Are you a seasoned Shot Peening Operator seeking a new career path? Discover our professionally built Shot Peening Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

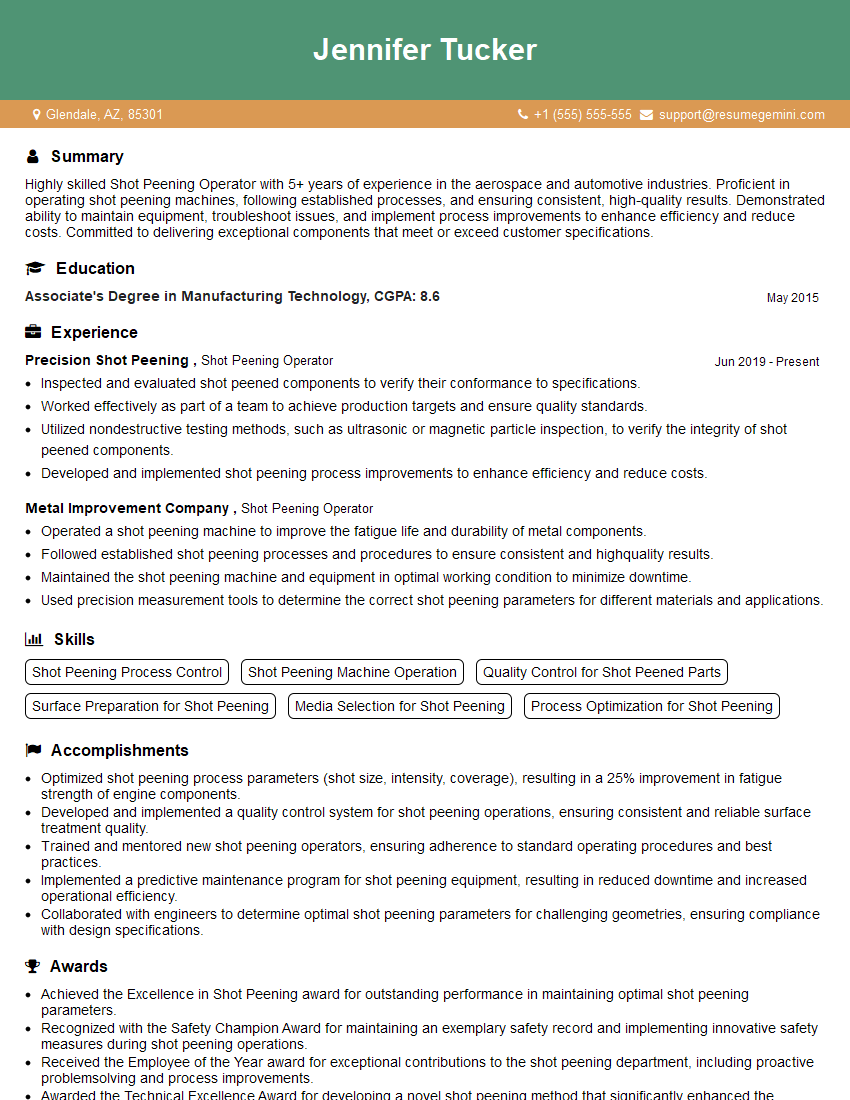

Jennifer Tucker

Shot Peening Operator

Summary

Highly skilled Shot Peening Operator with 5+ years of experience in the aerospace and automotive industries. Proficient in operating shot peening machines, following established processes, and ensuring consistent, high-quality results. Demonstrated ability to maintain equipment, troubleshoot issues, and implement process improvements to enhance efficiency and reduce costs. Committed to delivering exceptional components that meet or exceed customer specifications.

Education

Associate’s Degree in Manufacturing Technology

May 2015

Skills

- Shot Peening Process Control

- Shot Peening Machine Operation

- Quality Control for Shot Peened Parts

- Surface Preparation for Shot Peening

- Media Selection for Shot Peening

- Process Optimization for Shot Peening

Work Experience

Shot Peening Operator

- Inspected and evaluated shot peened components to verify their conformance to specifications.

- Worked effectively as part of a team to achieve production targets and ensure quality standards.

- Utilized nondestructive testing methods, such as ultrasonic or magnetic particle inspection, to verify the integrity of shot peened components.

- Developed and implemented shot peening process improvements to enhance efficiency and reduce costs.

Shot Peening Operator

- Operated a shot peening machine to improve the fatigue life and durability of metal components.

- Followed established shot peening processes and procedures to ensure consistent and highquality results.

- Maintained the shot peening machine and equipment in optimal working condition to minimize downtime.

- Used precision measurement tools to determine the correct shot peening parameters for different materials and applications.

Accomplishments

- Optimized shot peening process parameters (shot size, intensity, coverage), resulting in a 25% improvement in fatigue strength of engine components.

- Developed and implemented a quality control system for shot peening operations, ensuring consistent and reliable surface treatment quality.

- Trained and mentored new shot peening operators, ensuring adherence to standard operating procedures and best practices.

- Implemented a predictive maintenance program for shot peening equipment, resulting in reduced downtime and increased operational efficiency.

- Collaborated with engineers to determine optimal shot peening parameters for challenging geometries, ensuring compliance with design specifications.

Awards

- Achieved the Excellence in Shot Peening award for outstanding performance in maintaining optimal shot peening parameters.

- Recognized with the Safety Champion Award for maintaining an exemplary safety record and implementing innovative safety measures during shot peening operations.

- Received the Employee of the Year award for exceptional contributions to the shot peening department, including proactive problemsolving and process improvements.

- Awarded the Technical Excellence Award for developing a novel shot peening method that significantly enhanced the durability of aircraft landing gear components.

Certificates

- Certified Shot Peening Operator (CSPO)

- Nadcap Accredited Shot Peener

- ASME Boiler and Pressure Vessel Code Endorsement for Shot Peening

- SAE Aerospace Standard AS5242 Certification for Shot Peening

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Shot Peening Operator

- Highlight your experience and expertise in shot peening operations and quality control

- Quantify your accomplishments using specific metrics whenever possible

- Showcase your knowledge of shot peening processes, equipment, and industry standards

- Tailor your resume to the specific requirements of the job you are applying for

Essential Experience Highlights for a Strong Shot Peening Operator Resume

- Operate shot peening machines to improve the fatigue life and durability of metal components

- Follow established shot peening processes and procedures to ensure consistent and high-quality results

- Maintain the shot peening machine and equipment in optimal working condition to minimize downtime

- Use precision measurement tools to determine the correct shot peening parameters for different materials and applications

- Inspect and evaluate shot peened components to verify their conformance to specifications

- Work effectively as part of a team to achieve production targets and ensure quality standards

- Utilize nondestructive testing methods, such as ultrasonic or magnetic particle inspection, to verify the integrity of shot peened components

Frequently Asked Questions (FAQ’s) For Shot Peening Operator

What is shot peening?

Shot peening is a cold working process that improves the fatigue life and durability of metal components by introducing compressive residual stresses on the surface.

What are the benefits of shot peening?

Shot peening can increase the fatigue life of metal components by up to 10 times, improve their resistance to stress corrosion cracking, and reduce the risk of surface defects.

What materials can be shot peened?

Shot peening can be used on a wide variety of materials, including metals, plastics, and composites.

What are the different types of shot peening machines?

There are two main types of shot peening machines: air blast and wheel blast.

What are the different types of shot media used in shot peening?

The most common types of shot media used in shot peening are steel shot, glass beads, and ceramic beads.

What are the safety precautions that should be taken when shot peening?

Shot peening can generate dust and noise, so it is important to wear appropriate personal protective equipment, such as respirators and earplugs.