeships.

What is the work environment like for Shear Setters?

Shear Setters typically work in industrial settings, such as manufacturing plants or fabrication shops, and may be exposed to noise, dust, and heavy machinery.

How much can I earn as a Shear Setter?

Salaries for Shear Setters can vary depending on experience, location, and employer, but typically range from $30,000 to $60,000 per year.

What are the safety considerations for Shear Setters?

Shear Setters must adhere to strict safety protocols to prevent injuries, such as wearing protective gear, following lockout procedures, and being aware of potential hazards.