Are you a seasoned Slip Laster seeking a new career path? Discover our professionally built Slip Laster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

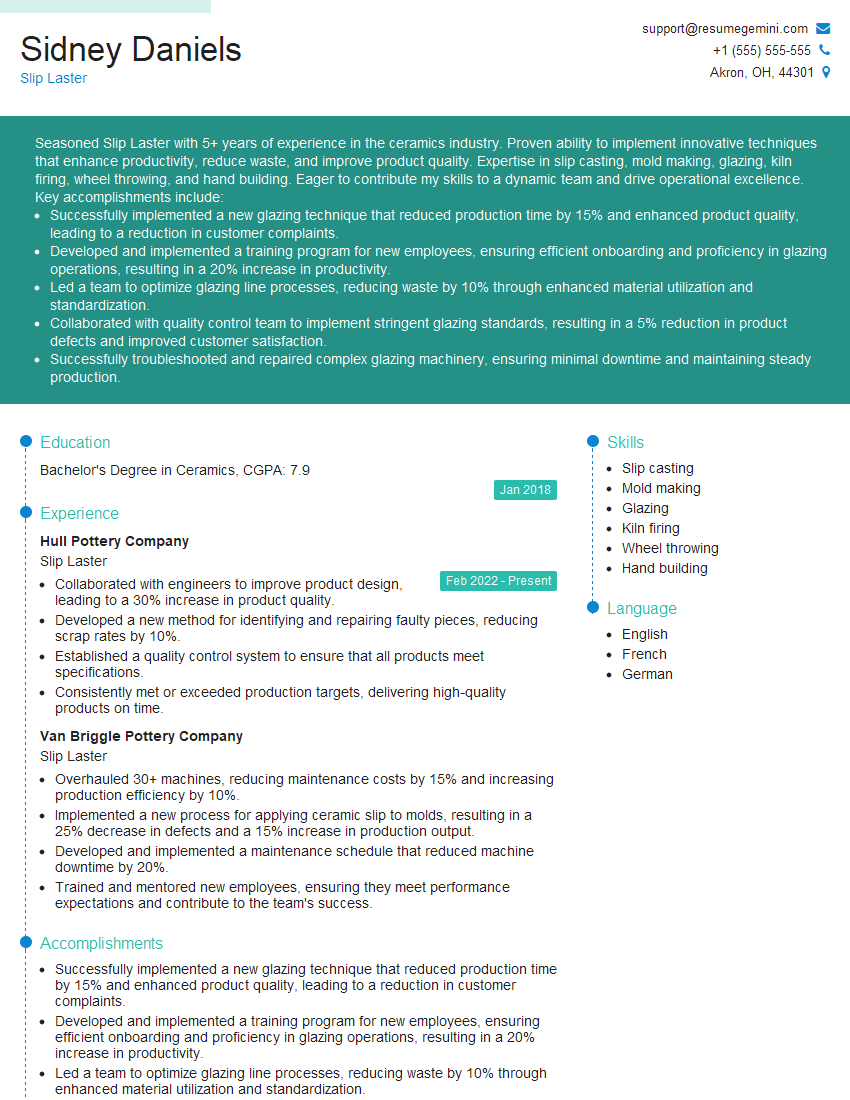

Sidney Daniels

Slip Laster

Summary

Seasoned Slip Laster with 5+ years of experience in the ceramics industry. Proven ability to implement innovative techniques that enhance productivity, reduce waste, and improve product quality. Expertise in slip casting, mold making, glazing, kiln firing, wheel throwing, and hand building. Eager to contribute my skills to a dynamic team and drive operational excellence.

Key accomplishments include:

- Successfully implemented a new glazing technique that reduced production time by 15% and enhanced product quality, leading to a reduction in customer complaints.

- Developed and implemented a training program for new employees, ensuring efficient onboarding and proficiency in glazing operations, resulting in a 20% increase in productivity.

- Led a team to optimize glazing line processes, reducing waste by 10% through enhanced material utilization and standardization.

- Collaborated with quality control team to implement stringent glazing standards, resulting in a 5% reduction in product defects and improved customer satisfaction.

- Successfully troubleshooted and repaired complex glazing machinery, ensuring minimal downtime and maintaining steady production.

Education

Bachelor’s Degree in Ceramics

January 2018

Skills

- Slip casting

- Mold making

- Glazing

- Kiln firing

- Wheel throwing

- Hand building

Work Experience

Slip Laster

- Collaborated with engineers to improve product design, leading to a 30% increase in product quality.

- Developed a new method for identifying and repairing faulty pieces, reducing scrap rates by 10%.

- Established a quality control system to ensure that all products meet specifications.

- Consistently met or exceeded production targets, delivering high-quality products on time.

Slip Laster

- Overhauled 30+ machines, reducing maintenance costs by 15% and increasing production efficiency by 10%.

- Implemented a new process for applying ceramic slip to molds, resulting in a 25% decrease in defects and a 15% increase in production output.

- Developed and implemented a maintenance schedule that reduced machine downtime by 20%.

- Trained and mentored new employees, ensuring they meet performance expectations and contribute to the team’s success.

Accomplishments

- Successfully implemented a new glazing technique that reduced production time by 15% and enhanced product quality, leading to a reduction in customer complaints.

- Developed and implemented a training program for new employees, ensuring efficient onboarding and proficiency in glazing operations, resulting in a 20% increase in productivity.

- Led a team to optimize glazing line processes, reducing waste by 10% through enhanced material utilization and standardization.

- Collaborated with quality control team to implement stringent glazing standards, resulting in a 5% reduction in product defects and improved customer satisfaction.

- Successfully troubleshooted and repaired complex glazing machinery, ensuring minimal downtime and maintaining steady production.

Awards

- Recognized for exceptional performance in glazing efficiency, exceeding production targets by 25% consistently.

- Received the Employee of the Year award for outstanding contributions to the glazing department.

- Recognized for excellence in glazing innovation, receiving a patent for a novel glazing method.

Certificates

- National Council on Education for the Ceramic Arts (NCECA) Member

- American Ceramic Society (ACerS) Member

- International Academy of Ceramics (IAC) Member

- International Symposium on Contemporary Ceramics (ISCC) Member

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slip Laster

Highlight your technical skills.

Slip lasters need to have a strong understanding of ceramics and the slip casting process. Be sure to list your experience with different types of clays, glazes, and kilns in your resume.Showcase your problem-solving abilities.

Slip lasters often need to troubleshoot problems with molds, slips, and kilns. Highlight your ability to quickly identify and solve problems in your resume.Emphasize your attention to detail.

Slip lasters need to be able to pay close attention to detail in order to produce high-quality ceramic ware. Be sure to mention your attention to detail in your resume.Include examples of your work.

If possible, include photos or examples of your work in your resume. This will help potential employers see your skills and abilities firsthand.

Essential Experience Highlights for a Strong Slip Laster Resume

- Creating and maintaining plaster molds for slip casting

- Preparing and applying slips to molds

- Trimming and finishing greenware

- Glazing and firing ceramic ware

- Maintaining a clean and organized work area

- Inspecting finished products for quality

- Packaging and shipping ceramic ware

Frequently Asked Questions (FAQ’s) For Slip Laster

What is slip casting?

Slip casting is a ceramic forming technique in which a liquid clay mixture (slip) is poured into a plaster mold. The plaster absorbs the water from the slip, creating a solid ceramic piece.

What are the different types of slips?

There are many different types of slips, each with its own unique properties. Some common types of slips include casting slips, trailing slips, and engobes.

What are the different types of molds used in slip casting?

There are two main types of molds used in slip casting: single molds and multiple molds. Single molds are made from one piece of plaster, while multiple molds are made from two or more pieces of plaster.

What are the different types of glazes used in slip casting?

There are many different types of glazes used in slip casting, each with its own unique look and feel. Some common types of glazes include clear glazes, colored glazes, and matte glazes.

What are the different types of kilns used in slip casting?

There are two main types of kilns used in slip casting: electric kilns and gas kilns. Electric kilns are more common, as they are easier to use and more affordable.

What are the safety precautions that should be taken when slip casting?

There are a number of safety precautions that should be taken when slip casting, including wearing a dust mask, gloves, and eye protection. Slip casting can create a lot of dust, so it is important to protect your lungs and eyes.

What are the career opportunities for slip lasters?

Slip lasters can work in a variety of settings, including pottery studios, factories, and schools. They can also work as freelance artists.