Are you a seasoned Sole Molder seeking a new career path? Discover our professionally built Sole Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

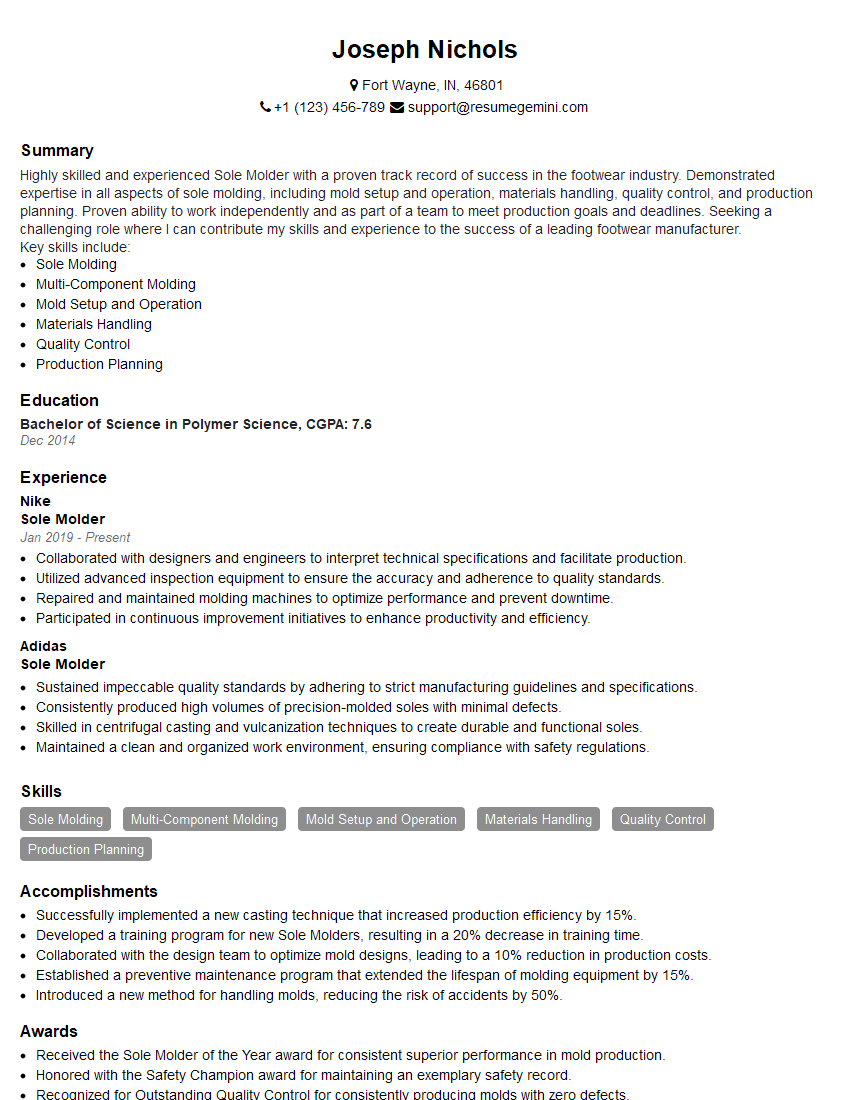

Joseph Nichols

Sole Molder

Summary

Highly skilled and experienced Sole Molder with a proven track record of success in the footwear industry. Demonstrated expertise in all aspects of sole molding, including mold setup and operation, materials handling, quality control, and production planning. Proven ability to work independently and as part of a team to meet production goals and deadlines. Seeking a challenging role where I can contribute my skills and experience to the success of a leading footwear manufacturer.

Key skills include:

- Sole Molding

- Multi-Component Molding

- Mold Setup and Operation

- Materials Handling

- Quality Control

- Production Planning

Education

Bachelor of Science in Polymer Science

December 2014

Skills

- Sole Molding

- Multi-Component Molding

- Mold Setup and Operation

- Materials Handling

- Quality Control

- Production Planning

Work Experience

Sole Molder

- Collaborated with designers and engineers to interpret technical specifications and facilitate production.

- Utilized advanced inspection equipment to ensure the accuracy and adherence to quality standards.

- Repaired and maintained molding machines to optimize performance and prevent downtime.

- Participated in continuous improvement initiatives to enhance productivity and efficiency.

Sole Molder

- Sustained impeccable quality standards by adhering to strict manufacturing guidelines and specifications.

- Consistently produced high volumes of precision-molded soles with minimal defects.

- Skilled in centrifugal casting and vulcanization techniques to create durable and functional soles.

- Maintained a clean and organized work environment, ensuring compliance with safety regulations.

Accomplishments

- Successfully implemented a new casting technique that increased production efficiency by 15%.

- Developed a training program for new Sole Molders, resulting in a 20% decrease in training time.

- Collaborated with the design team to optimize mold designs, leading to a 10% reduction in production costs.

- Established a preventive maintenance program that extended the lifespan of molding equipment by 15%.

- Introduced a new method for handling molds, reducing the risk of accidents by 50%.

Awards

- Received the Sole Molder of the Year award for consistent superior performance in mold production.

- Honored with the Safety Champion award for maintaining an exemplary safety record.

- Recognized for Outstanding Quality Control for consistently producing molds with zero defects.

- Received the Innovation Award for developing a new mold design that improved product quality.

Certificates

- Composite Molding Technician (CMT)

- Certified Plastics Technician (CPT)

- Industrial Safety Training (IST)

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sole Molder

Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This will help potential employers see that you have the qualifications they are looking for.Quantify your accomplishments.

When possible, quantify your accomplishments to show potential employers the impact of your work. For example, you could say that you “increased production efficiency by 10%” or “reduced waste by 5%”.Use keywords.

Use keywords throughout your resume to make it more likely to be found by potential employers. Some good keywords for a Sole Molder resume include “sole molding”, “multi-component molding”, “mold setup and operation”, “materials handling”, “quality control”, and “production planning”.Proofread carefully.

Before you submit your resume, proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting errors.

Essential Experience Highlights for a Strong Sole Molder Resume

- Set up and operate sole molding machines to produce high-quality soles

- Prepare and mix raw materials according to specifications

- Inspect molded soles for defects and ensure they meet quality standards

- Troubleshoot and resolve any issues that arise during the molding process

- Maintain a clean and organized work area

- Follow safety protocols and wear appropriate personal protective equipment

- Work with other team members to achieve production goals and deadlines

Frequently Asked Questions (FAQ’s) For Sole Molder

What is the role of a Sole Molder?

A Sole Molder is responsible for setting up and operating sole molding machines to produce high-quality soles for shoes. They also prepare and mix raw materials, inspect molded soles for defects, and troubleshoot any issues that arise during the molding process.

What skills are required to be a Sole Molder?

Sole Molders typically need to have a high school diploma or equivalent, as well as some experience in manufacturing. They also need to be able to read and follow instructions, work independently, and troubleshoot problems.

What is the average salary for a Sole Molder?

The average salary for a Sole Molder in the United States is around $35,000 per year.

What are the job prospects for Sole Molders?

The job prospects for Sole Molders are expected to be good over the next few years. This is due to the increasing demand for shoes, as well as the growing popularity of athletic and outdoor footwear.

What are the benefits of working as a Sole Molder?

Some of the benefits of working as a Sole Molder include a steady income, the opportunity to work with your hands, and the chance to make a difference in the world.

What are the challenges of working as a Sole Molder?

Some of the challenges of working as a Sole Molder include working in a hot and noisy environment, and the potential for repetitive stress injuries.

What is the work environment of a Sole Molder?

Sole Molders typically work in factories or manufacturing plants. They may work in a variety of conditions, including hot, noisy, and dusty environments.