Are you a seasoned Slitter Cut Off Operator seeking a new career path? Discover our professionally built Slitter Cut Off Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

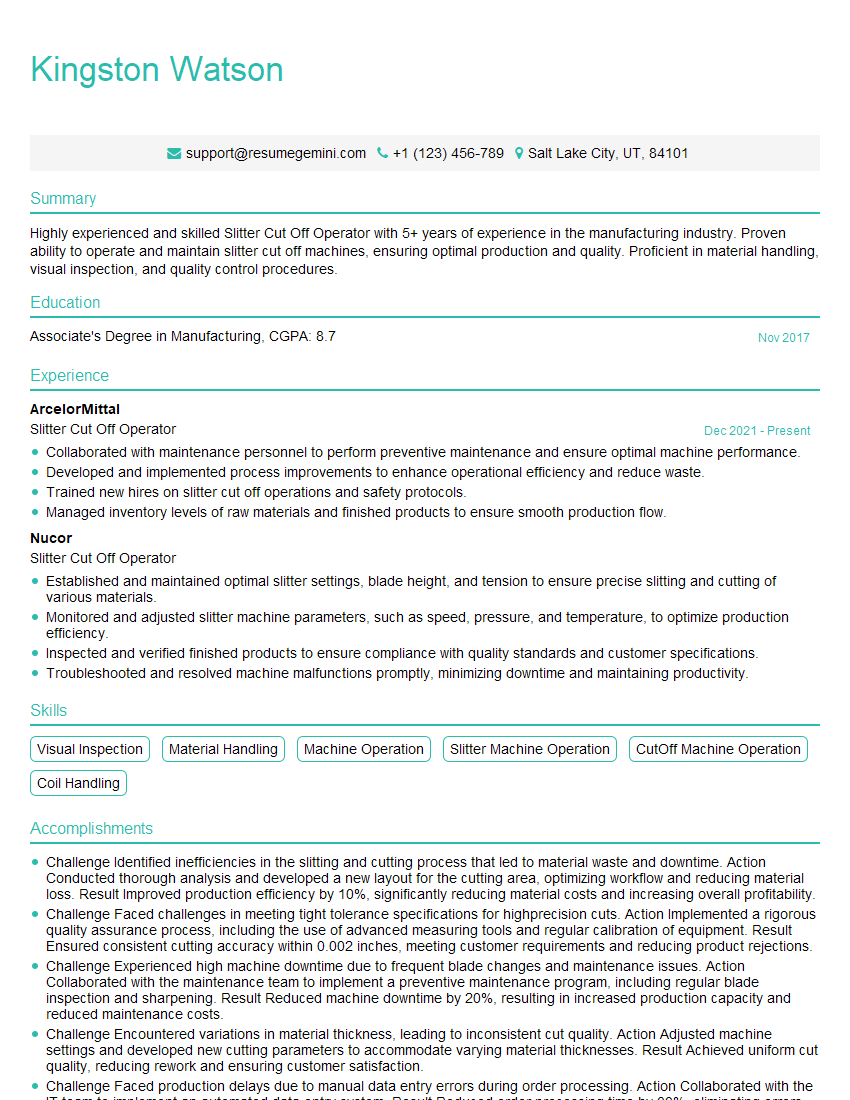

Kingston Watson

Slitter Cut Off Operator

Summary

Highly experienced and skilled Slitter Cut Off Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain slitter cut off machines, ensuring optimal production and quality. Proficient in material handling, visual inspection, and quality control procedures.

Education

Associate’s Degree in Manufacturing

November 2017

Skills

- Visual Inspection

- Material Handling

- Machine Operation

- Slitter Machine Operation

- CutOff Machine Operation

- Coil Handling

Work Experience

Slitter Cut Off Operator

- Collaborated with maintenance personnel to perform preventive maintenance and ensure optimal machine performance.

- Developed and implemented process improvements to enhance operational efficiency and reduce waste.

- Trained new hires on slitter cut off operations and safety protocols.

- Managed inventory levels of raw materials and finished products to ensure smooth production flow.

Slitter Cut Off Operator

- Established and maintained optimal slitter settings, blade height, and tension to ensure precise slitting and cutting of various materials.

- Monitored and adjusted slitter machine parameters, such as speed, pressure, and temperature, to optimize production efficiency.

- Inspected and verified finished products to ensure compliance with quality standards and customer specifications.

- Troubleshooted and resolved machine malfunctions promptly, minimizing downtime and maintaining productivity.

Accomplishments

- Challenge Identified inefficiencies in the slitting and cutting process that led to material waste and downtime. Action Conducted thorough analysis and developed a new layout for the cutting area, optimizing workflow and reducing material loss. Result Improved production efficiency by 10%, significantly reducing material costs and increasing overall profitability.

- Challenge Faced challenges in meeting tight tolerance specifications for highprecision cuts. Action Implemented a rigorous quality assurance process, including the use of advanced measuring tools and regular calibration of equipment. Result Ensured consistent cutting accuracy within 0.002 inches, meeting customer requirements and reducing product rejections.

- Challenge Experienced high machine downtime due to frequent blade changes and maintenance issues. Action Collaborated with the maintenance team to implement a preventive maintenance program, including regular blade inspection and sharpening. Result Reduced machine downtime by 20%, resulting in increased production capacity and reduced maintenance costs.

- Challenge Encountered variations in material thickness, leading to inconsistent cut quality. Action Adjusted machine settings and developed new cutting parameters to accommodate varying material thicknesses. Result Achieved uniform cut quality, reducing rework and ensuring customer satisfaction.

- Challenge Faced production delays due to manual data entry errors during order processing. Action Collaborated with the IT team to implement an automated data entry system. Result Reduced order processing time by 30%, eliminating errors and improving overall efficiency.

Awards

- Received Employee of the Month award for maintaining an exceptional safety record and consistently meeting production goals.

- Recognized with the Team Excellence Award for collaborating with colleagues to implement new process improvements that increased efficiency by 15%.

- Awarded Safety Champion recognition for implementing innovative safety protocols and maintaining a spotless safety record.

- Honored with the Excellence in Operations award for exceptional performance in maintaining a clean and organized work environment.

Certificates

- OSHA Safety Certification

- Lean Six Sigma Certification

- ISO 9001 Certification

- PMP (Project Management Professional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slitter Cut Off Operator

- Highlight your experience in operating slitter cut off machines and related equipment.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your knowledge of quality control procedures and adherence to industry standards.

- Emphasize your ability to work independently and as part of a team in a fast-paced production environment.

Essential Experience Highlights for a Strong Slitter Cut Off Operator Resume

- Operate and maintain slitter cut off machines to slit and cut metal coils to specified dimensions.

- Handle and load heavy materials, including metal coils, sheets, and strips.

- Perform visual inspections of materials and finished products to ensure quality and adherence to specifications.

- Monitor machine performance and make necessary adjustments to optimize production and minimize downtime.

- Maintain a clean and organized work area to ensure safety and efficiency.

- Troubleshoot and resolve machine malfunctions to minimize production interruptions.

Frequently Asked Questions (FAQ’s) For Slitter Cut Off Operator

What are the primary duties of a Slitter Cut Off Operator?

Slitter Cut Off Operators are responsible for operating and maintaining slitter cut off machines to slit and cut metal coils to specified dimensions, handling heavy materials, performing visual inspections, monitoring machine performance, and maintaining a clean and organized work area.

What skills are required to be a successful Slitter Cut Off Operator?

Successful Slitter Cut Off Operators possess strong machine operation skills, proficiency in material handling, attention to detail, and a commitment to safety and quality.

What is the work environment like for a Slitter Cut Off Operator?

Slitter Cut Off Operators typically work in manufacturing facilities, operating machinery in a fast-paced and often noisy environment.

What are the career prospects for a Slitter Cut Off Operator?

With experience and additional training, Slitter Cut Off Operators can advance to positions such as Machine Supervisor, Production Manager, or Quality Control Inspector.

What is the average salary for a Slitter Cut Off Operator?

The average salary for a Slitter Cut Off Operator can vary depending on experience, location, and industry, but typically ranges from $30,000 to $50,000 per year.