Are you a seasoned Spray Operator seeking a new career path? Discover our professionally built Spray Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

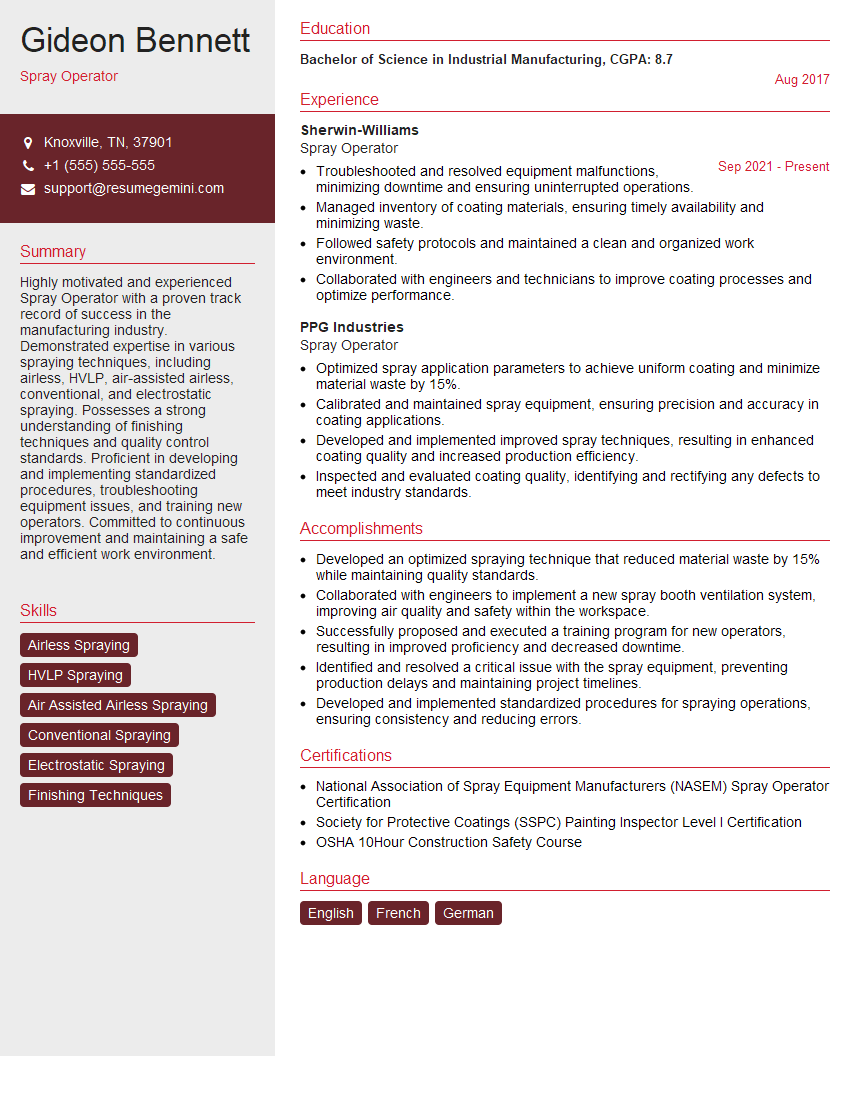

Gideon Bennett

Spray Operator

Summary

Highly motivated and experienced Spray Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in various spraying techniques, including airless, HVLP, air-assisted airless, conventional, and electrostatic spraying. Possesses a strong understanding of finishing techniques and quality control standards. Proficient in developing and implementing standardized procedures, troubleshooting equipment issues, and training new operators. Committed to continuous improvement and maintaining a safe and efficient work environment.

Education

Bachelor of Science in Industrial Manufacturing

August 2017

Skills

- Airless Spraying

- HVLP Spraying

- Air Assisted Airless Spraying

- Conventional Spraying

- Electrostatic Spraying

- Finishing Techniques

Work Experience

Spray Operator

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and ensuring uninterrupted operations.

- Managed inventory of coating materials, ensuring timely availability and minimizing waste.

- Followed safety protocols and maintained a clean and organized work environment.

- Collaborated with engineers and technicians to improve coating processes and optimize performance.

Spray Operator

- Optimized spray application parameters to achieve uniform coating and minimize material waste by 15%.

- Calibrated and maintained spray equipment, ensuring precision and accuracy in coating applications.

- Developed and implemented improved spray techniques, resulting in enhanced coating quality and increased production efficiency.

- Inspected and evaluated coating quality, identifying and rectifying any defects to meet industry standards.

Accomplishments

- Developed an optimized spraying technique that reduced material waste by 15% while maintaining quality standards.

- Collaborated with engineers to implement a new spray booth ventilation system, improving air quality and safety within the workspace.

- Successfully proposed and executed a training program for new operators, resulting in improved proficiency and decreased downtime.

- Identified and resolved a critical issue with the spray equipment, preventing production delays and maintaining project timelines.

- Developed and implemented standardized procedures for spraying operations, ensuring consistency and reducing errors.

Certificates

- National Association of Spray Equipment Manufacturers (NASEM) Spray Operator Certification

- Society for Protective Coatings (SSPC) Painting Inspector Level I Certification

- OSHA 10Hour Construction Safety Course

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Spray Operator

- Quantify your accomplishments using specific metrics and data whenever possible.

- Highlight your knowledge of different spraying techniques and equipment.

- Emphasize your commitment to safety and your ability to work independently and as part of a team.

- Tailor your resume to the specific job requirements and company you are applying to.

Essential Experience Highlights for a Strong Spray Operator Resume

- Operate and maintain a variety of spraying equipment, including airless, HVLP, and electrostatic sprayers

- Apply coatings, paints, and other materials to surfaces according to specified requirements

- Follow established procedures and quality control standards to ensure optimal results

- Troubleshoot and resolve equipment issues promptly to minimize downtime

- Train and mentor new spray operators to ensure proficiency and adherence to best practices

- Maintain a clean and organized work area, ensuring compliance with safety regulations

Frequently Asked Questions (FAQ’s) For Spray Operator

What are the different types of spraying techniques?

There are several spraying techniques used in the manufacturing industry, including airless, HVLP, air-assisted airless, conventional, and electrostatic spraying. Each technique has its own advantages and is suitable for different applications.

What are the key skills required for a Spray Operator?

The key skills for a Spray Operator include proficiency in various spraying techniques, knowledge of finishing techniques, attention to detail, problem-solving abilities, and commitment to safety.

What are the safety precautions that should be taken when operating spraying equipment?

When operating spraying equipment, it is essential to wear appropriate personal protective equipment, including a respirator, gloves, and protective clothing. Proper ventilation is crucial, and the work area should be kept clean and free of flammable materials.

What are the career advancement opportunities for Spray Operators?

With experience and additional training, Spray Operators can advance to positions such as Quality Control Inspector, Production Supervisor, or Manufacturing Engineer.

What is the job outlook for Spray Operators?

The job outlook for Spray Operators is expected to be positive in the coming years due to the increasing demand for skilled manufacturing professionals.

What are the different industries that employ Spray Operators?

Spray Operators are employed in various industries, including automotive, aerospace, furniture manufacturing, and general manufacturing.