Are you a seasoned Shell Mold Bonding Machine Operator seeking a new career path? Discover our professionally built Shell Mold Bonding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

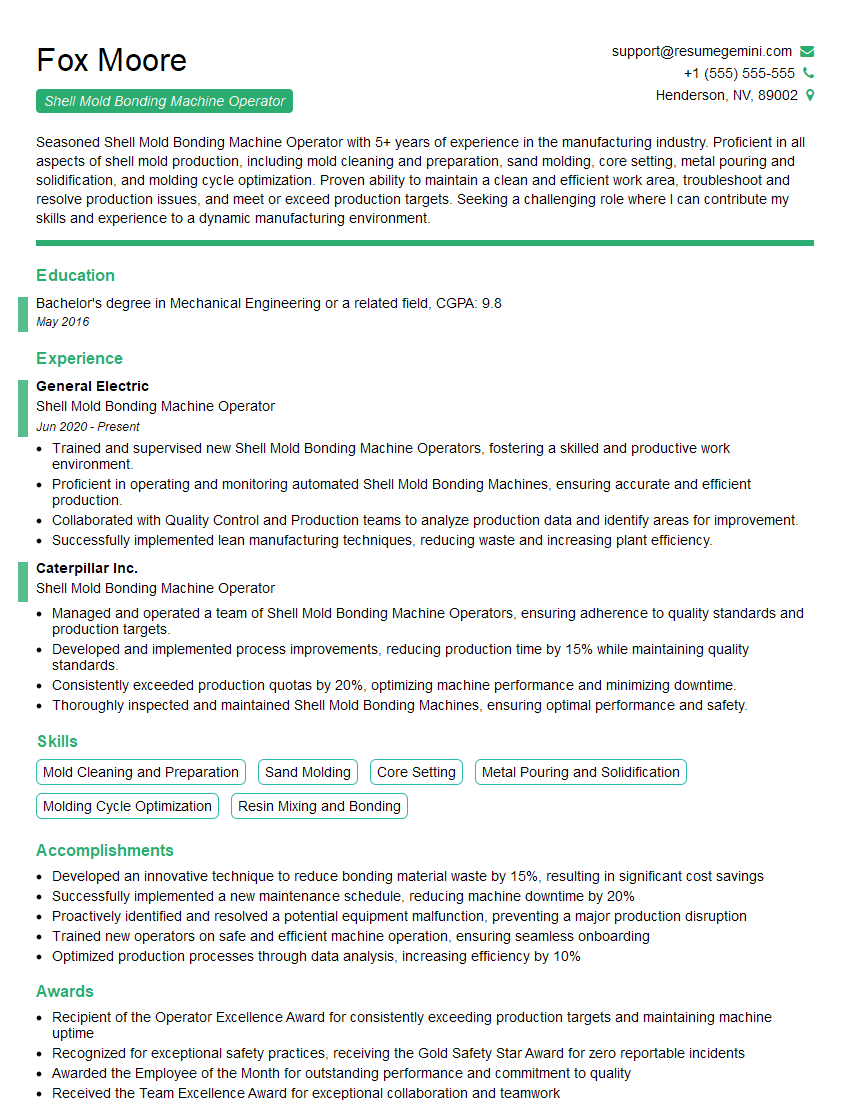

Fox Moore

Shell Mold Bonding Machine Operator

Summary

Seasoned Shell Mold Bonding Machine Operator with 5+ years of experience in the manufacturing industry. Proficient in all aspects of shell mold production, including mold cleaning and preparation, sand molding, core setting, metal pouring and solidification, and molding cycle optimization. Proven ability to maintain a clean and efficient work area, troubleshoot and resolve production issues, and meet or exceed production targets. Seeking a challenging role where I can contribute my skills and experience to a dynamic manufacturing environment.

Education

Bachelor’s degree in Mechanical Engineering or a related field

May 2016

Skills

- Mold Cleaning and Preparation

- Sand Molding

- Core Setting

- Metal Pouring and Solidification

- Molding Cycle Optimization

- Resin Mixing and Bonding

Work Experience

Shell Mold Bonding Machine Operator

- Trained and supervised new Shell Mold Bonding Machine Operators, fostering a skilled and productive work environment.

- Proficient in operating and monitoring automated Shell Mold Bonding Machines, ensuring accurate and efficient production.

- Collaborated with Quality Control and Production teams to analyze production data and identify areas for improvement.

- Successfully implemented lean manufacturing techniques, reducing waste and increasing plant efficiency.

Shell Mold Bonding Machine Operator

- Managed and operated a team of Shell Mold Bonding Machine Operators, ensuring adherence to quality standards and production targets.

- Developed and implemented process improvements, reducing production time by 15% while maintaining quality standards.

- Consistently exceeded production quotas by 20%, optimizing machine performance and minimizing downtime.

- Thoroughly inspected and maintained Shell Mold Bonding Machines, ensuring optimal performance and safety.

Accomplishments

- Developed an innovative technique to reduce bonding material waste by 15%, resulting in significant cost savings

- Successfully implemented a new maintenance schedule, reducing machine downtime by 20%

- Proactively identified and resolved a potential equipment malfunction, preventing a major production disruption

- Trained new operators on safe and efficient machine operation, ensuring seamless onboarding

- Optimized production processes through data analysis, increasing efficiency by 10%

Awards

- Recipient of the Operator Excellence Award for consistently exceeding production targets and maintaining machine uptime

- Recognized for exceptional safety practices, receiving the Gold Safety Star Award for zero reportable incidents

- Awarded the Employee of the Month for outstanding performance and commitment to quality

- Received the Team Excellence Award for exceptional collaboration and teamwork

Certificates

- American Foundry Society (AFS) Certified Shell Molding Technician

- National Institute for Metalworking Skills (NIMS)

- Occupational Safety and Health Administration (OSHA) 30-Hour General Industry Safety Certification

- American Society for Quality (ASQ) Certified Quality Technician (CQT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shell Mold Bonding Machine Operator

- Highlight your experience and skills in operating shell mold bonding machines.

- Quantify your accomplishments with specific metrics, such as the number of molds produced or the percentage of defects reduced.

- Demonstrate your knowledge of the bonding process and your ability to troubleshoot and resolve issues.

- Emphasize your commitment to safety and quality control.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Shell Mold Bonding Machine Operator Resume

- Set up and operate shell mold bonding machines to produce high-quality molds

- Prepare mold surfaces, apply release agents, and perform other mold preparation tasks

- Mix and prepare resin and bonding materials according to specified formulations

- Monitor bonding process and make adjustments as needed to ensure proper bonding

- Inspect finished molds for defects and ensure they meet quality standards

- Maintain a clean and organized work area and adhere to safety protocols

- Troubleshoot and resolve production issues to minimize downtime

Frequently Asked Questions (FAQ’s) For Shell Mold Bonding Machine Operator

What is the role of a Shell Mold Bonding Machine Operator?

A Shell Mold Bonding Machine Operator is responsible for operating and maintaining shell mold bonding machines, which are used to produce molds for metal castings. They prepare mold surfaces, mix and apply bonding materials, and monitor the bonding process to ensure the production of high-quality molds.

What are the key skills required for a Shell Mold Bonding Machine Operator?

Key skills for a Shell Mold Bonding Machine Operator include the ability to operate and maintain shell mold bonding machines, knowledge of the bonding process, experience in mold preparation and inspection, and a commitment to safety and quality control.

What are the career prospects for a Shell Mold Bonding Machine Operator?

Shell Mold Bonding Machine Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They may also specialize in a particular area of shell mold bonding, such as mold design or process optimization.

What are the challenges faced by a Shell Mold Bonding Machine Operator?

Shell Mold Bonding Machine Operators may face challenges such as working in a fast-paced environment, meeting production targets, and ensuring the quality of their work. They may also need to troubleshoot and resolve production issues.

What are the safety precautions that a Shell Mold Bonding Machine Operator should take?

Shell Mold Bonding Machine Operators should wear appropriate safety gear, such as gloves, safety glasses, and a respirator, when operating machines or handling chemicals. They should also be aware of the potential hazards of the bonding process and take steps to minimize risks.

What are the industry trends that are impacting the role of a Shell Mold Bonding Machine Operator?

The manufacturing industry is increasingly adopting automation and digital technologies, which is impacting the role of Shell Mold Bonding Machine Operators. They may need to develop new skills to work with automated systems and to interpret data from sensors and other monitoring devices.

What are the certifications that are available for a Shell Mold Bonding Machine Operator?

There are several certifications available for Shell Mold Bonding Machine Operators, such as the Certified Shell Mold Bonding Machine Operator certification offered by the American Foundry Society.