Are you a seasoned Spline Rolling Machine Job Setter seeking a new career path? Discover our professionally built Spline Rolling Machine Job Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

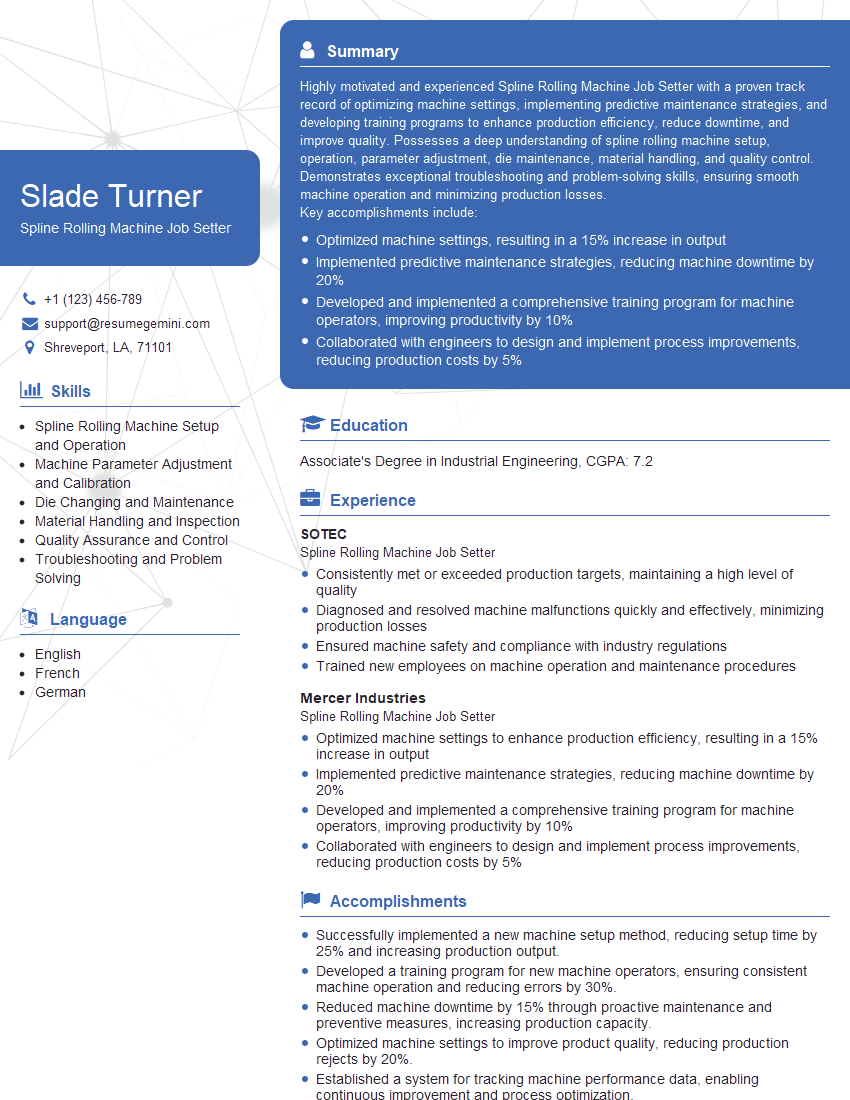

Slade Turner

Spline Rolling Machine Job Setter

Summary

Highly motivated and experienced Spline Rolling Machine Job Setter with a proven track record of optimizing machine settings, implementing predictive maintenance strategies, and developing training programs to enhance production efficiency, reduce downtime, and improve quality. Possesses a deep understanding of spline rolling machine setup, operation, parameter adjustment, die maintenance, material handling, and quality control. Demonstrates exceptional troubleshooting and problem-solving skills, ensuring smooth machine operation and minimizing production losses.

Key accomplishments include:

- Optimized machine settings, resulting in a 15% increase in output

- Implemented predictive maintenance strategies, reducing machine downtime by 20%

- Developed and implemented a comprehensive training program for machine operators, improving productivity by 10%

- Collaborated with engineers to design and implement process improvements, reducing production costs by 5%

Education

Associate’s Degree in Industrial Engineering

May 2015

Skills

- Spline Rolling Machine Setup and Operation

- Machine Parameter Adjustment and Calibration

- Die Changing and Maintenance

- Material Handling and Inspection

- Quality Assurance and Control

- Troubleshooting and Problem Solving

Work Experience

Spline Rolling Machine Job Setter

- Consistently met or exceeded production targets, maintaining a high level of quality

- Diagnosed and resolved machine malfunctions quickly and effectively, minimizing production losses

- Ensured machine safety and compliance with industry regulations

- Trained new employees on machine operation and maintenance procedures

Spline Rolling Machine Job Setter

- Optimized machine settings to enhance production efficiency, resulting in a 15% increase in output

- Implemented predictive maintenance strategies, reducing machine downtime by 20%

- Developed and implemented a comprehensive training program for machine operators, improving productivity by 10%

- Collaborated with engineers to design and implement process improvements, reducing production costs by 5%

Accomplishments

- Successfully implemented a new machine setup method, reducing setup time by 25% and increasing production output.

- Developed a training program for new machine operators, ensuring consistent machine operation and reducing errors by 30%.

- Reduced machine downtime by 15% through proactive maintenance and preventive measures, increasing production capacity.

- Optimized machine settings to improve product quality, reducing production rejects by 20%.

- Established a system for tracking machine performance data, enabling continuous improvement and process optimization.

Awards

- Won the Spline Rolling Machine Job Setter of the Year award for outstanding performance in spline rolling machine setup and operation.

- Received the Safety Excellence Award for consistently maintaining a safe work environment and adhering to all safety protocols.

- Recognized with the Innovation Award for developing and implementing a new technique that significantly improved machine efficiency.

Certificates

- Certified Spline Rolling Machine Operator

- ISO 9001 Quality Management System

- OSHA Safety Certification

- PMP (Project Management Professional)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Spline Rolling Machine Job Setter

Highlight your technical skills and knowledge.

Emphasize your expertise in spline rolling machine setup, operation, and maintenance.Quantify your accomplishments.

Use specific metrics to demonstrate the impact of your work, such as increased production efficiency, reduced downtime, or improved quality.Showcase your problem-solving abilities.

Describe your experience in troubleshooting and resolving machine malfunctions, highlighting your ability to identify root causes and implement effective solutions.Demonstrate your commitment to safety.

Emphasize your adherence to industry regulations and safety protocols to ensure a safe work environment.

Essential Experience Highlights for a Strong Spline Rolling Machine Job Setter Resume

- Set up, operate, and maintain spline rolling machines to produce high-quality splines according to specifications.

- Adjust machine parameters, calibrate sensors, and perform preventive maintenance to ensure optimal machine performance.

- Change and maintain dies, monitor material flow, and inspect finished products to ensure quality standards are met.

- Troubleshoot and resolve machine malfunctions, identify root causes, and implement corrective actions to minimize downtime.

- Develop and implement training programs for machine operators to improve their skills and knowledge.

- Maintain a clean and safe work environment, adhering to industry regulations and safety protocols.

Frequently Asked Questions (FAQ’s) For Spline Rolling Machine Job Setter

What are the primary responsibilities of a Spline Rolling Machine Job Setter?

The primary responsibilities of a Spline Rolling Machine Job Setter include setting up, operating, and maintaining spline rolling machines; adjusting machine parameters and calibrating sensors; changing and maintaining dies; monitoring material flow; inspecting finished products; troubleshooting and resolving machine malfunctions; and developing and implementing training programs for machine operators.

What qualifications are required to become a Spline Rolling Machine Job Setter?

Typically, a high school diploma or equivalent is required to become a Spline Rolling Machine Job Setter. Some employers may prefer candidates with an Associate’s Degree in Industrial Engineering or a related field.

What are the career prospects for a Spline Rolling Machine Job Setter?

With experience and additional training, Spline Rolling Machine Job Setters can advance to positions such as Production Supervisor, Maintenance Technician, or Quality Control Inspector.

What are the key skills required for a Spline Rolling Machine Job Setter?

Key skills required for a Spline Rolling Machine Job Setter include machine setup and operation, parameter adjustment and calibration, die changing and maintenance, material handling and inspection, quality assurance and control, troubleshooting and problem solving, and safety compliance.

What is the work environment like for a Spline Rolling Machine Job Setter?

Spline Rolling Machine Job Setters typically work in manufacturing environments, operating and maintaining spline rolling machines. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the safety precautions that Spline Rolling Machine Job Setters must follow?

Spline Rolling Machine Job Setters must follow established safety protocols to minimize the risk of accidents. These protocols may include wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards in the work environment.

How can I prepare for a career as a Spline Rolling Machine Job Setter?

To prepare for a career as a Spline Rolling Machine Job Setter, you can obtain a high school diploma or equivalent, consider pursuing an Associate’s Degree in Industrial Engineering or a related field, and develop skills in machine setup and operation, parameter adjustment and calibration, die changing and maintenance, and troubleshooting and problem solving.