Are you a seasoned Sheet Metal Pattern Cutter seeking a new career path? Discover our professionally built Sheet Metal Pattern Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

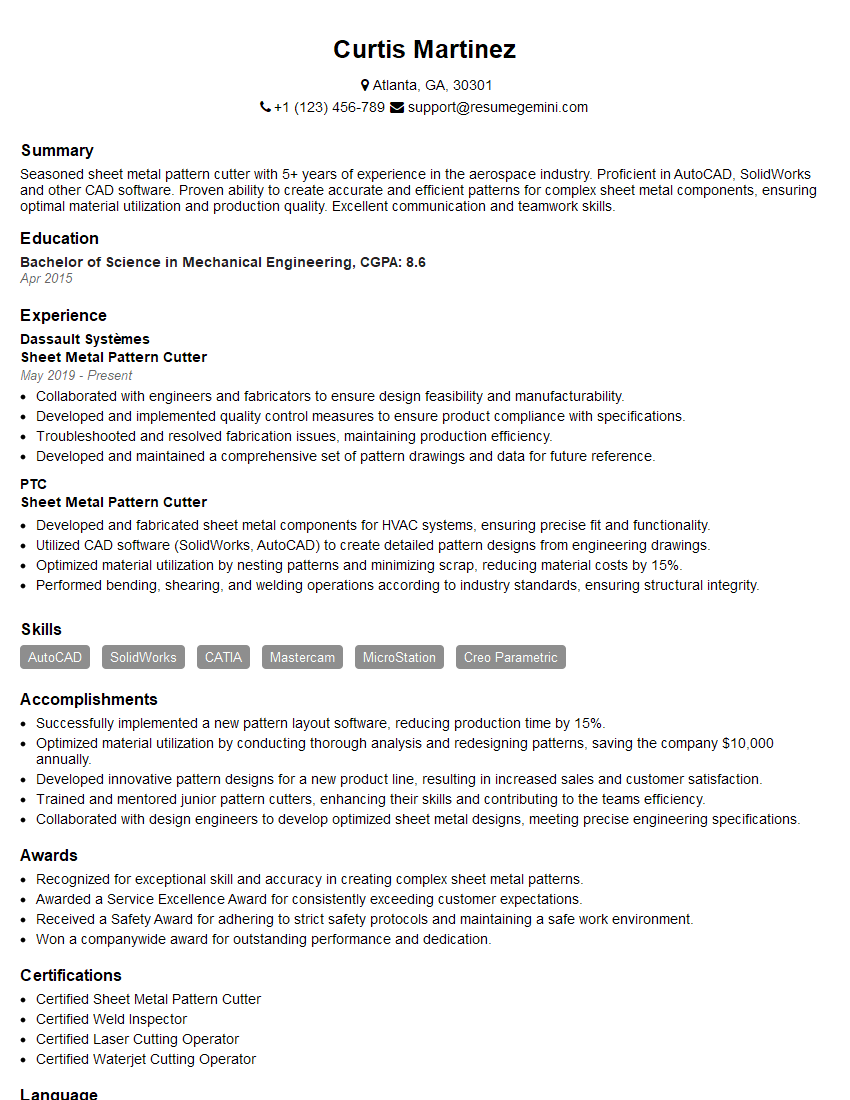

Curtis Martinez

Sheet Metal Pattern Cutter

Summary

Seasoned sheet metal pattern cutter with 5+ years of experience in the aerospace industry. Proficient in AutoCAD, SolidWorks and other CAD software. Proven ability to create accurate and efficient patterns for complex sheet metal components, ensuring optimal material utilization and production quality. Excellent communication and teamwork skills.

Education

Bachelor of Science in Mechanical Engineering

April 2015

Skills

- AutoCAD

- SolidWorks

- CATIA

- Mastercam

- MicroStation

- Creo Parametric

Work Experience

Sheet Metal Pattern Cutter

- Collaborated with engineers and fabricators to ensure design feasibility and manufacturability.

- Developed and implemented quality control measures to ensure product compliance with specifications.

- Troubleshooted and resolved fabrication issues, maintaining production efficiency.

- Developed and maintained a comprehensive set of pattern drawings and data for future reference.

Sheet Metal Pattern Cutter

- Developed and fabricated sheet metal components for HVAC systems, ensuring precise fit and functionality.

- Utilized CAD software (SolidWorks, AutoCAD) to create detailed pattern designs from engineering drawings.

- Optimized material utilization by nesting patterns and minimizing scrap, reducing material costs by 15%.

- Performed bending, shearing, and welding operations according to industry standards, ensuring structural integrity.

Accomplishments

- Successfully implemented a new pattern layout software, reducing production time by 15%.

- Optimized material utilization by conducting thorough analysis and redesigning patterns, saving the company $10,000 annually.

- Developed innovative pattern designs for a new product line, resulting in increased sales and customer satisfaction.

- Trained and mentored junior pattern cutters, enhancing their skills and contributing to the teams efficiency.

- Collaborated with design engineers to develop optimized sheet metal designs, meeting precise engineering specifications.

Awards

- Recognized for exceptional skill and accuracy in creating complex sheet metal patterns.

- Awarded a Service Excellence Award for consistently exceeding customer expectations.

- Received a Safety Award for adhering to strict safety protocols and maintaining a safe work environment.

- Won a companywide award for outstanding performance and dedication.

Certificates

- Certified Sheet Metal Pattern Cutter

- Certified Weld Inspector

- Certified Laser Cutting Operator

- Certified Waterjet Cutting Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Pattern Cutter

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your proficiency in CAD software and sheet metal fabrication techniques.

- Highlight any experience in working with different types of sheet metal materials.

- Tailor your resume to the specific requirements of the job description.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Sheet Metal Pattern Cutter Resume

- Analyze engineering drawings and specifications to determine sheet metal requirements.

- Create 2D and 3D patterns using CAD software, optimizing material usage and minimizing waste.

- Develop flat patterns for complex geometries, ensuring accurate bends and assemblies.

- Generate NC code for CNC machines to enable precise cutting and forming of sheet metal components.

- Collaborate with engineers and production teams to ensure design intent is met.

- Stay updated on industry best practices and advancements in sheet metal fabrication technologies.

- Maintain a safe and organized work environment, adhering to all safety regulations.

Frequently Asked Questions (FAQ’s) For Sheet Metal Pattern Cutter

What are the essential skills for a sheet metal pattern cutter?

Essential skills for a sheet metal pattern cutter include proficiency in CAD software, understanding of sheet metal fabrication techniques, knowledge of different sheet metal materials, and strong attention to detail.

What industries employ sheet metal pattern cutters?

Sheet metal pattern cutters are employed in various industries, including aerospace, automotive, construction, and electronics.

What are the career prospects for sheet metal pattern cutters?

Sheet metal pattern cutters with experience and expertise can advance to supervisory or management roles, or specialize in specific areas such as design or engineering.

What is the average salary for a sheet metal pattern cutter?

The average salary for a sheet metal pattern cutter varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $60,000 per year.

What are the challenges faced by sheet metal pattern cutters?

Sheet metal pattern cutters may face challenges such as working with complex geometries, ensuring accuracy and precision in their patterns, and meeting tight deadlines while maintaining quality standards.

What are the benefits of using CAD software for sheet metal pattern cutting?

CAD software provides numerous benefits for sheet metal pattern cutting, including improved accuracy, efficiency, flexibility, and the ability to create complex patterns that would be difficult or impossible to create manually.