Are you a seasoned Squaring Machine Operator seeking a new career path? Discover our professionally built Squaring Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

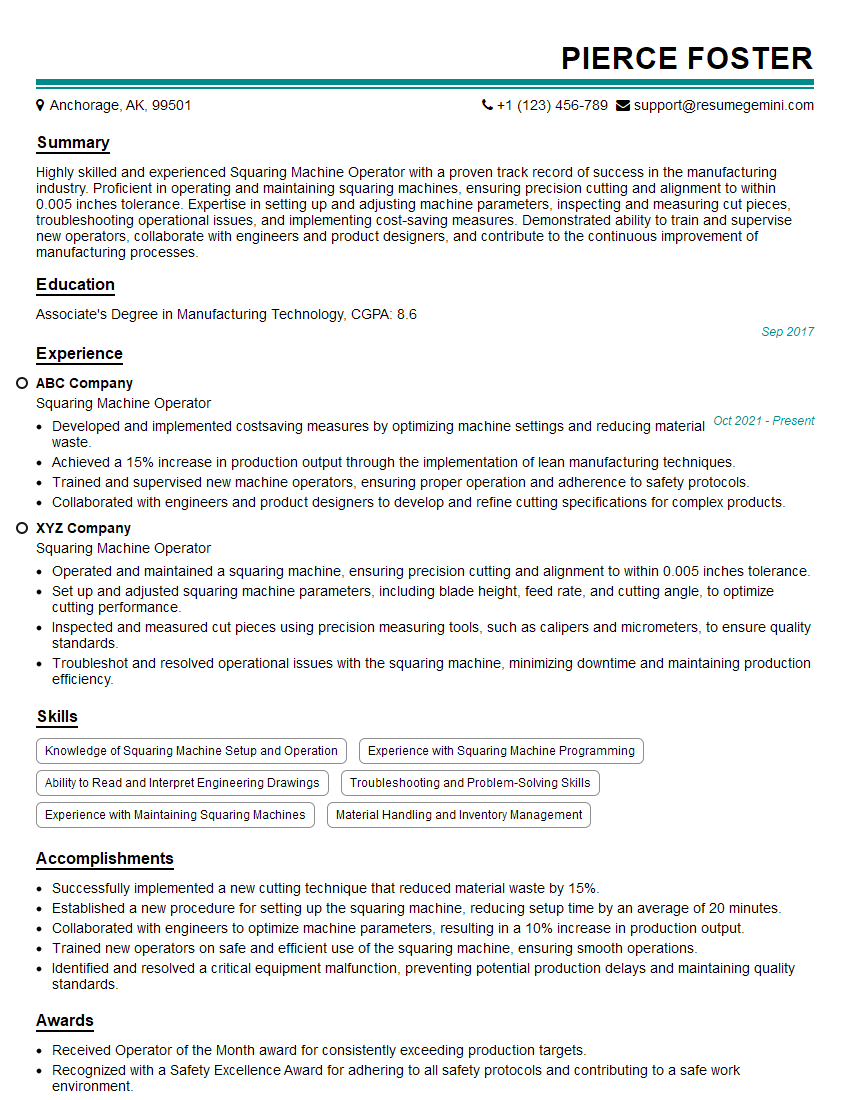

Pierce Foster

Squaring Machine Operator

Summary

Highly skilled and experienced Squaring Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining squaring machines, ensuring precision cutting and alignment to within 0.005 inches tolerance. Expertise in setting up and adjusting machine parameters, inspecting and measuring cut pieces, troubleshooting operational issues, and implementing cost-saving measures. Demonstrated ability to train and supervise new operators, collaborate with engineers and product designers, and contribute to the continuous improvement of manufacturing processes.

Education

Associate’s Degree in Manufacturing Technology

September 2017

Skills

- Knowledge of Squaring Machine Setup and Operation

- Experience with Squaring Machine Programming

- Ability to Read and Interpret Engineering Drawings

- Troubleshooting and Problem-Solving Skills

- Experience with Maintaining Squaring Machines

- Material Handling and Inventory Management

Work Experience

Squaring Machine Operator

- Developed and implemented costsaving measures by optimizing machine settings and reducing material waste.

- Achieved a 15% increase in production output through the implementation of lean manufacturing techniques.

- Trained and supervised new machine operators, ensuring proper operation and adherence to safety protocols.

- Collaborated with engineers and product designers to develop and refine cutting specifications for complex products.

Squaring Machine Operator

- Operated and maintained a squaring machine, ensuring precision cutting and alignment to within 0.005 inches tolerance.

- Set up and adjusted squaring machine parameters, including blade height, feed rate, and cutting angle, to optimize cutting performance.

- Inspected and measured cut pieces using precision measuring tools, such as calipers and micrometers, to ensure quality standards.

- Troubleshot and resolved operational issues with the squaring machine, minimizing downtime and maintaining production efficiency.

Accomplishments

- Successfully implemented a new cutting technique that reduced material waste by 15%.

- Established a new procedure for setting up the squaring machine, reducing setup time by an average of 20 minutes.

- Collaborated with engineers to optimize machine parameters, resulting in a 10% increase in production output.

- Trained new operators on safe and efficient use of the squaring machine, ensuring smooth operations.

- Identified and resolved a critical equipment malfunction, preventing potential production delays and maintaining quality standards.

Awards

- Received Operator of the Month award for consistently exceeding production targets.

- Recognized with a Safety Excellence Award for adhering to all safety protocols and contributing to a safe work environment.

- Awarded Employee of the Quarter for exceptional performance and dedication to the team.

Certificates

- OSHA Safety Certification

- Quality Control Certification

- Lean Manufacturing Certification

- ISO 9001 Lead Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Squaring Machine Operator

- Highlight your skills and experience in operating and maintaining squaring machines.

- Quantify your accomplishments with specific metrics, such as the 15% increase in production output.

- Showcase your problem-solving abilities and commitment to continuous improvement.

- Tailor your resume to the specific requirements of the job description.

Essential Experience Highlights for a Strong Squaring Machine Operator Resume

- Operate and maintain squaring machines to ensure precision cutting and alignment to within 0.005 inches tolerance.

- Set up and adjust squaring machine parameters, including blade height, feed rate, and cutting angle, to optimize cutting performance.

- Inspect and measure cut pieces using precision measuring tools, such as calipers and micrometers, to ensure quality standards.

- Troubleshoot and resolve operational issues with the squaring machine, minimizing downtime and maintaining production efficiency.

- Develop and implement cost-saving measures by optimizing machine settings and reducing material waste.

- Train and supervise new machine operators, ensuring proper operation and adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Squaring Machine Operator

What are the key skills required to be a successful Squaring Machine Operator?

Key skills include knowledge of squaring machine setup and operation, experience with squaring machine programming, ability to read and interpret engineering drawings, troubleshooting and problem-solving skills, experience with maintaining squaring machines, and material handling and inventory management.

What is the average salary for a Squaring Machine Operator?

The average salary for a Squaring Machine Operator in the United States is around $45,000 per year.

What are the career advancement opportunities for Squaring Machine Operators?

With experience and additional training, Squaring Machine Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or Manufacturing Engineer.

What are the safety precautions that Squaring Machine Operators should follow?

Squaring Machine Operators should always wear appropriate safety gear, including eye protection, earplugs, and gloves. They should also be trained on the proper operation of the machine and follow all safety protocols.

What are the common challenges faced by Squaring Machine Operators?

Common challenges include maintaining precision cutting and alignment, troubleshooting operational issues, and meeting production targets.

What are the latest trends in the Squaring Machine Operator industry?

The latest trends include the adoption of automated squaring machines, the use of advanced measuring and inspection technologies, and the implementation of lean manufacturing techniques.