Are you a seasoned Sheet Roller Operator seeking a new career path? Discover our professionally built Sheet Roller Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

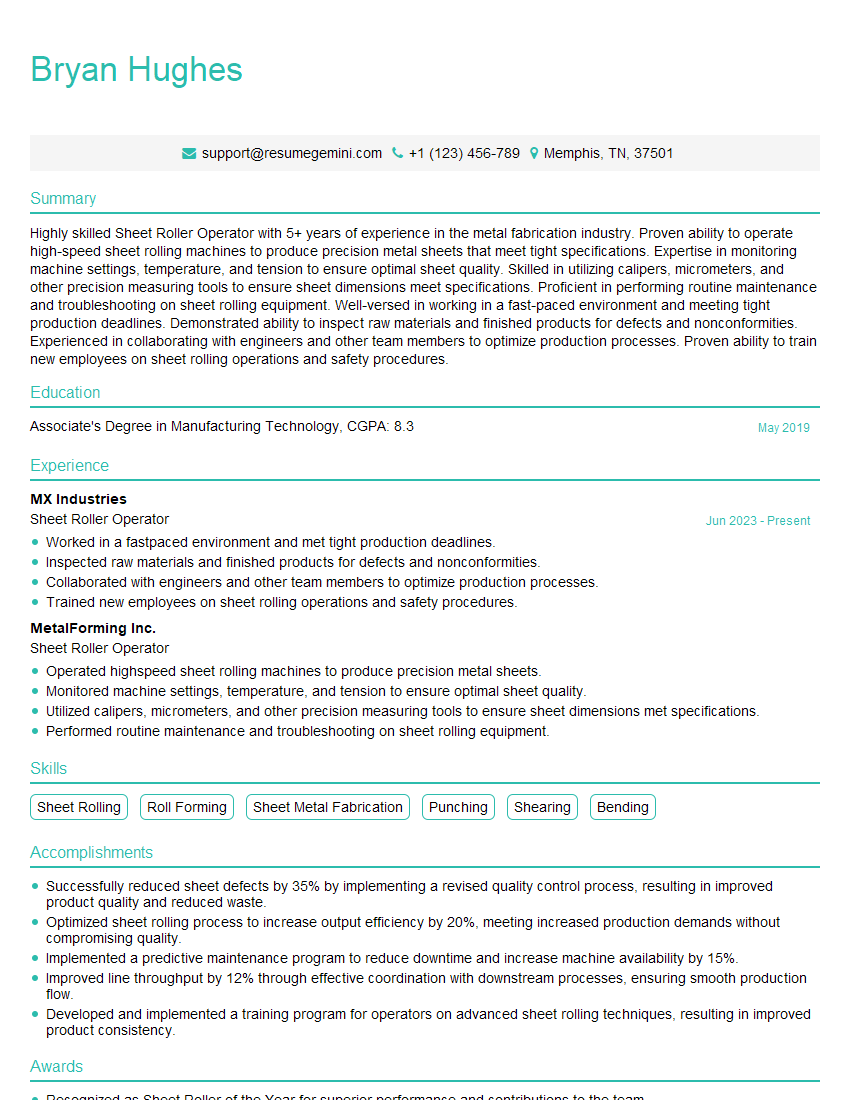

Bryan Hughes

Sheet Roller Operator

Summary

Highly skilled Sheet Roller Operator with 5+ years of experience in the metal fabrication industry. Proven ability to operate high-speed sheet rolling machines to produce precision metal sheets that meet tight specifications. Expertise in monitoring machine settings, temperature, and tension to ensure optimal sheet quality. Skilled in utilizing calipers, micrometers, and other precision measuring tools to ensure sheet dimensions meet specifications. Proficient in performing routine maintenance and troubleshooting on sheet rolling equipment. Well-versed in working in a fast-paced environment and meeting tight production deadlines. Demonstrated ability to inspect raw materials and finished products for defects and nonconformities. Experienced in collaborating with engineers and other team members to optimize production processes. Proven ability to train new employees on sheet rolling operations and safety procedures.

Education

Associate’s Degree in Manufacturing Technology

May 2019

Skills

- Sheet Rolling

- Roll Forming

- Sheet Metal Fabrication

- Punching

- Shearing

- Bending

Work Experience

Sheet Roller Operator

- Worked in a fastpaced environment and met tight production deadlines.

- Inspected raw materials and finished products for defects and nonconformities.

- Collaborated with engineers and other team members to optimize production processes.

- Trained new employees on sheet rolling operations and safety procedures.

Sheet Roller Operator

- Operated highspeed sheet rolling machines to produce precision metal sheets.

- Monitored machine settings, temperature, and tension to ensure optimal sheet quality.

- Utilized calipers, micrometers, and other precision measuring tools to ensure sheet dimensions met specifications.

- Performed routine maintenance and troubleshooting on sheet rolling equipment.

Accomplishments

- Successfully reduced sheet defects by 35% by implementing a revised quality control process, resulting in improved product quality and reduced waste.

- Optimized sheet rolling process to increase output efficiency by 20%, meeting increased production demands without compromising quality.

- Implemented a predictive maintenance program to reduce downtime and increase machine availability by 15%.

- Improved line throughput by 12% through effective coordination with downstream processes, ensuring smooth production flow.

- Developed and implemented a training program for operators on advanced sheet rolling techniques, resulting in improved product consistency.

Awards

- Recognized as Sheet Roller of the Year for superior performance and contributions to the team.

- Awarded Safety Excellence Award for consistent compliance and adherence to safety protocols.

- Received Employee of the Quarter recognition for exceptional contributions to the production team.

- Honored with Innovative Idea Award for developing a novel method to improve sheet handling efficiency.

Certificates

- Certified Sheet Metal Fabricator

- Certified Welder

- Certified Machinist

- Certified Quality Control Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Roller Operator

- Highlight your experience operating high-speed sheet rolling machines and producing precision metal sheets.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Demonstrate your knowledge of sheet rolling processes and industry best practices.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors.

- Tailor your resume to each job you apply for, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Sheet Roller Operator Resume

- Operate high-speed sheet rolling machines to produce precision metal sheets.

- Monitor machine settings, temperature, and tension to ensure optimal sheet quality.

- Utilize calipers, micrometers, and other precision measuring tools to ensure sheet dimensions meet specifications.

- Perform routine maintenance and troubleshooting on sheet rolling equipment.

- Work in a fast-paced environment and meet tight production deadlines.

- Inspect raw materials and finished products for defects and nonconformities.

- Collaborate with engineers and other team members to optimize production processes.

- Train new employees on sheet rolling operations and safety procedures.

Frequently Asked Questions (FAQ’s) For Sheet Roller Operator

What is a Sheet Roller Operator?

A Sheet Roller Operator is responsible for operating high-speed sheet rolling machines to produce precision metal sheets. They monitor machine settings, temperature, and tension to ensure optimal sheet quality. They also utilize calipers, micrometers, and other precision measuring tools to ensure sheet dimensions meet specifications.

What are the key skills required to be a successful Sheet Roller Operator?

The key skills required to be a successful Sheet Roller Operator include the ability to operate high-speed sheet rolling machines, monitor machine settings, temperature, and tension, utilize calipers, micrometers, and other precision measuring tools, perform routine maintenance and troubleshooting on sheet rolling equipment, work in a fast-paced environment and meet tight production deadlines, inspect raw materials and finished products for defects and nonconformities, and collaborate with engineers and other team members to optimize production processes.

What are the job prospects for Sheet Roller Operators?

The job prospects for Sheet Roller Operators are expected to be good over the next few years. The demand for precision metal sheets is expected to grow as the manufacturing industry continues to expand. As a result, there will be a need for skilled Sheet Roller Operators to operate the machines that produce these sheets.

What is the average salary for a Sheet Roller Operator?

The average salary for a Sheet Roller Operator is around $25,000 per year. However, salaries can vary depending on experience, location, and company size.

What are the benefits of working as a Sheet Roller Operator?

The benefits of working as a Sheet Roller Operator include the opportunity to work with cutting-edge technology, the chance to make a difference in the manufacturing industry, and the potential for career advancement.

What are the challenges of working as a Sheet Roller Operator?

The challenges of working as a Sheet Roller Operator include the need to work in a fast-paced environment, the potential for repetitive work, and the need to be able to work with precision.

How can I become a Sheet Roller Operator?

To become a Sheet Roller Operator, you typically need a high school diploma or equivalent. You may also need to complete a training program in sheet rolling. Some employers may also require experience operating high-speed sheet rolling machines.