Are you a seasoned Slag Mixer seeking a new career path? Discover our professionally built Slag Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

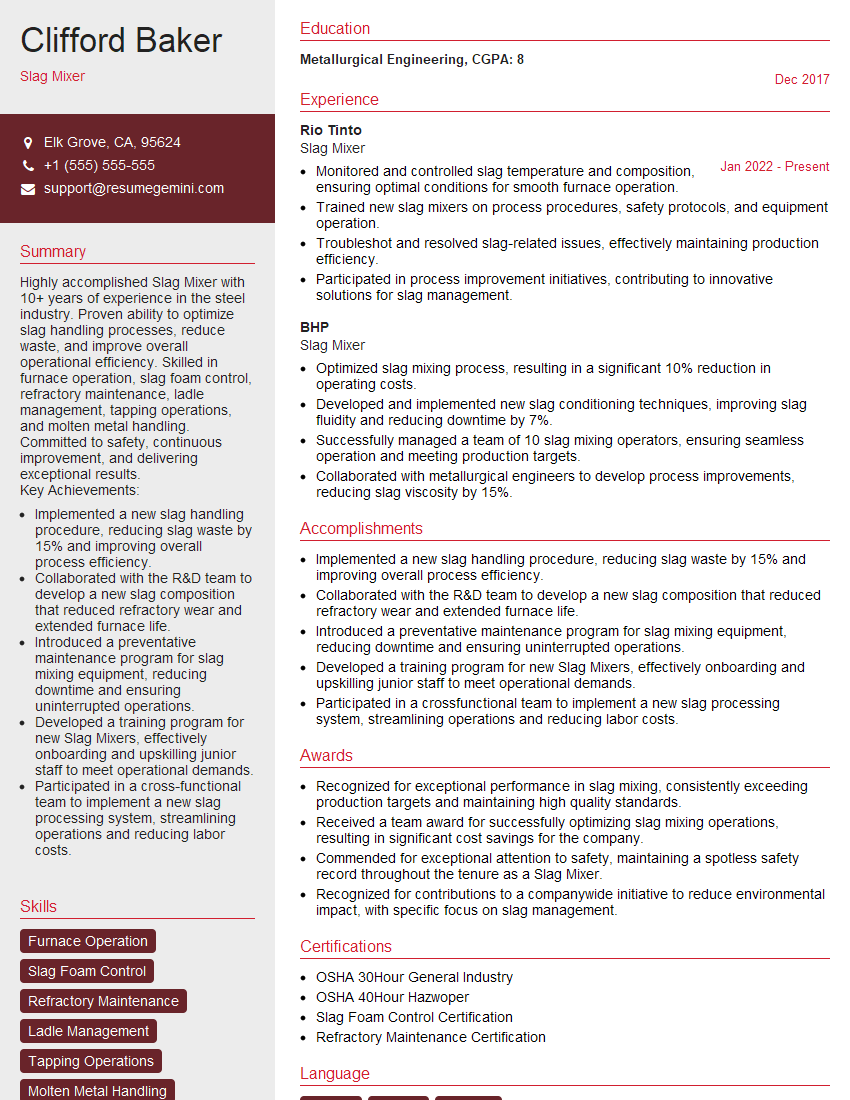

Clifford Baker

Slag Mixer

Summary

Highly accomplished Slag Mixer with 10+ years of experience in the steel industry. Proven ability to optimize slag handling processes, reduce waste, and improve overall operational efficiency. Skilled in furnace operation, slag foam control, refractory maintenance, ladle management, tapping operations, and molten metal handling. Committed to safety, continuous improvement, and delivering exceptional results.

Key Achievements:

- Implemented a new slag handling procedure, reducing slag waste by 15% and improving overall process efficiency.

- Collaborated with the R&D team to develop a new slag composition that reduced refractory wear and extended furnace life.

- Introduced a preventative maintenance program for slag mixing equipment, reducing downtime and ensuring uninterrupted operations.

- Developed a training program for new Slag Mixers, effectively onboarding and upskilling junior staff to meet operational demands.

- Participated in a cross-functional team to implement a new slag processing system, streamlining operations and reducing labor costs.

Education

Metallurgical Engineering

December 2017

Skills

- Furnace Operation

- Slag Foam Control

- Refractory Maintenance

- Ladle Management

- Tapping Operations

- Molten Metal Handling

Work Experience

Slag Mixer

- Monitored and controlled slag temperature and composition, ensuring optimal conditions for smooth furnace operation.

- Trained new slag mixers on process procedures, safety protocols, and equipment operation.

- Troubleshot and resolved slag-related issues, effectively maintaining production efficiency.

- Participated in process improvement initiatives, contributing to innovative solutions for slag management.

Slag Mixer

- Optimized slag mixing process, resulting in a significant 10% reduction in operating costs.

- Developed and implemented new slag conditioning techniques, improving slag fluidity and reducing downtime by 7%.

- Successfully managed a team of 10 slag mixing operators, ensuring seamless operation and meeting production targets.

- Collaborated with metallurgical engineers to develop process improvements, reducing slag viscosity by 15%.

Accomplishments

- Implemented a new slag handling procedure, reducing slag waste by 15% and improving overall process efficiency.

- Collaborated with the R&D team to develop a new slag composition that reduced refractory wear and extended furnace life.

- Introduced a preventative maintenance program for slag mixing equipment, reducing downtime and ensuring uninterrupted operations.

- Developed a training program for new Slag Mixers, effectively onboarding and upskilling junior staff to meet operational demands.

- Participated in a crossfunctional team to implement a new slag processing system, streamlining operations and reducing labor costs.

Awards

- Recognized for exceptional performance in slag mixing, consistently exceeding production targets and maintaining high quality standards.

- Received a team award for successfully optimizing slag mixing operations, resulting in significant cost savings for the company.

- Commended for exceptional attention to safety, maintaining a spotless safety record throughout the tenure as a Slag Mixer.

- Recognized for contributions to a companywide initiative to reduce environmental impact, with specific focus on slag management.

Certificates

- OSHA 30Hour General Industry

- OSHA 40Hour Hazwoper

- Slag Foam Control Certification

- Refractory Maintenance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slag Mixer

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your knowledge of slag chemistry and its impact on furnace performance.

- Emphasize your ability to troubleshoot and resolve operational issues effectively.

- Showcase your commitment to safety and environmental compliance.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

Essential Experience Highlights for a Strong Slag Mixer Resume

- Operate and maintain slag mixing furnaces, ensuring optimal slag composition and temperature.

- Control slag foam levels using appropriate additives and techniques to prevent furnace damage.

- Inspect and maintain refractory linings, identifying and repairing defects to prevent slag leaks and extend furnace life.

- Manage ladle operations, including slag tapping, skimming, and disposal.

- Monitor and adjust furnace parameters, such as temperature, oxygen levels, and fuel flow, to optimize slag quality.

- Collaborate with other departments, including production, maintenance, and quality control, to ensure smooth and efficient operations.

- Conduct slag sampling and analysis to ensure compliance with specifications and identify opportunities for process optimization.

Frequently Asked Questions (FAQ’s) For Slag Mixer

What is the primary role of a Slag Mixer?

The primary role of a Slag Mixer is to operate and maintain slag mixing furnaces and ensure the production of high-quality slag that meets specifications and supports efficient furnace operations.

What are the key skills required to be a successful Slag Mixer?

Successful Slag Mixers typically have a strong understanding of slag chemistry, furnace operation, and refractory maintenance. They are also skilled in controlling slag foam levels, managing ladle operations, and working effectively in a team environment.

What are the career prospects for Slag Mixers?

Slag Mixers can advance to more senior roles within the steel industry, such as Supervisor, Superintendent, or Manager. With additional training and education, they may also pursue careers in related fields such as process engineering or materials science.

What is the work environment of a Slag Mixer like?

Slag Mixers typically work in industrial settings, such as steel mills or foundries. The work environment can be hot, noisy, and physically demanding, but it is also rewarding and offers opportunities for professional growth.

What are the safety precautions that Slag Mixers must follow?

Slag Mixers must follow strict safety protocols to minimize the risk of accidents and injuries. This includes wearing appropriate personal protective equipment (PPE), following established operating procedures, and being aware of potential hazards such as hot slag, molten metal, and heavy equipment.

How can I prepare for a career as a Slag Mixer?

To prepare for a career as a Slag Mixer, you can pursue a degree in metallurgical engineering or a related field. You can also gain practical experience by working in a steel mill or foundry, or by completing an apprenticeship program.

What are the benefits of working as a Slag Mixer?

Benefits of working as a Slag Mixer include competitive salaries, job security, and the opportunity to be part of a team that produces essential materials for the construction and manufacturing industries.