Are you a seasoned Sodder seeking a new career path? Discover our professionally built Sodder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

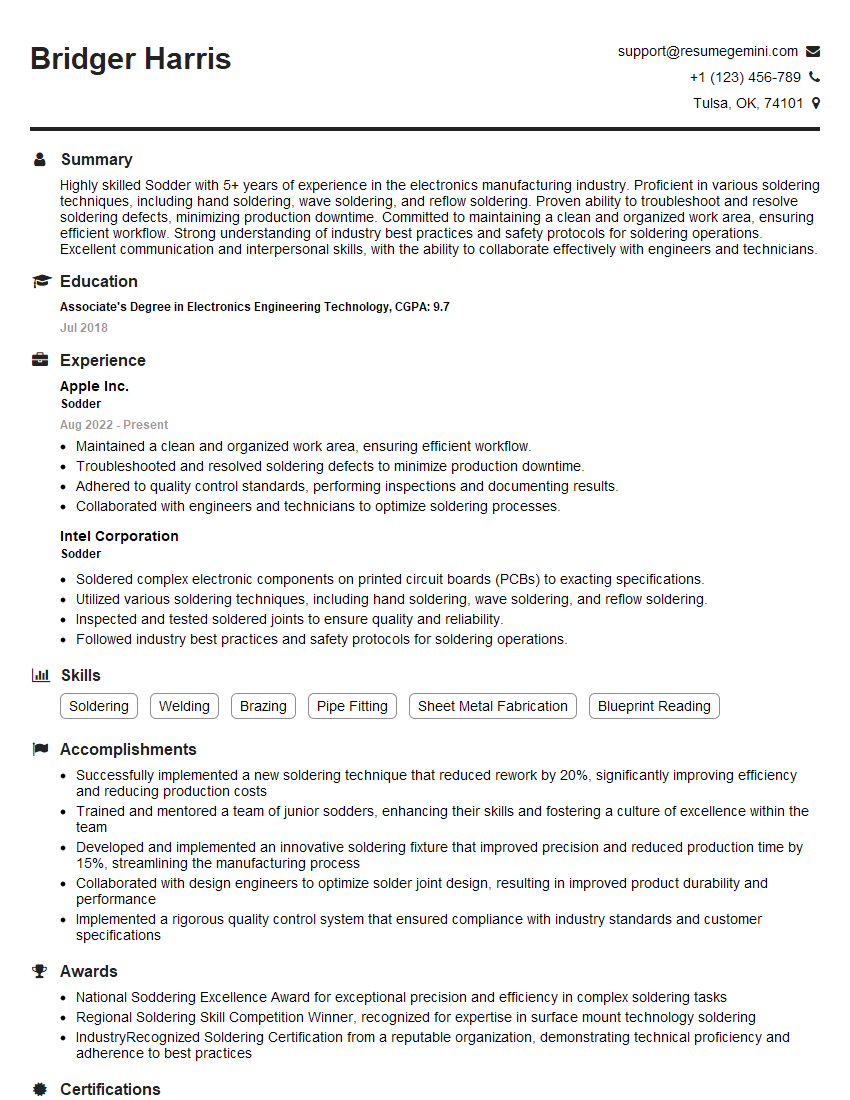

Bridger Harris

Sodder

Summary

Highly skilled Sodder with 5+ years of experience in the electronics manufacturing industry. Proficient in various soldering techniques, including hand soldering, wave soldering, and reflow soldering. Proven ability to troubleshoot and resolve soldering defects, minimizing production downtime. Committed to maintaining a clean and organized work area, ensuring efficient workflow. Strong understanding of industry best practices and safety protocols for soldering operations. Excellent communication and interpersonal skills, with the ability to collaborate effectively with engineers and technicians.

Education

Associate’s Degree in Electronics Engineering Technology

July 2018

Skills

- Soldering

- Welding

- Brazing

- Pipe Fitting

- Sheet Metal Fabrication

- Blueprint Reading

Work Experience

Sodder

- Maintained a clean and organized work area, ensuring efficient workflow.

- Troubleshooted and resolved soldering defects to minimize production downtime.

- Adhered to quality control standards, performing inspections and documenting results.

- Collaborated with engineers and technicians to optimize soldering processes.

Sodder

- Soldered complex electronic components on printed circuit boards (PCBs) to exacting specifications.

- Utilized various soldering techniques, including hand soldering, wave soldering, and reflow soldering.

- Inspected and tested soldered joints to ensure quality and reliability.

- Followed industry best practices and safety protocols for soldering operations.

Accomplishments

- Successfully implemented a new soldering technique that reduced rework by 20%, significantly improving efficiency and reducing production costs

- Trained and mentored a team of junior sodders, enhancing their skills and fostering a culture of excellence within the team

- Developed and implemented an innovative soldering fixture that improved precision and reduced production time by 15%, streamlining the manufacturing process

- Collaborated with design engineers to optimize solder joint design, resulting in improved product durability and performance

- Implemented a rigorous quality control system that ensured compliance with industry standards and customer specifications

Awards

- National Soddering Excellence Award for exceptional precision and efficiency in complex soldering tasks

- Regional Soldering Skill Competition Winner, recognized for expertise in surface mount technology soldering

- IndustryRecognized Soldering Certification from a reputable organization, demonstrating technical proficiency and adherence to best practices

Certificates

- Certified Soldering Technician (CST)

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certifications

- Occupational Safety and Health Administration (OSHA) Certifications

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sodder

- Highlight your skills and experience in different soldering techniques.

- Quantify your accomplishments whenever possible.

- Use keywords that are relevant to the job you’re applying for.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Sodder Resume

- Soldered complex electronic components on printed circuit boards (PCBs) to exacting specifications.

- Utilized various soldering techniques, including hand soldering, wave soldering, and reflow soldering.

- Inspected and tested soldered joints to ensure quality and reliability.

- Followed industry best practices and safety protocols for soldering operations.

- Maintained a clean and organized work area, ensuring efficient workflow.

- Troubleshooted and resolved soldering defects to minimize production downtime.

- Adhered to quality control standards, performing inspections and documenting results.

- Collaborated with engineers and technicians to optimize soldering processes.

Frequently Asked Questions (FAQ’s) For Sodder

What are the different types of soldering techniques?

The three main types of soldering techniques are hand soldering, wave soldering, and reflow soldering.

What are the safety protocols that must be followed when soldering?

The safety protocols that must be followed when soldering include wearing appropriate protective gear, such as safety glasses and gloves, and working in a well-ventilated area.

What are the common defects that can occur during soldering?

The common defects that can occur during soldering include solder bridges, cold joints, and solder balls.

What are the steps involved in troubleshooting a soldering defect?

The steps involved in troubleshooting a soldering defect include identifying the defect, determining the cause of the defect, and taking corrective action.

What are the key qualities of a good sodder?

The key qualities of a good sodder include good wetting ability, high strength, and low melting point.

What are some tips for writing a standout sodder resume?

Tips for writing a standout sodder resume include highlighting your skills and experience in different soldering techniques, quantifying your accomplishments whenever possible, using keywords that are relevant to the job you’re applying for, and proofreading your resume carefully for any errors.

What is the difference between a sodder and a welder?

A sodder is a metal alloy that is used to join two pieces of metal together, while a welder is a tool that is used to melt metal.

What are the different types of welding?

The different types of welding include arc welding, gas welding, and resistance welding.