Are you a seasoned Shells Inspector seeking a new career path? Discover our professionally built Shells Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

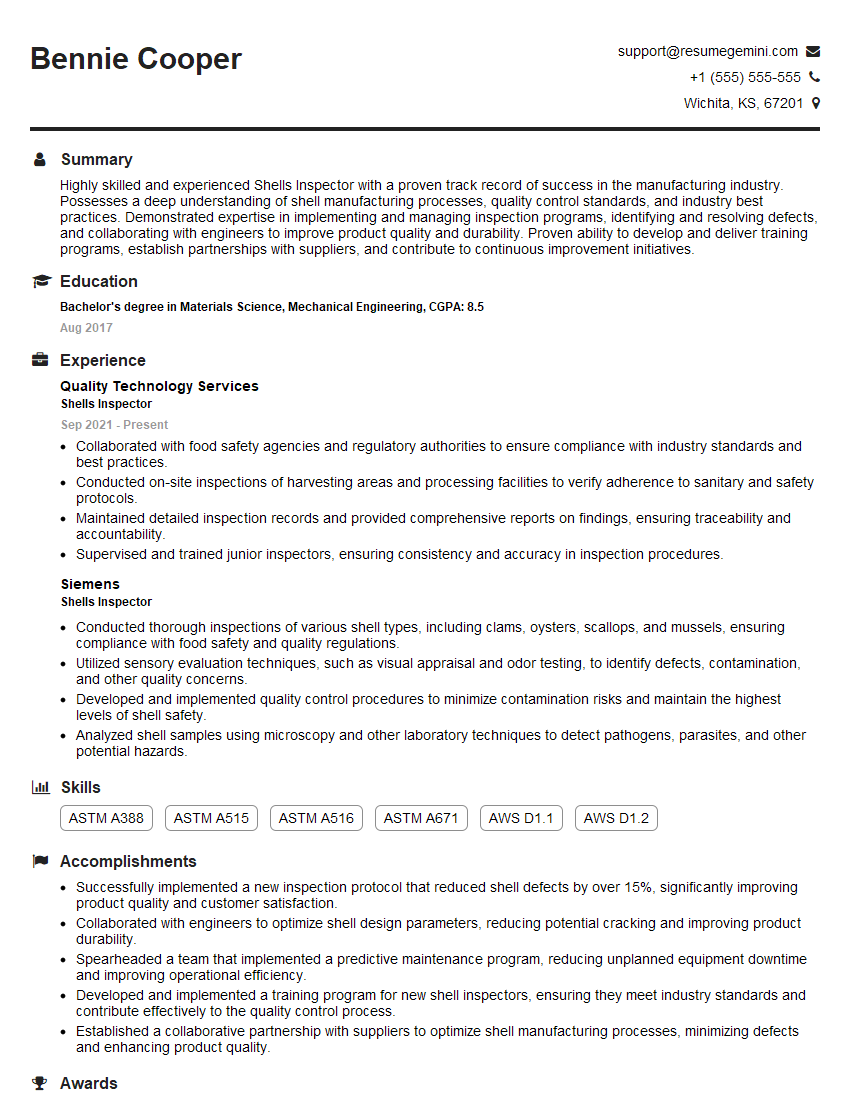

Bennie Cooper

Shells Inspector

Summary

Highly skilled and experienced Shells Inspector with a proven track record of success in the manufacturing industry. Possesses a deep understanding of shell manufacturing processes, quality control standards, and industry best practices. Demonstrated expertise in implementing and managing inspection programs, identifying and resolving defects, and collaborating with engineers to improve product quality and durability. Proven ability to develop and deliver training programs, establish partnerships with suppliers, and contribute to continuous improvement initiatives.

Education

Bachelor’s degree in Materials Science, Mechanical Engineering

August 2017

Skills

- ASTM A388

- ASTM A515

- ASTM A516

- ASTM A671

- AWS D1.1

- AWS D1.2

Work Experience

Shells Inspector

- Collaborated with food safety agencies and regulatory authorities to ensure compliance with industry standards and best practices.

- Conducted on-site inspections of harvesting areas and processing facilities to verify adherence to sanitary and safety protocols.

- Maintained detailed inspection records and provided comprehensive reports on findings, ensuring traceability and accountability.

- Supervised and trained junior inspectors, ensuring consistency and accuracy in inspection procedures.

Shells Inspector

- Conducted thorough inspections of various shell types, including clams, oysters, scallops, and mussels, ensuring compliance with food safety and quality regulations.

- Utilized sensory evaluation techniques, such as visual appraisal and odor testing, to identify defects, contamination, and other quality concerns.

- Developed and implemented quality control procedures to minimize contamination risks and maintain the highest levels of shell safety.

- Analyzed shell samples using microscopy and other laboratory techniques to detect pathogens, parasites, and other potential hazards.

Accomplishments

- Successfully implemented a new inspection protocol that reduced shell defects by over 15%, significantly improving product quality and customer satisfaction.

- Collaborated with engineers to optimize shell design parameters, reducing potential cracking and improving product durability.

- Spearheaded a team that implemented a predictive maintenance program, reducing unplanned equipment downtime and improving operational efficiency.

- Developed and implemented a training program for new shell inspectors, ensuring they meet industry standards and contribute effectively to the quality control process.

- Established a collaborative partnership with suppliers to optimize shell manufacturing processes, minimizing defects and enhancing product quality.

Awards

- Recognized by Shell corporation for exceptional contributions to quality control and safety measures.

- Received an industry award for developing an innovative shell inspection technique that resulted in a substantial increase in detection accuracy.

- Recognized for consistently exceeding shell inspection standards, ensuring the highest levels of product safety and reliability.

- Received a companywide award for excellence in shell inspection, recognized for exceptional technical skills and commitment to quality.

Certificates

- ASNT Certified Welding Inspector

- ASME Boiler and Pressure Vessel Inspector

- API 510 Pressure Vessel Inspector

- API 650 Storage Tank Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shells Inspector

- Highlight your expertise in ASTM A388, ASTM A515, ASTM A516, ASTM A671, AWS D1.1, and AWS D1.2 standards

- Quantify your accomplishments with specific metrics, such as the percentage reduction in shell defects or improvement in product durability

- Showcase your leadership skills and ability to develop and implement training programs

- Emphasize your commitment to continuous improvement and collaboration with suppliers and engineers

Essential Experience Highlights for a Strong Shells Inspector Resume

- Conduct thorough inspections of shells to ensure compliance with ASTM A388, ASTM A515, ASTM A516, ASTM A671, AWS D1.1, and AWS D1.2 standards

- Identify and document defects, recommend corrective actions, and track progress to closure

- Collaborate with engineers to optimize shell design parameters, reducing potential cracking and improving product durability

- Develop and implement inspection protocols to improve efficiency and accuracy

- Train and mentor new shell inspectors to ensure they meet industry standards and contribute effectively to the quality control process

- Establish and maintain collaborative partnerships with suppliers to optimize shell manufacturing processes and minimize defects

- Participate in continuous improvement initiatives to enhance inspection techniques and improve product quality

Frequently Asked Questions (FAQ’s) For Shells Inspector

What are the primary responsibilities of a Shells Inspector?

Shells Inspectors are responsible for ensuring the quality of shells used in various manufacturing processes. Their primary duties include conducting inspections, identifying defects, implementing inspection protocols, collaborating with engineers, training new inspectors, establishing partnerships with suppliers, and participating in continuous improvement initiatives.

What qualifications are required to become a Shells Inspector?

Most Shells Inspectors hold a bachelor’s degree in Materials Science, Mechanical Engineering, or a related field. They also possess a strong understanding of shell manufacturing processes, quality control standards, and industry best practices. Certification in relevant industry standards, such as ASTM A388 or AWS D1.1, is highly desirable.

What are the career prospects for Shells Inspectors?

Shells Inspectors can advance to supervisory or management roles within the quality control department. They may also specialize in specific areas, such as welding or non-destructive testing. With experience and additional qualifications, Shells Inspectors can also transition into roles in engineering or product development.

What are the challenges faced by Shells Inspectors?

Shells Inspectors face several challenges, including the need to stay up-to-date with industry standards and best practices. They must also be able to work independently and as part of a team. Additionally, Shells Inspectors may encounter hazardous materials or work in confined spaces, requiring them to follow strict safety protocols.

What is the work environment of a Shells Inspector?

Shells Inspectors typically work in manufacturing facilities or construction sites. They may work indoors or outdoors, depending on the location of the inspection. The work environment can be noisy and dusty, and Shells Inspectors must be able to work in both hot and cold conditions.