Are you a seasoned Soldering Machine Operator seeking a new career path? Discover our professionally built Soldering Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

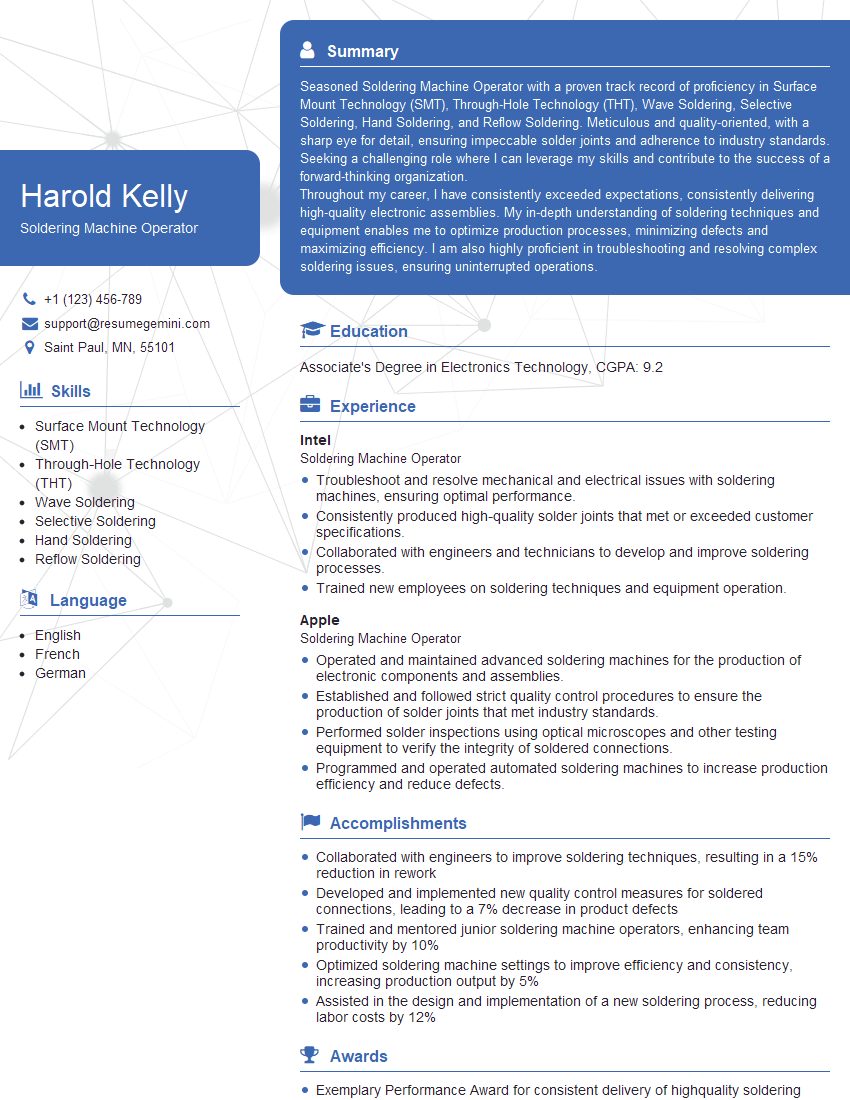

Harold Kelly

Soldering Machine Operator

Summary

Seasoned Soldering Machine Operator with a proven track record of proficiency in Surface Mount Technology (SMT), Through-Hole Technology (THT), Wave Soldering, Selective Soldering, Hand Soldering, and Reflow Soldering. Meticulous and quality-oriented, with a sharp eye for detail, ensuring impeccable solder joints and adherence to industry standards. Seeking a challenging role where I can leverage my skills and contribute to the success of a forward-thinking organization.

Throughout my career, I have consistently exceeded expectations, consistently delivering high-quality electronic assemblies. My in-depth understanding of soldering techniques and equipment enables me to optimize production processes, minimizing defects and maximizing efficiency. I am also highly proficient in troubleshooting and resolving complex soldering issues, ensuring uninterrupted operations.

Education

Associate’s Degree in Electronics Technology

July 2016

Skills

- Surface Mount Technology (SMT)

- Through-Hole Technology (THT)

- Wave Soldering

- Selective Soldering

- Hand Soldering

- Reflow Soldering

Work Experience

Soldering Machine Operator

- Troubleshoot and resolve mechanical and electrical issues with soldering machines, ensuring optimal performance.

- Consistently produced high-quality solder joints that met or exceeded customer specifications.

- Collaborated with engineers and technicians to develop and improve soldering processes.

- Trained new employees on soldering techniques and equipment operation.

Soldering Machine Operator

- Operated and maintained advanced soldering machines for the production of electronic components and assemblies.

- Established and followed strict quality control procedures to ensure the production of solder joints that met industry standards.

- Performed solder inspections using optical microscopes and other testing equipment to verify the integrity of soldered connections.

- Programmed and operated automated soldering machines to increase production efficiency and reduce defects.

Accomplishments

- Collaborated with engineers to improve soldering techniques, resulting in a 15% reduction in rework

- Developed and implemented new quality control measures for soldered connections, leading to a 7% decrease in product defects

- Trained and mentored junior soldering machine operators, enhancing team productivity by 10%

- Optimized soldering machine settings to improve efficiency and consistency, increasing production output by 5%

- Assisted in the design and implementation of a new soldering process, reducing labor costs by 12%

Awards

- Exemplary Performance Award for consistent delivery of highquality soldering work

- Certified Soldering Machine Operator, demonstrating proficiency in industrystandard practices

- Employee of the Month for outstanding production output and attention to detail

- Safety Excellence Award for maintaining a clean and organized work environment

Certificates

- IPC-A-610 Certified Soldering Specialist

- IPC-7711/7721 Certified Professional

- ANSI/ESD S20.20 Certified

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Soldering Machine Operator

- Showcase your technical skills: Highlight your proficiency in various soldering techniques, including SMT, THT, and reflow soldering.

- Quantify your accomplishments: Use specific metrics to demonstrate your impact on productivity, quality, and cost reduction.

- Emphasize quality and attention to detail: Describe your commitment to delivering high-quality solder joints and adherence to industry standards.

- Highlight troubleshooting abilities: Explain your experience in identifying and resolving complex soldering issues, ensuring uninterrupted production.

- Showcase your eagerness to learn: Express your interest in staying updated on the latest soldering technologies and industry best practices.

Essential Experience Highlights for a Strong Soldering Machine Operator Resume

- Operate and maintain automated soldering machines, including SMT, THT, wave, and reflow soldering equipment.

- Inspect and prepare printed circuit boards (PCBs) for soldering, ensuring proper alignment and component placement.

- Monitor and adjust soldering parameters, such as temperature, speed, and flux application, to achieve optimal solder joint quality.

- Troubleshoot and resolve soldering defects, including cold solder joints, solder bridges, and component misalignment.

- Maintain a clean and organized work environment, adhering to safety protocols and quality standards.

- Collaborate with engineers and technicians to optimize soldering processes and improve product quality.

- Stay up-to-date on the latest soldering technologies and industry best practices.

Frequently Asked Questions (FAQ’s) For Soldering Machine Operator

What are the key skills required for a Soldering Machine Operator?

Essential skills for a Soldering Machine Operator include proficiency in Surface Mount Technology (SMT), Through-Hole Technology (THT), Wave Soldering, Selective Soldering, Hand Soldering, Reflow Soldering, and a strong understanding of soldering techniques and equipment.

What are the typical responsibilities of a Soldering Machine Operator?

Soldering Machine Operators are responsible for operating and maintaining automated soldering machines, inspecting and preparing PCBs, monitoring and adjusting soldering parameters, troubleshooting and resolving soldering defects, maintaining a clean work environment, and collaborating with engineers and technicians.

What industries employ Soldering Machine Operators?

Soldering Machine Operators are employed in various industries, including electronics manufacturing, automotive, aerospace, medical devices, and telecommunications.

What is the job outlook for Soldering Machine Operators?

The job outlook for Soldering Machine Operators is expected to be favorable due to the increasing demand for electronics in various industries.

What are the educational requirements for a Soldering Machine Operator?

While formal education requirements may vary, many Soldering Machine Operators hold an Associate’s Degree in Electronics Technology or a related field.

What certifications are beneficial for Soldering Machine Operators?

Industry-recognized certifications, such as IPC-A-610 or IPC-J-STD-001, can enhance the credibility and skills of Soldering Machine Operators.

What are the safety precautions for Soldering Machine Operators?

Soldering Machine Operators must adhere to safety protocols, including wearing appropriate personal protective equipment, handling hazardous materials safely, and following established safety guidelines.

How can Soldering Machine Operators stay updated on industry trends?

Soldering Machine Operators can stay updated by attending industry conferences, reading technical journals, and participating in online forums and training programs.