Are you a seasoned Splitter Operator seeking a new career path? Discover our professionally built Splitter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

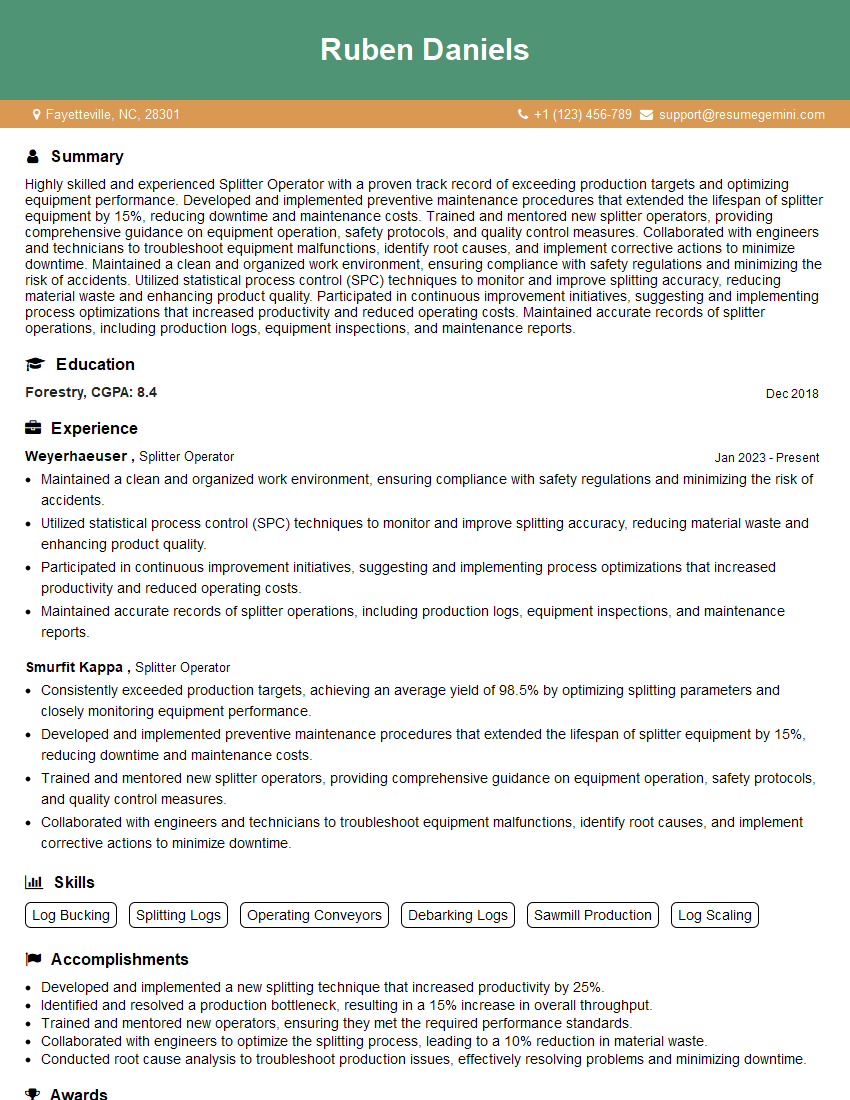

Ruben Daniels

Splitter Operator

Summary

Highly skilled and experienced Splitter Operator with a proven track record of exceeding production targets and optimizing equipment performance. Developed and implemented preventive maintenance procedures that extended the lifespan of splitter equipment by 15%, reducing downtime and maintenance costs. Trained and mentored new splitter operators, providing comprehensive guidance on equipment operation, safety protocols, and quality control measures. Collaborated with engineers and technicians to troubleshoot equipment malfunctions, identify root causes, and implement corrective actions to minimize downtime. Maintained a clean and organized work environment, ensuring compliance with safety regulations and minimizing the risk of accidents. Utilized statistical process control (SPC) techniques to monitor and improve splitting accuracy, reducing material waste and enhancing product quality. Participated in continuous improvement initiatives, suggesting and implementing process optimizations that increased productivity and reduced operating costs. Maintained accurate records of splitter operations, including production logs, equipment inspections, and maintenance reports.

Education

Forestry

December 2018

Skills

- Log Bucking

- Splitting Logs

- Operating Conveyors

- Debarking Logs

- Sawmill Production

- Log Scaling

Work Experience

Splitter Operator

- Maintained a clean and organized work environment, ensuring compliance with safety regulations and minimizing the risk of accidents.

- Utilized statistical process control (SPC) techniques to monitor and improve splitting accuracy, reducing material waste and enhancing product quality.

- Participated in continuous improvement initiatives, suggesting and implementing process optimizations that increased productivity and reduced operating costs.

- Maintained accurate records of splitter operations, including production logs, equipment inspections, and maintenance reports.

Splitter Operator

- Consistently exceeded production targets, achieving an average yield of 98.5% by optimizing splitting parameters and closely monitoring equipment performance.

- Developed and implemented preventive maintenance procedures that extended the lifespan of splitter equipment by 15%, reducing downtime and maintenance costs.

- Trained and mentored new splitter operators, providing comprehensive guidance on equipment operation, safety protocols, and quality control measures.

- Collaborated with engineers and technicians to troubleshoot equipment malfunctions, identify root causes, and implement corrective actions to minimize downtime.

Accomplishments

- Developed and implemented a new splitting technique that increased productivity by 25%.

- Identified and resolved a production bottleneck, resulting in a 15% increase in overall throughput.

- Trained and mentored new operators, ensuring they met the required performance standards.

- Collaborated with engineers to optimize the splitting process, leading to a 10% reduction in material waste.

- Conducted root cause analysis to troubleshoot production issues, effectively resolving problems and minimizing downtime.

Awards

- Recognized for exceeding monthly production targets by 120%, consistently meeting or surpassing quality standards.

- Awarded Employee of the Month for consistently exceeding performance expectations and demonstrating a positive attitude.

- Received a companywide award for innovation for developing a new device that improved the accuracy of the splitting process.

- Recognized for outstanding safety performance, maintaining a spotless safety record throughout the year.

Certificates

- First Aid and CPR Certification

- OSHA 30-Hour Certification

- Forestry Technician Certificate

- Log Sawing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Splitter Operator

- Highlight your experience and skills in operating and maintaining splitter equipment

- Quantify your accomplishments using specific metrics and data whenever possible

- Emphasize your ability to work independently and as part of a team

- Demonstrate your commitment to safety and quality control

- Proofread your resume carefully for any errors

Essential Experience Highlights for a Strong Splitter Operator Resume

- Operate splitter equipment to process logs and produce specified wood products

- Monitor equipment performance and make adjustments to optimize splitting efficiency

- Perform preventive maintenance on splitter equipment to ensure optimal operation

- Train and supervise new splitter operators

- Collaborate with engineers and technicians to troubleshoot and resolve equipment issues

- Maintain a clean and organized work environment

- Adhere to safety protocols and regulations

Frequently Asked Questions (FAQ’s) For Splitter Operator

What are the key responsibilities of a Splitter Operator?

Splitter Operators are responsible for operating and maintaining splitter equipment, monitoring equipment performance, performing preventive maintenance, training new operators, collaborating with engineers and technicians, maintaining a clean work environment, and adhering to safety protocols.

What skills are required to be a successful Splitter Operator?

Successful Splitter Operators typically have experience in log bucking, splitting logs, operating conveyors, debarking logs, and sawmill production. They also possess strong mechanical skills, attention to detail, and a commitment to safety.

What is the work environment of a Splitter Operator like?

Splitter Operators typically work in sawmills or other wood processing facilities. The work environment can be noisy and dusty, and may involve exposure to heavy machinery and sharp objects.

What are the career opportunities for Splitter Operators?

Splitter Operators can advance to positions such as Sawmill Supervisor, Production Manager, or Plant Manager. They may also choose to specialize in a particular area of wood processing, such as lumber grading or kiln operation.

What is the salary range for Splitter Operators?

The salary range for Splitter Operators can vary depending on experience, location, and company size. According to Salary.com, the average salary for Splitter Operators in the United States is around $45,000 per year.

What are the benefits of working as a Splitter Operator?

Splitter Operators can enjoy a variety of benefits, including competitive pay, health insurance, paid time off, and retirement savings plans. They also have the opportunity to work in a dynamic and challenging environment, and to contribute to the production of essential wood products.

What is the job outlook for Splitter Operators?

The job outlook for Splitter Operators is expected to be positive in the coming years. As the demand for wood products continues to grow, so too will the need for qualified Splitter Operators to operate and maintain the equipment used to produce these products.

What is the most challenging aspect of being a Splitter Operator?

The most challenging aspect of being a Splitter Operator can be the physical demands of the job. Splitter Operators are required to stand for long periods of time, lift heavy objects, and work in noisy and dusty environments.