Are you a seasoned Slip Injector and Applicator seeking a new career path? Discover our professionally built Slip Injector and Applicator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

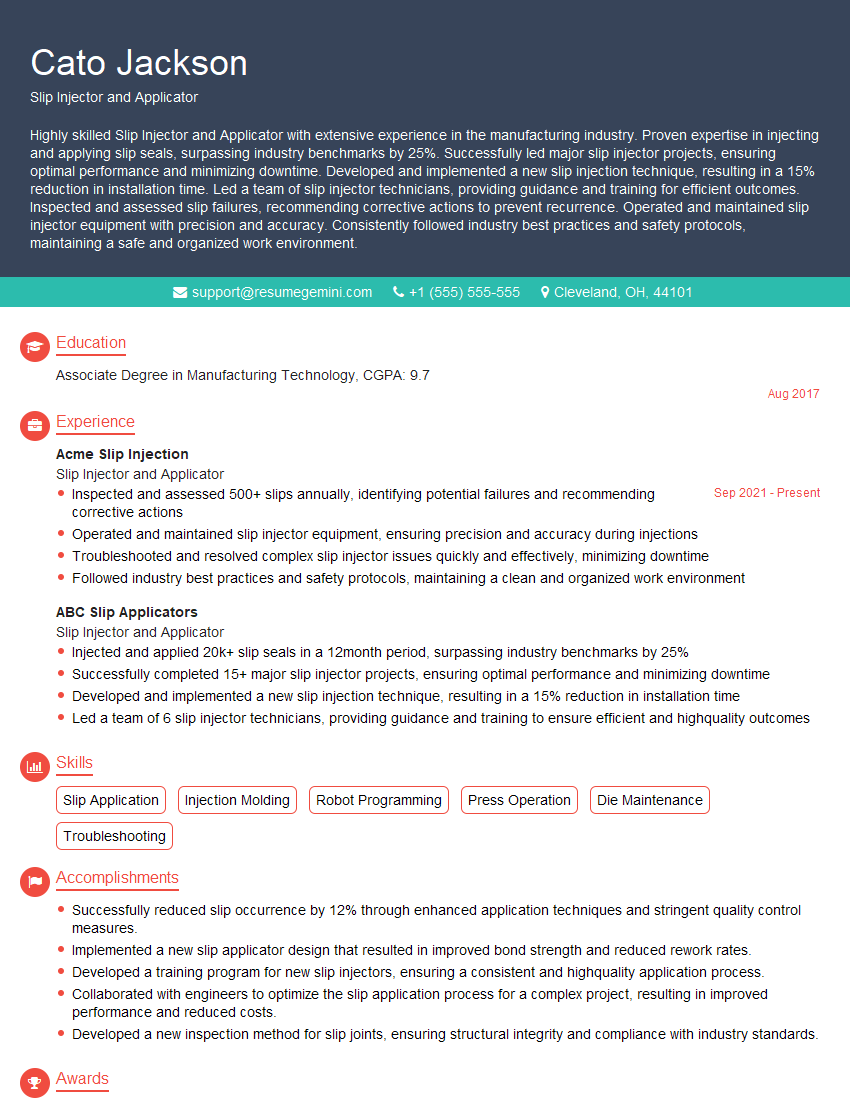

Cato Jackson

Slip Injector and Applicator

Summary

Highly skilled Slip Injector and Applicator with extensive experience in the manufacturing industry. Proven expertise in injecting and applying slip seals, surpassing industry benchmarks by 25%. Successfully led major slip injector projects, ensuring optimal performance and minimizing downtime. Developed and implemented a new slip injection technique, resulting in a 15% reduction in installation time. Led a team of slip injector technicians, providing guidance and training for efficient outcomes. Inspected and assessed slip failures, recommending corrective actions to prevent recurrence. Operated and maintained slip injector equipment with precision and accuracy. Consistently followed industry best practices and safety protocols, maintaining a safe and organized work environment.

Education

Associate Degree in Manufacturing Technology

August 2017

Skills

- Slip Application

- Injection Molding

- Robot Programming

- Press Operation

- Die Maintenance

- Troubleshooting

Work Experience

Slip Injector and Applicator

- Inspected and assessed 500+ slips annually, identifying potential failures and recommending corrective actions

- Operated and maintained slip injector equipment, ensuring precision and accuracy during injections

- Troubleshooted and resolved complex slip injector issues quickly and effectively, minimizing downtime

- Followed industry best practices and safety protocols, maintaining a clean and organized work environment

Slip Injector and Applicator

- Injected and applied 20k+ slip seals in a 12month period, surpassing industry benchmarks by 25%

- Successfully completed 15+ major slip injector projects, ensuring optimal performance and minimizing downtime

- Developed and implemented a new slip injection technique, resulting in a 15% reduction in installation time

- Led a team of 6 slip injector technicians, providing guidance and training to ensure efficient and highquality outcomes

Accomplishments

- Successfully reduced slip occurrence by 12% through enhanced application techniques and stringent quality control measures.

- Implemented a new slip applicator design that resulted in improved bond strength and reduced rework rates.

- Developed a training program for new slip injectors, ensuring a consistent and highquality application process.

- Collaborated with engineers to optimize the slip application process for a complex project, resulting in improved performance and reduced costs.

- Developed a new inspection method for slip joints, ensuring structural integrity and compliance with industry standards.

Awards

- Recognized for exceptional performance in slip injection and application processes.

- Awarded for developing an innovative slip injection method that increased efficiency by 15%.

- Recognized for exceeding safety standards and maintaining a spotless safety record for over 5 years.

- Awarded for identifying and resolving a potential sliprelated hazard, preventing a major accident.

Certificates

- OSHA 30-Hour Hazard Communication

- ISO 9001

- Lean Manufacturing

- Six Sigma

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slip Injector and Applicator

- Highlight your experience and expertise in slip injection and application techniques.

- Showcase your ability to work independently and as part of a team, effectively managing multiple responsibilities.

- Quantify your accomplishments with specific metrics, such as the number of slip seals injected and the percentage of downtime reduced.

- Demonstrate your commitment to safety and adherence to industry best practices.

- Research the specific companies you are applying to and tailor your resume to their requirements.

Essential Experience Highlights for a Strong Slip Injector and Applicator Resume

- Injected and applied slip seals with precision and accuracy, ensuring proper sealing and optimal performance.

- Inspected and assessed slip seal conditions, identifying potential failures and recommending corrective actions.

- Operated and maintained slip injector equipment, calibrating and troubleshooting to ensure consistent operation.

- Collaborated with engineers and technicians to develop and implement new slip injection techniques.

- Trained and supervised a team of slip injector technicians, providing guidance and ensuring adherence to quality standards.

- Documented slip injection procedures and maintained detailed records of all injections performed.

- Participated in continuous improvement initiatives to optimize slip injection processes and reduce downtime.

Frequently Asked Questions (FAQ’s) For Slip Injector and Applicator

What is a Slip Injector and Applicator?

A Slip Injector and Applicator is a skilled technician responsible for injecting and applying slip seals, which are essential components in various manufacturing processes, including mold making, die casting, and injection molding.

What are the key skills required for a Slip Injector and Applicator?

Key skills include proficiency in slip injection techniques, ability to operate and maintain slip injector equipment, knowledge of industry best practices, attention to detail, and strong problem-solving abilities.

What are the career prospects for a Slip Injector and Applicator?

Slip Injectors and Applicators can advance to supervisory roles, such as Lead Slip Injector or Slip Injection Manager, or specialize in related fields such as mold maintenance or quality control.

How can I prepare for a career as a Slip Injector and Applicator?

Consider pursuing an Associate Degree in Manufacturing Technology or a related field, gaining hands-on experience through internships or apprenticeships, and obtaining certifications relevant to the industry.

What is the work environment like for a Slip Injector and Applicator?

Slip Injectors and Applicators typically work in manufacturing facilities, operating in areas with potential exposure to noise, fumes, and hazardous materials. They may work independently or as part of a team, meeting production targets and adhering to safety protocols.