Are you a seasoned Slotter Operator seeking a new career path? Discover our professionally built Slotter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

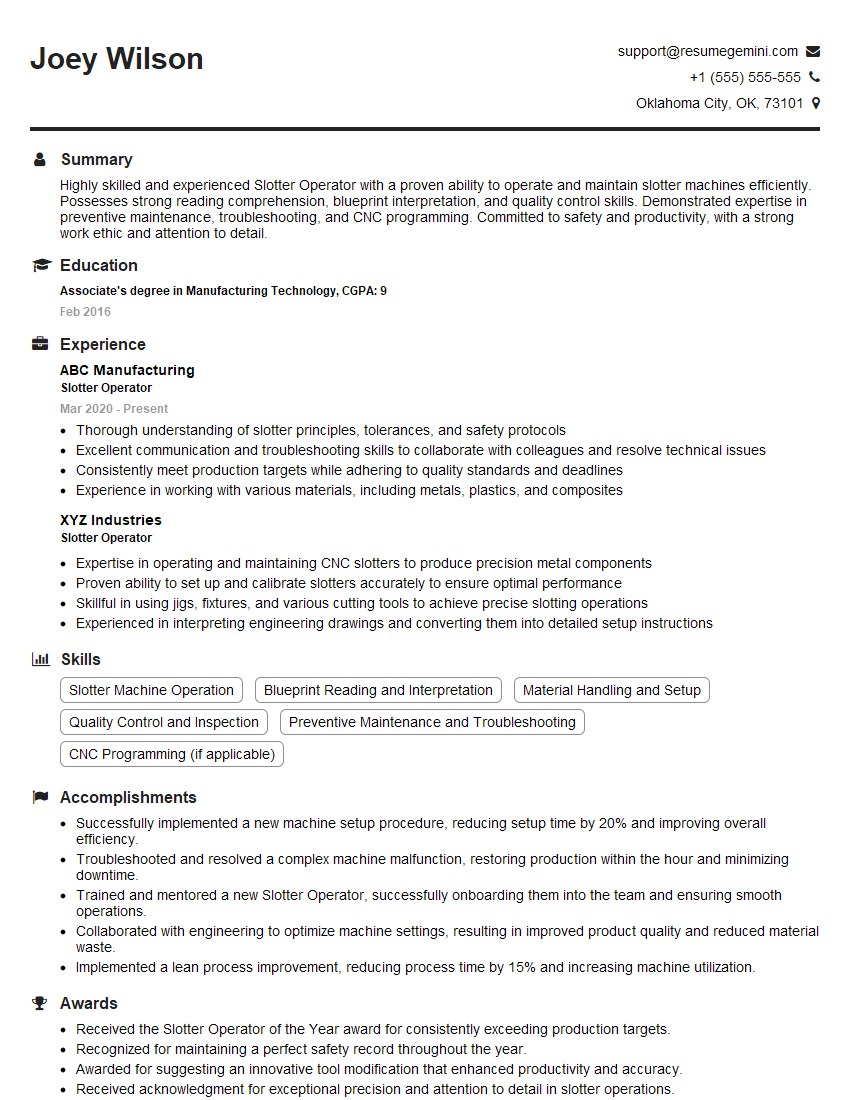

Joey Wilson

Slotter Operator

Summary

Highly skilled and experienced Slotter Operator with a proven ability to operate and maintain slotter machines efficiently. Possesses strong reading comprehension, blueprint interpretation, and quality control skills. Demonstrated expertise in preventive maintenance, troubleshooting, and CNC programming. Committed to safety and productivity, with a strong work ethic and attention to detail.

Education

Associate’s degree in Manufacturing Technology

February 2016

Skills

- Slotter Machine Operation

- Blueprint Reading and Interpretation

- Material Handling and Setup

- Quality Control and Inspection

- Preventive Maintenance and Troubleshooting

- CNC Programming (if applicable)

Work Experience

Slotter Operator

- Thorough understanding of slotter principles, tolerances, and safety protocols

- Excellent communication and troubleshooting skills to collaborate with colleagues and resolve technical issues

- Consistently meet production targets while adhering to quality standards and deadlines

- Experience in working with various materials, including metals, plastics, and composites

Slotter Operator

- Expertise in operating and maintaining CNC slotters to produce precision metal components

- Proven ability to set up and calibrate slotters accurately to ensure optimal performance

- Skillful in using jigs, fixtures, and various cutting tools to achieve precise slotting operations

- Experienced in interpreting engineering drawings and converting them into detailed setup instructions

Accomplishments

- Successfully implemented a new machine setup procedure, reducing setup time by 20% and improving overall efficiency.

- Troubleshooted and resolved a complex machine malfunction, restoring production within the hour and minimizing downtime.

- Trained and mentored a new Slotter Operator, successfully onboarding them into the team and ensuring smooth operations.

- Collaborated with engineering to optimize machine settings, resulting in improved product quality and reduced material waste.

- Implemented a lean process improvement, reducing process time by 15% and increasing machine utilization.

Awards

- Received the Slotter Operator of the Year award for consistently exceeding production targets.

- Recognized for maintaining a perfect safety record throughout the year.

- Awarded for suggesting an innovative tool modification that enhanced productivity and accuracy.

- Received acknowledgment for exceptional precision and attention to detail in slotter operations.

Certificates

- Certified Slotter Operator (CSO)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Slotter Operator

- Highlight your proficiency in blueprint reading, measurement tools, and quality control techniques.

- Showcase your problem-solving abilities and experience in troubleshooting slotter machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Include a section on your resume that demonstrates your commitment to safety and continuous improvement.

Essential Experience Highlights for a Strong Slotter Operator Resume

- Operate and set up slotter machines to produce precision parts according to specifications.

- Read and interpret blueprints and technical drawings to ensure proper machine setup.

- Handle and secure materials safely, ensuring proper alignment and positioning.

- Inspect finished parts for quality and accuracy, using measuring tools and gauges.

- Perform preventive maintenance and troubleshoot machine issues to minimize downtime.

- Maintain a clean and organized work area, adhering to safety regulations.

- Coordinate with other team members to ensure smooth production flow.

Frequently Asked Questions (FAQ’s) For Slotter Operator

What is the primary function of a Slotter Operator?

The primary function of a Slotter Operator is to operate and maintain slotter machines to produce precision parts according to specifications.

What are the key skills required to be a successful Slotter Operator?

Key skills for a Slotter Operator include blueprint reading, measurement tools, quality control techniques, problem-solving, and preventive maintenance.

Is CNC programming a common requirement for Slotter Operators?

CNC programming may be a requirement for some Slotter Operator positions, but it may vary depending on the industry and specific job description.

What is the average salary for a Slotter Operator?

The average salary for a Slotter Operator varies depending on factors such as experience, location, and industry, but can range from $20,000 to $50,000 per year.

What are the career advancement opportunities for Slotter Operators?

Slotter Operators can advance their careers by gaining experience, developing new skills, and taking on leadership roles. Some potential career paths include Supervisor, Production Manager, or Manufacturing Engineer.

How can I prepare for a job interview as a Slotter Operator?

To prepare for a job interview as a Slotter Operator, research the company, practice answering common interview questions, and highlight your relevant skills and experience.

What are the safety regulations that Slotter Operators must adhere to?

Slotter Operators must adhere to safety regulations such as wearing personal protective equipment, maintaining a clean work area, and following proper machine operation procedures.