Are you a seasoned Skelp Processor seeking a new career path? Discover our professionally built Skelp Processor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

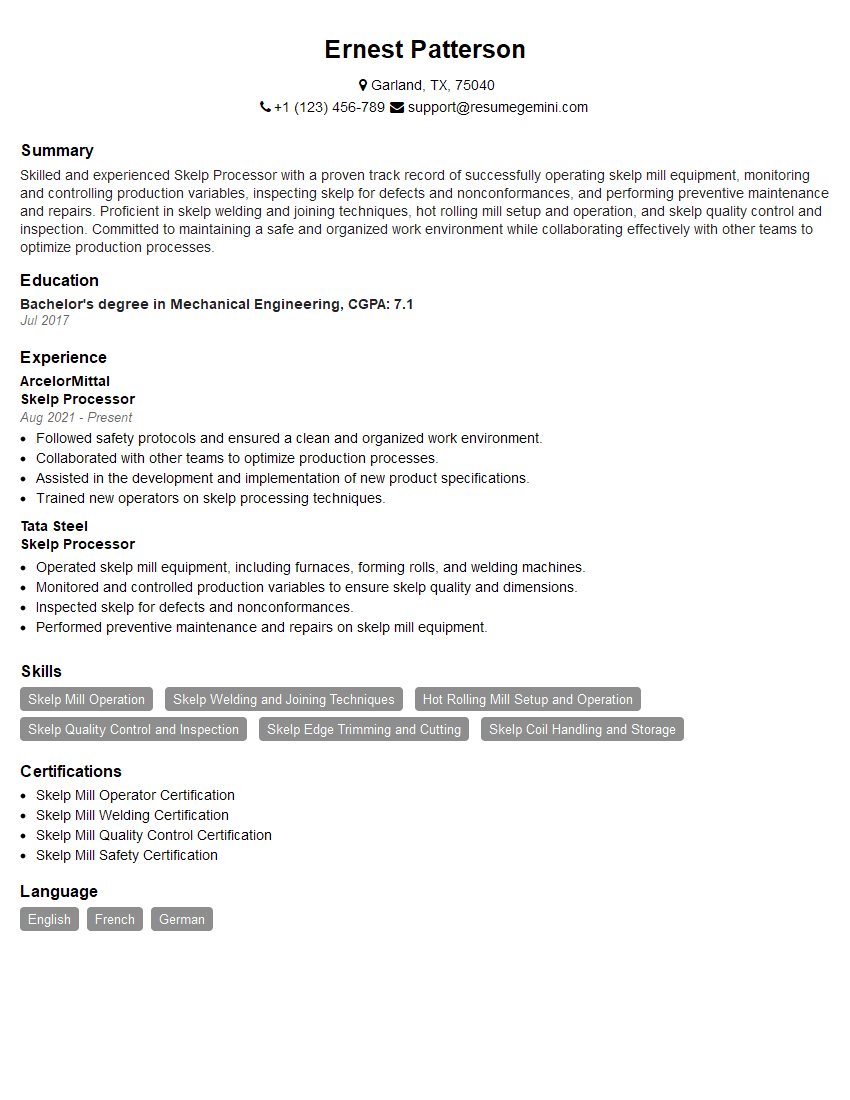

Ernest Patterson

Skelp Processor

Summary

Skilled and experienced Skelp Processor with a proven track record of successfully operating skelp mill equipment, monitoring and controlling production variables, inspecting skelp for defects and nonconformances, and performing preventive maintenance and repairs. Proficient in skelp welding and joining techniques, hot rolling mill setup and operation, and skelp quality control and inspection. Committed to maintaining a safe and organized work environment while collaborating effectively with other teams to optimize production processes.

Education

Bachelor’s degree in Mechanical Engineering

July 2017

Skills

- Skelp Mill Operation

- Skelp Welding and Joining Techniques

- Hot Rolling Mill Setup and Operation

- Skelp Quality Control and Inspection

- Skelp Edge Trimming and Cutting

- Skelp Coil Handling and Storage

Work Experience

Skelp Processor

- Followed safety protocols and ensured a clean and organized work environment.

- Collaborated with other teams to optimize production processes.

- Assisted in the development and implementation of new product specifications.

- Trained new operators on skelp processing techniques.

Skelp Processor

- Operated skelp mill equipment, including furnaces, forming rolls, and welding machines.

- Monitored and controlled production variables to ensure skelp quality and dimensions.

- Inspected skelp for defects and nonconformances.

- Performed preventive maintenance and repairs on skelp mill equipment.

Certificates

- Skelp Mill Operator Certification

- Skelp Mill Welding Certification

- Skelp Mill Quality Control Certification

- Skelp Mill Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Skelp Processor

- Highlight your experience and skills in operating skelp mill equipment and producing skelp to specification.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and quality.

- Emphasize your knowledge of skelp welding and joining techniques, as well as your ability to identify and resolve defects.

- Showcase your commitment to safety and your ability to maintain a clean and organized work environment.

- Highlight your collaborative nature and your experience working with other teams to achieve common goals.

Essential Experience Highlights for a Strong Skelp Processor Resume

- Operate skelp mill equipment, including furnaces, forming rolls, and welding machines, to produce skelp to specified dimensions and quality standards.

- Monitor and control production variables such as temperature, speed, and pressure to ensure optimal skelp quality and dimensional accuracy.

- Inspect skelp for defects and nonconformances using visual and non-destructive testing methods.

- Perform preventive maintenance and repairs on skelp mill equipment to minimize downtime and ensure efficient operation.

- Follow safety protocols and maintain a clean and organized work environment.

- Collaborate with other teams, including engineers, maintenance personnel, and quality control staff, to optimize production processes and improve product quality.

- Assist in the development and implementation of new product specifications and process improvements.

Frequently Asked Questions (FAQ’s) For Skelp Processor

What is the role of a Skelp Processor?

A Skelp Processor is responsible for operating skelp mill equipment, monitoring and controlling production variables, inspecting skelp for defects and nonconformances, and performing preventive maintenance and repairs. They work to ensure that skelp is produced to specified dimensions and quality standards.

What skills are required to be a successful Skelp Processor?

To be a successful Skelp Processor, you should have experience in operating skelp mill equipment, monitoring and controlling production variables, inspecting skelp for defects and nonconformances, and performing preventive maintenance and repairs. You should also be familiar with skelp welding and joining techniques, hot rolling mill setup and operation, and skelp quality control and inspection.

What is the work environment of a Skelp Processor like?

Skelp Processors typically work in a manufacturing environment, operating skelp mill equipment and performing inspections. They may be exposed to noise, heat, and fumes, and may work in areas with limited visibility.

What are the career advancement opportunities for a Skelp Processor?

Skelp Processors may advance to become supervisors or managers in the metalworking industry. They may also move into roles in quality control, production planning, or engineering.

What is the job outlook for Skelp Processors?

The job outlook for Skelp Processors is expected to be good, as the demand for skelp is expected to grow in the coming years.

What are the salary expectations for Skelp Processors?

The salary expectations for Skelp Processors vary depending on experience, location, and company size. However, according to Indeed, the average salary for Skelp Processors in the United States is around $60,000 per year.

What are the educational requirements for Skelp Processors?

Skelp Processors typically need a high school diploma or equivalent. Some employers may prefer candidates with a bachelor’s degree in mechanical engineering or a related field.