Are you a seasoned Slag Motor Operator seeking a new career path? Discover our professionally built Slag Motor Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

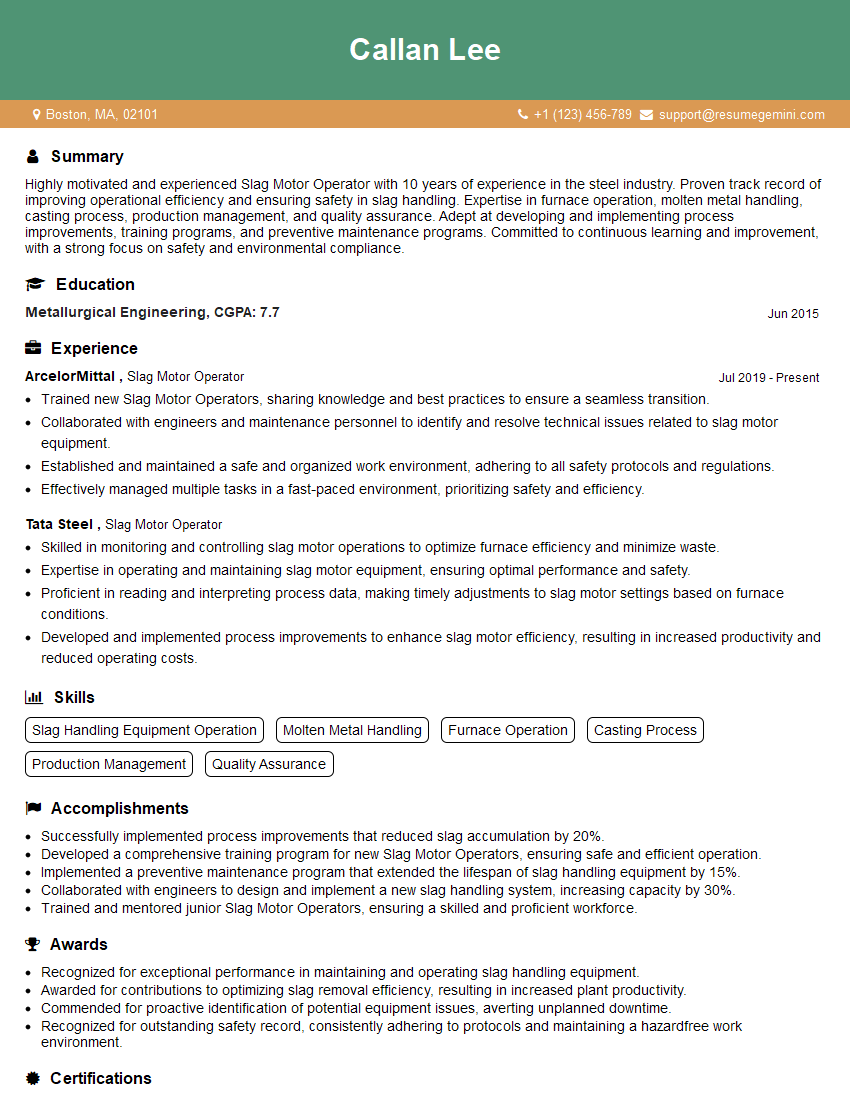

Callan Lee

Slag Motor Operator

Summary

Highly motivated and experienced Slag Motor Operator with 10 years of experience in the steel industry. Proven track record of improving operational efficiency and ensuring safety in slag handling. Expertise in furnace operation, molten metal handling, casting process, production management, and quality assurance. Adept at developing and implementing process improvements, training programs, and preventive maintenance programs. Committed to continuous learning and improvement, with a strong focus on safety and environmental compliance.

Education

Metallurgical Engineering

June 2015

Skills

- Slag Handling Equipment Operation

- Molten Metal Handling

- Furnace Operation

- Casting Process

- Production Management

- Quality Assurance

Work Experience

Slag Motor Operator

- Trained new Slag Motor Operators, sharing knowledge and best practices to ensure a seamless transition.

- Collaborated with engineers and maintenance personnel to identify and resolve technical issues related to slag motor equipment.

- Established and maintained a safe and organized work environment, adhering to all safety protocols and regulations.

- Effectively managed multiple tasks in a fast-paced environment, prioritizing safety and efficiency.

Slag Motor Operator

- Skilled in monitoring and controlling slag motor operations to optimize furnace efficiency and minimize waste.

- Expertise in operating and maintaining slag motor equipment, ensuring optimal performance and safety.

- Proficient in reading and interpreting process data, making timely adjustments to slag motor settings based on furnace conditions.

- Developed and implemented process improvements to enhance slag motor efficiency, resulting in increased productivity and reduced operating costs.

Accomplishments

- Successfully implemented process improvements that reduced slag accumulation by 20%.

- Developed a comprehensive training program for new Slag Motor Operators, ensuring safe and efficient operation.

- Implemented a preventive maintenance program that extended the lifespan of slag handling equipment by 15%.

- Collaborated with engineers to design and implement a new slag handling system, increasing capacity by 30%.

- Trained and mentored junior Slag Motor Operators, ensuring a skilled and proficient workforce.

Awards

- Recognized for exceptional performance in maintaining and operating slag handling equipment.

- Awarded for contributions to optimizing slag removal efficiency, resulting in increased plant productivity.

- Commended for proactive identification of potential equipment issues, averting unplanned downtime.

- Recognized for outstanding safety record, consistently adhering to protocols and maintaining a hazardfree work environment.

Certificates

- Certified Slag Motor Operator

- OSHA Safety Certification

- Molten Metal Handling Certification

- Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slag Motor Operator

- Highlight your experience in slag handling equipment operation, molten metal handling, and furnace operation.

- Emphasize your ability to improve operational efficiency through process improvements and preventive maintenance.

- Showcase your skills in training and mentoring junior operators, ensuring a skilled workforce.

- Quantify your achievements with specific metrics, such as reduced slag accumulation, extended equipment lifespan, and increased production capacity.

- Obtain relevant certifications, such as the Slag Motor Operator Certification from the Steel Manufacturers Association.

Essential Experience Highlights for a Strong Slag Motor Operator Resume

- Operate slag motor to remove slag from furnaces, ensuring efficient and safe slag handling.

- Control furnace temperature and molten metal flow, maintaining optimal conditions for casting.

- Monitor slag composition and adjust operating parameters to meet quality standards.

- Perform preventive maintenance on slag handling equipment to extend equipment lifespan and minimize downtime.

- Collaborate with engineers to improve slag handling processes and systems, increasing production capacity.

- Supervise and mentor junior Slag Motor Operators, ensuring proficiency and adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Slag Motor Operator

What are the primary responsibilities of a Slag Motor Operator?

Slag Motor Operators are responsible for operating slag handling equipment to move slag away from furnaces, controlling furnace temperature and melt flow, monitoring slag composition, and performing preventive maintenance on equipment.

What skills are required to be a successful Slag Motor Operator?

Successful Slag Motor Operators possess expertise in slag handling equipment operation, molten metal handling, furnace operation, casting processes, production management, and quality assurance.

What are the career prospects for Slag Motor Operators?

Slag Motor Operators can advance to supervisory roles, such as Slag Handling Supervisor or Production Supervisor, or specialize in areas such as equipment maintenance or process engineering.

What is the work environment of a Slag Motor Operator like?

Slag Motor Operators typically work in industrial settings, such as steel mills or foundries, and may be exposed to heat, noise, and molten metal.

What are the safety precautions that Slag Motor Operators must follow?

Slag Motor Operators must wear appropriate protective gear, including fire-resistant clothing, hard hats, and safety glasses, and adhere to strict safety protocols to minimize risks associated with molten metal handling and slag removal.

What is the average salary of a Slag Motor Operator?

The average salary of a Slag Motor Operator varies depending on experience, location, and industry, but typically ranges from $50,000 to $75,000 per year.

What are the educational requirements to become a Slag Motor Operator?

While formal education requirements may vary, many Slag Motor Operators have a high school diploma or equivalent, along with on-the-job training or apprenticeship programs.