Are you a seasoned Skin Pass Operator seeking a new career path? Discover our professionally built Skin Pass Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

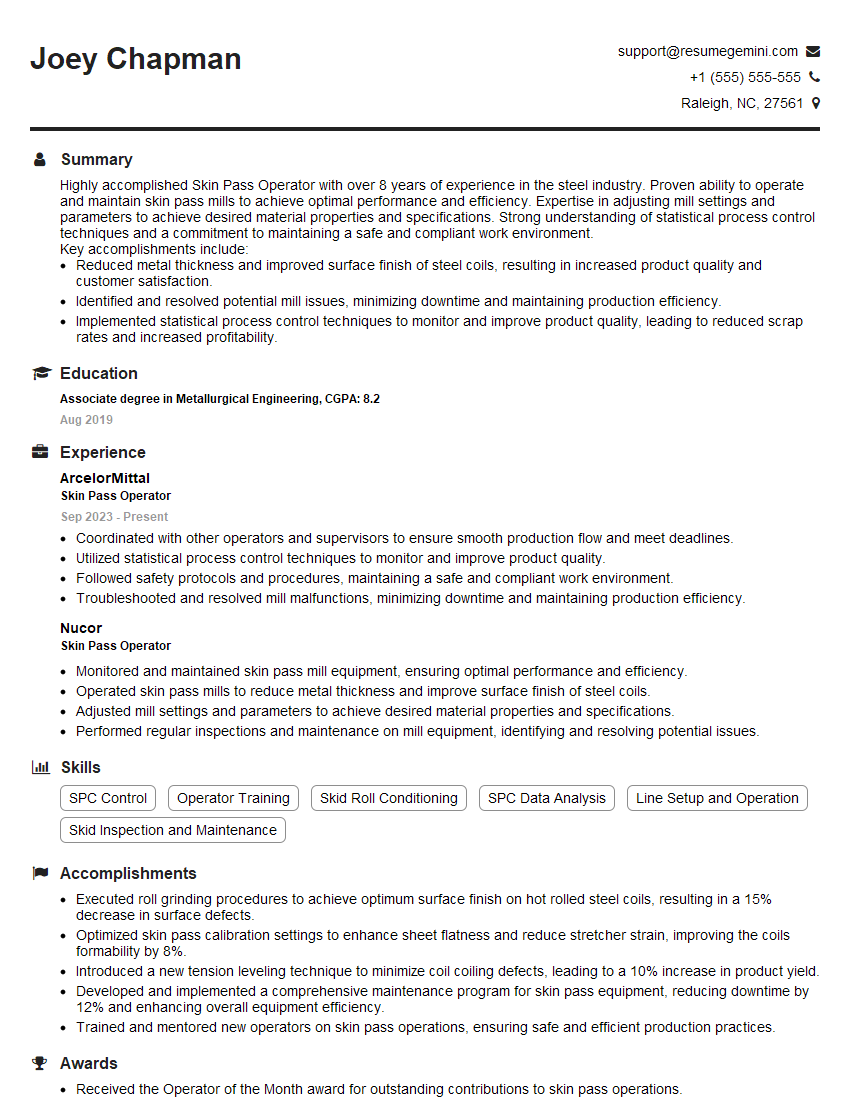

Joey Chapman

Skin Pass Operator

Summary

Highly accomplished Skin Pass Operator with over 8 years of experience in the steel industry. Proven ability to operate and maintain skin pass mills to achieve optimal performance and efficiency. Expertise in adjusting mill settings and parameters to achieve desired material properties and specifications. Strong understanding of statistical process control techniques and a commitment to maintaining a safe and compliant work environment.

Key accomplishments include:

- Reduced metal thickness and improved surface finish of steel coils, resulting in increased product quality and customer satisfaction.

- Identified and resolved potential mill issues, minimizing downtime and maintaining production efficiency.

- Implemented statistical process control techniques to monitor and improve product quality, leading to reduced scrap rates and increased profitability.

Education

Associate degree in Metallurgical Engineering

August 2019

Skills

- SPC Control

- Operator Training

- Skid Roll Conditioning

- SPC Data Analysis

- Line Setup and Operation

- Skid Inspection and Maintenance

Work Experience

Skin Pass Operator

- Coordinated with other operators and supervisors to ensure smooth production flow and meet deadlines.

- Utilized statistical process control techniques to monitor and improve product quality.

- Followed safety protocols and procedures, maintaining a safe and compliant work environment.

- Troubleshooted and resolved mill malfunctions, minimizing downtime and maintaining production efficiency.

Skin Pass Operator

- Monitored and maintained skin pass mill equipment, ensuring optimal performance and efficiency.

- Operated skin pass mills to reduce metal thickness and improve surface finish of steel coils.

- Adjusted mill settings and parameters to achieve desired material properties and specifications.

- Performed regular inspections and maintenance on mill equipment, identifying and resolving potential issues.

Accomplishments

- Executed roll grinding procedures to achieve optimum surface finish on hot rolled steel coils, resulting in a 15% decrease in surface defects.

- Optimized skin pass calibration settings to enhance sheet flatness and reduce stretcher strain, improving the coils formability by 8%.

- Introduced a new tension leveling technique to minimize coil coiling defects, leading to a 10% increase in product yield.

- Developed and implemented a comprehensive maintenance program for skin pass equipment, reducing downtime by 12% and enhancing overall equipment efficiency.

- Trained and mentored new operators on skin pass operations, ensuring safe and efficient production practices.

Awards

- Received the Operator of the Month award for outstanding contributions to skin pass operations.

- Recognized for implementing innovative techniques that significantly improved skin pass efficiency.

- Awarded the Safety Excellence Award for exemplary adherence to safety protocols in the skin pass area.

Certificates

- Certified Skin Pass Operator

- Certified Six Sigma Green Belt

- Certified Lean Practitioner

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Skin Pass Operator

Highlight your technical skills and experience.

Skin pass operators need to have a strong understanding of the equipment they operate and the processes they perform. Be sure to list your skills and experience in your resume, and provide specific examples of how you have used them to improve quality and efficiency.Quantify your accomplishments.

When possible, use numbers to quantify your accomplishments. This will help employers see the impact of your work and how you have contributed to the success of your company.Demonstrate your commitment to safety.

Safety is a top priority in the steel industry. Highlight your commitment to safety in your resume by describing your experience with safety protocols and procedures.Proofread your resume carefully.

Make sure your resume is free of errors and that it is well-written and easy to read. A well-crafted resume will make a good impression on potential employers.

Essential Experience Highlights for a Strong Skin Pass Operator Resume

- Monitored and maintained skin pass mill equipment, ensuring optimal performance and efficiency.

- Operated skin pass mills to reduce metal thickness and improve surface finish of steel coils.

- Adjusted mill settings and parameters to achieve desired material properties and specifications.

- Performed regular inspections and maintenance on mill equipment, identifying and resolving potential issues.

- Coordinated with other operators and supervisors to ensure smooth production flow and meet deadlines.

- Utilized statistical process control techniques to monitor and improve product quality.

- Followed safety protocols and procedures, maintaining a safe and compliant work environment.

- Troubleshooted and resolved mill malfunctions, minimizing downtime and maintaining production efficiency.

Frequently Asked Questions (FAQ’s) For Skin Pass Operator

What is a skin pass mill?

A skin pass mill is a type of cold rolling mill that is used to reduce the thickness and improve the surface finish of steel coils.

What is the purpose of a skin pass?

The purpose of a skin pass is to improve the surface finish of steel coils and to make them more resistant to scratches and corrosion.

What are the different types of skin pass mills?

There are two main types of skin pass mills: single-stand and two-stand mills.

What are the benefits of using a skin pass mill?

The benefits of using a skin pass mill include improved surface finish, reduced thickness, and increased resistance to scratches and corrosion.

What are the challenges of operating a skin pass mill?

The challenges of operating a skin pass mill include maintaining tight tolerances, controlling the thickness of the steel coils, and ensuring that the surface finish is free of defects.

What are the safety precautions that must be taken when operating a skin pass mill?

The safety precautions that must be taken when operating a skin pass mill include wearing proper safety gear, following all safety procedures, and being aware of the potential hazards of the equipment.

What are the career opportunities for skin pass operators?

The career opportunities for skin pass operators include promotion to supervisor, quality control inspector, or maintenance technician.