Are you a seasoned Sheet Metal Assembler and Riveter (SMAR) seeking a new career path? Discover our professionally built Sheet Metal Assembler and Riveter (SMAR) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

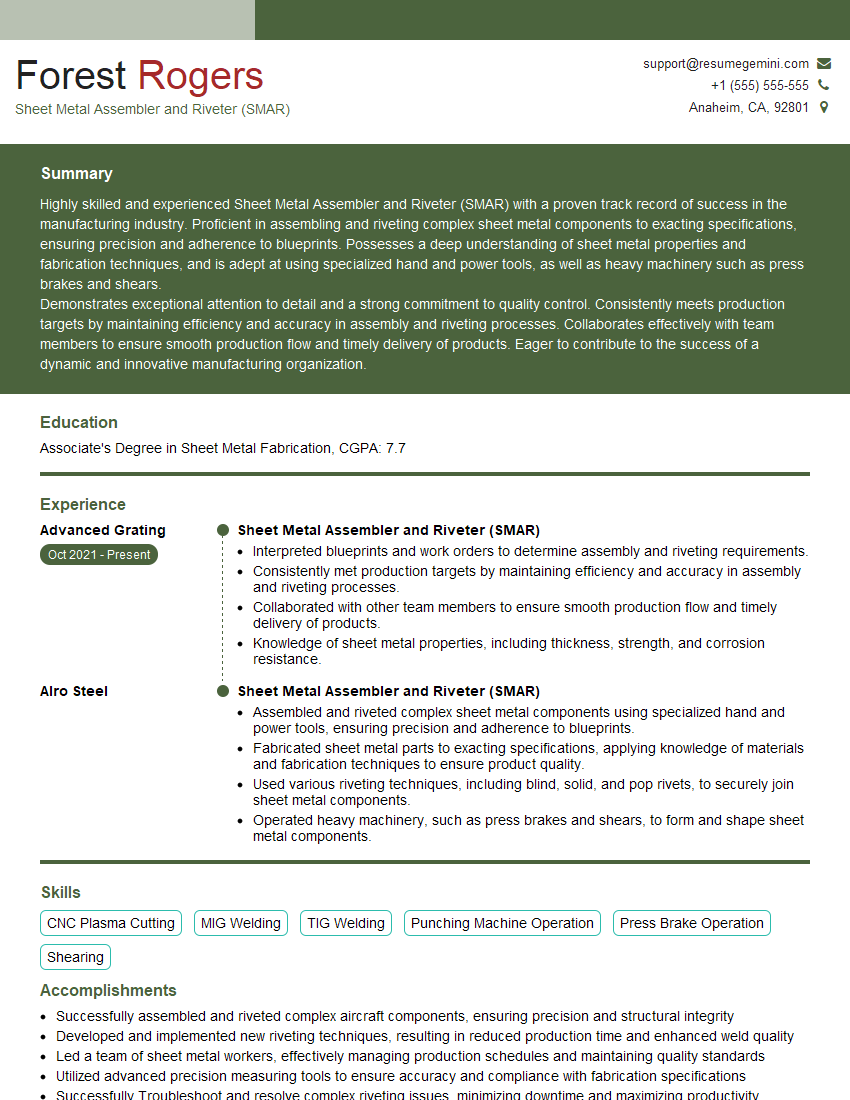

Forest Rogers

Sheet Metal Assembler and Riveter (SMAR)

Summary

Highly skilled and experienced Sheet Metal Assembler and Riveter (SMAR) with a proven track record of success in the manufacturing industry. Proficient in assembling and riveting complex sheet metal components to exacting specifications, ensuring precision and adherence to blueprints. Possesses a deep understanding of sheet metal properties and fabrication techniques, and is adept at using specialized hand and power tools, as well as heavy machinery such as press brakes and shears.

Demonstrates exceptional attention to detail and a strong commitment to quality control. Consistently meets production targets by maintaining efficiency and accuracy in assembly and riveting processes. Collaborates effectively with team members to ensure smooth production flow and timely delivery of products. Eager to contribute to the success of a dynamic and innovative manufacturing organization.

Education

Associate’s Degree in Sheet Metal Fabrication

September 2017

Skills

- CNC Plasma Cutting

- MIG Welding

- TIG Welding

- Punching Machine Operation

- Press Brake Operation

- Shearing

Work Experience

Sheet Metal Assembler and Riveter (SMAR)

- Interpreted blueprints and work orders to determine assembly and riveting requirements.

- Consistently met production targets by maintaining efficiency and accuracy in assembly and riveting processes.

- Collaborated with other team members to ensure smooth production flow and timely delivery of products.

- Knowledge of sheet metal properties, including thickness, strength, and corrosion resistance.

Sheet Metal Assembler and Riveter (SMAR)

- Assembled and riveted complex sheet metal components using specialized hand and power tools, ensuring precision and adherence to blueprints.

- Fabricated sheet metal parts to exacting specifications, applying knowledge of materials and fabrication techniques to ensure product quality.

- Used various riveting techniques, including blind, solid, and pop rivets, to securely join sheet metal components.

- Operated heavy machinery, such as press brakes and shears, to form and shape sheet metal components.

Accomplishments

- Successfully assembled and riveted complex aircraft components, ensuring precision and structural integrity

- Developed and implemented new riveting techniques, resulting in reduced production time and enhanced weld quality

- Led a team of sheet metal workers, effectively managing production schedules and maintaining quality standards

- Utilized advanced precision measuring tools to ensure accuracy and compliance with fabrication specifications

- Successfully Troubleshoot and resolve complex riveting issues, minimizing downtime and maximizing productivity

Awards

- National Award for Excellence in Sheet Metal Fabrication

- Company Recognition for Outstanding Contribution in Riveting Operations

- Industry Achievement Award for Innovative Sheet Metal Assembly Techniques

- Employee of the Month Award for Consistently Exceeding Production Targets

Certificates

- Certified Welder

- AWS Certified Welder

- SMACNA Certified

- OSHA 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Assembler and Riveter (SMAR)

Highlight your skills and experience:

Clearly outline your expertise in sheet metal fabrication, assembly, and riveting techniques. Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate the impact of your work.Showcase your knowledge of materials and equipment:

Emphasize your understanding of different types of sheet metal and the equipment used in fabrication and assembly. This demonstrates your technical proficiency and ability to work with various materials and tools.Demonstrate your quality control capabilities:

Highlight your commitment to precision and quality by describing your experience in adhering to blueprints and meeting industry standards. Mention any certifications or awards you have received for your quality control efforts.Emphasize teamwork and collaboration:

Sheet metal assembly and riveting often involve working with others. Showcase your ability to collaborate effectively within a team environment and contribute to the overall success of the project.Tailor your resume to the job description:

Carefully review the job description and identify the specific skills and qualifications that the employer is seeking. Tailor your resume to highlight the areas where your experience and expertise align with the requirements of the position.

Essential Experience Highlights for a Strong Sheet Metal Assembler and Riveter (SMAR) Resume

- Assembled and riveted complex sheet metal components using specialized hand and power tools, ensuring precision and adherence to blueprints.

- Fabricated sheet metal parts to exacting specifications, applying knowledge of materials and fabrication techniques to ensure product quality.

- Used various riveting techniques, including blind, solid, and pop rivets, to securely join sheet metal components.

- Operated heavy machinery, such as press brakes and shears, to form and shape sheet metal components.

- Interpreted blueprints and work orders to determine assembly and riveting requirements.

- Consistently met production targets by maintaining efficiency and accuracy in assembly and riveting processes.

- Collaborated with other team members to ensure smooth production flow and timely delivery of products.

Frequently Asked Questions (FAQ’s) For Sheet Metal Assembler and Riveter (SMAR)

What is the job outlook for Sheet Metal Assemblers and Riveters?

The job outlook for Sheet Metal Assemblers and Riveters is expected to grow faster than average over the next decade. This is due to the increasing demand for sheet metal products in various industries, such as construction, transportation, and manufacturing.

What are the key skills required to be a successful Sheet Metal Assembler and Riveter?

Key skills for Sheet Metal Assemblers and Riveters include the ability to read and interpret blueprints, operate specialized tools and machinery, and have a strong understanding of sheet metal fabrication techniques.

What is the average salary for a Sheet Metal Assembler and Riveter?

The average salary for a Sheet Metal Assembler and Riveter varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers and Roofers was $49,020 in May 2022.

What are the different types of riveting techniques used by Sheet Metal Assemblers and Riveters?

Sheet Metal Assemblers and Riveters use various riveting techniques, including blind riveting, solid riveting, and pop riveting. Blind riveting is used when access is limited to one side of the joint, while solid riveting is used for permanent and high-strength joints. Pop riveting is a fast and convenient method for joining thin sheets of metal.

What are the advancement opportunities for Sheet Metal Assemblers and Riveters?

With experience and additional training, Sheet Metal Assemblers and Riveters can advance to supervisory roles, such as Lead Assembler or Production Supervisor. They can also specialize in a particular area of sheet metal fabrication, such as welding or finishing.

What is the work environment like for Sheet Metal Assemblers and Riveters?

Sheet Metal Assemblers and Riveters typically work in manufacturing facilities or workshops. The work environment may be noisy and involve exposure to dust and fumes. Safety precautions, such as wearing protective gear and following proper ventilation procedures, are essential.

What is the difference between a Sheet Metal Assembler and a Sheet Metal Fabricator?

Sheet Metal Assemblers focus on assembling and joining sheet metal components, while Sheet Metal Fabricators are involved in the entire process of creating sheet metal products, including cutting, forming, and finishing.

What are some tips for writing a standout Sheet Metal Assembler and Riveter resume?

To write a standout Sheet Metal Assembler and Riveter resume, highlight your skills and experience, quantify your accomplishments, demonstrate your knowledge of sheet metal fabrication techniques, and emphasize your ability to work effectively in a team environment.