Are you a seasoned Shot Blaster seeking a new career path? Discover our professionally built Shot Blaster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

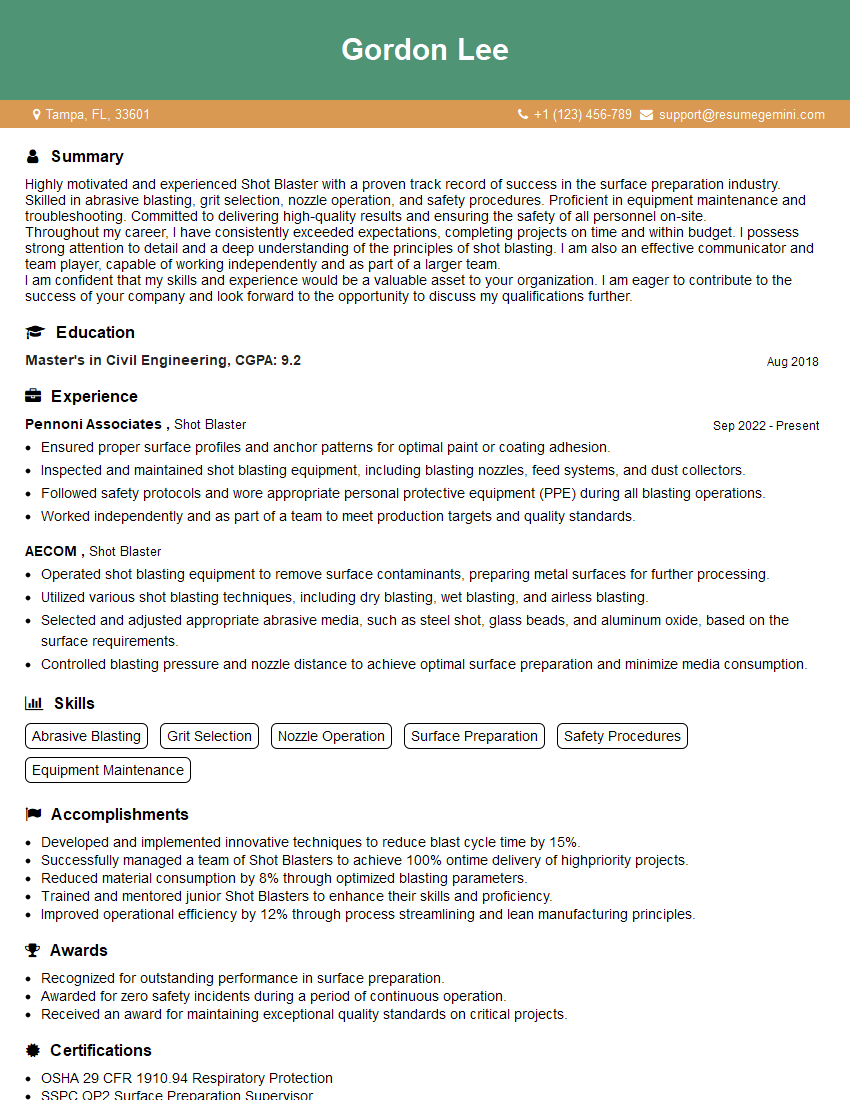

Gordon Lee

Shot Blaster

Summary

Highly motivated and experienced Shot Blaster with a proven track record of success in the surface preparation industry. Skilled in abrasive blasting, grit selection, nozzle operation, and safety procedures. Proficient in equipment maintenance and troubleshooting. Committed to delivering high-quality results and ensuring the safety of all personnel on-site.

Throughout my career, I have consistently exceeded expectations, completing projects on time and within budget. I possess strong attention to detail and a deep understanding of the principles of shot blasting. I am also an effective communicator and team player, capable of working independently and as part of a larger team.

I am confident that my skills and experience would be a valuable asset to your organization. I am eager to contribute to the success of your company and look forward to the opportunity to discuss my qualifications further.

Education

Master’s in Civil Engineering

August 2018

Skills

- Abrasive Blasting

- Grit Selection

- Nozzle Operation

- Surface Preparation

- Safety Procedures

- Equipment Maintenance

Work Experience

Shot Blaster

- Ensured proper surface profiles and anchor patterns for optimal paint or coating adhesion.

- Inspected and maintained shot blasting equipment, including blasting nozzles, feed systems, and dust collectors.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) during all blasting operations.

- Worked independently and as part of a team to meet production targets and quality standards.

Shot Blaster

- Operated shot blasting equipment to remove surface contaminants, preparing metal surfaces for further processing.

- Utilized various shot blasting techniques, including dry blasting, wet blasting, and airless blasting.

- Selected and adjusted appropriate abrasive media, such as steel shot, glass beads, and aluminum oxide, based on the surface requirements.

- Controlled blasting pressure and nozzle distance to achieve optimal surface preparation and minimize media consumption.

Accomplishments

- Developed and implemented innovative techniques to reduce blast cycle time by 15%.

- Successfully managed a team of Shot Blasters to achieve 100% ontime delivery of highpriority projects.

- Reduced material consumption by 8% through optimized blasting parameters.

- Trained and mentored junior Shot Blasters to enhance their skills and proficiency.

- Improved operational efficiency by 12% through process streamlining and lean manufacturing principles.

Awards

- Recognized for outstanding performance in surface preparation.

- Awarded for zero safety incidents during a period of continuous operation.

- Received an award for maintaining exceptional quality standards on critical projects.

Certificates

- OSHA 29 CFR 1910.94 Respiratory Protection

- SSPC QP2 Surface Preparation Supervisor

- NACE CIP Level 1 Protective Coatings Inspector

- AWS CWI Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shot Blaster

- Highlight your experience and skills in abrasive blasting, grit selection, and nozzle operation.

- Showcase your knowledge of safety procedures and equipment maintenance.

- Provide specific examples of projects where you have successfully prepared surfaces for coating, painting, or other treatments.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

Essential Experience Highlights for a Strong Shot Blaster Resume

- Prepare surfaces for coating, painting, or other treatments using abrasive blasting techniques.

- Select appropriate abrasives and nozzles based on the surface material and desired finish.

- Operate shot blasting equipment safely and efficiently, following established safety procedures.

- Maintain and troubleshoot shot blasting equipment to ensure optimal performance.

- Inspect blasted surfaces to ensure they meet the required standards.

- Dispose of spent abrasive materials in accordance with environmental regulations.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Shot Blaster

What are the primary responsibilities of a Shot Blaster?

Shot Blasters are responsible for preparing surfaces for coating, painting, or other treatments using abrasive blasting techniques. They select appropriate abrasives and nozzles based on the surface material and desired finish, and operate shot blasting equipment safely and efficiently. Shot Blasters also maintain and troubleshoot equipment, inspect blasted surfaces, and dispose of spent abrasive materials.

What are the key skills required to be a successful Shot Blaster?

Successful Shot Blasters possess a strong understanding of abrasive blasting techniques, safety procedures, and equipment maintenance. They are also proficient in grit selection and nozzle operation. Additionally, Shot Blasters should have strong attention to detail and be able to work independently and as part of a team.

What are the career prospects for Shot Blasters?

Shot Blasters can advance their careers by gaining experience and developing new skills. They may move into supervisory roles or become certified in specialized areas of shot blasting. With additional education and training, Shot Blasters can also pursue careers in quality control or engineering.

What are the safety precautions that Shot Blasters must follow?

Shot Blasters must follow strict safety procedures to protect themselves and others from the hazards associated with abrasive blasting. These precautions include wearing appropriate personal protective equipment, using proper ventilation, and following established operating procedures. Shot Blasters must also be aware of the potential for fire and explosion, and take steps to prevent these hazards.

What are the environmental regulations that Shot Blasters must comply with?

Shot Blasters must comply with environmental regulations regarding the disposal of spent abrasive materials. These regulations vary by jurisdiction, but generally require that spent abrasives be disposed of in a manner that minimizes the potential for environmental harm.