Are you a seasoned Steel Fabricator seeking a new career path? Discover our professionally built Steel Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

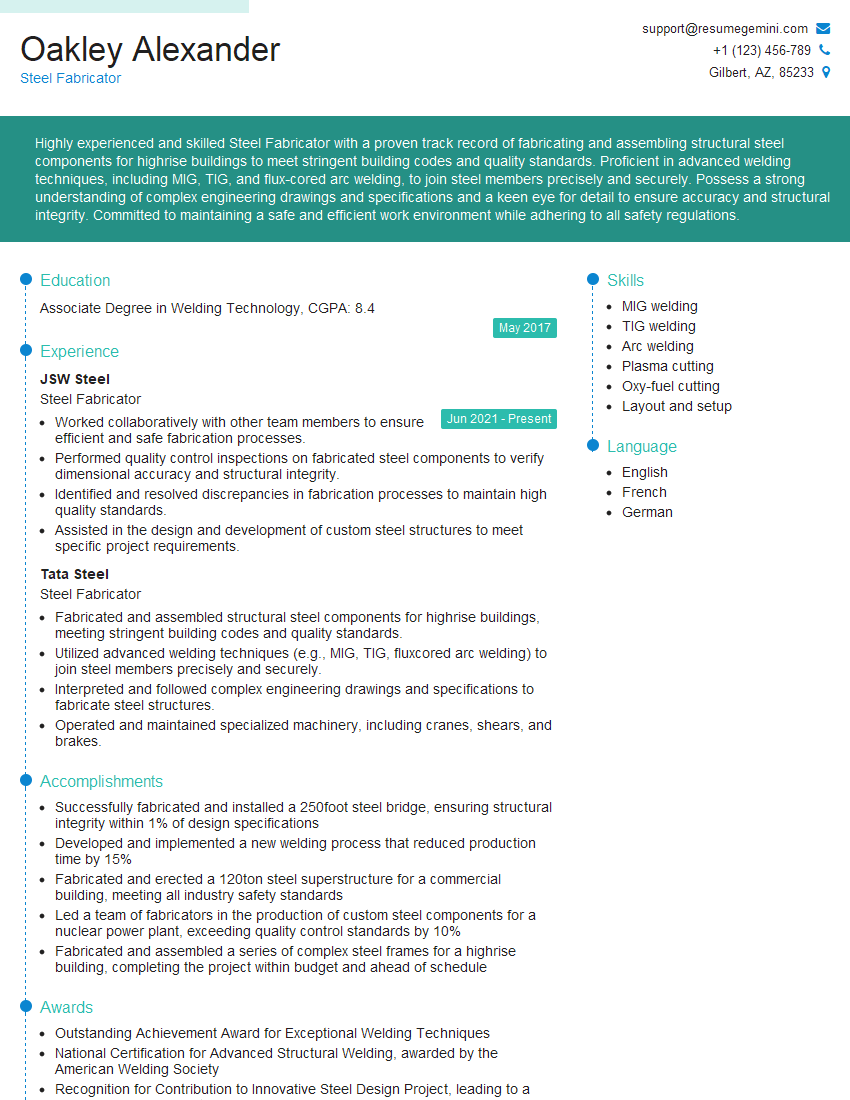

Oakley Alexander

Steel Fabricator

Summary

Highly experienced and skilled Steel Fabricator with a proven track record of fabricating and assembling structural steel components for highrise buildings to meet stringent building codes and quality standards. Proficient in advanced welding techniques, including MIG, TIG, and flux-cored arc welding, to join steel members precisely and securely. Possess a strong understanding of complex engineering drawings and specifications and a keen eye for detail to ensure accuracy and structural integrity. Committed to maintaining a safe and efficient work environment while adhering to all safety regulations.

Education

Associate Degree in Welding Technology

May 2017

Skills

- MIG welding

- TIG welding

- Arc welding

- Plasma cutting

- Oxy-fuel cutting

- Layout and setup

Work Experience

Steel Fabricator

- Worked collaboratively with other team members to ensure efficient and safe fabrication processes.

- Performed quality control inspections on fabricated steel components to verify dimensional accuracy and structural integrity.

- Identified and resolved discrepancies in fabrication processes to maintain high quality standards.

- Assisted in the design and development of custom steel structures to meet specific project requirements.

Steel Fabricator

- Fabricated and assembled structural steel components for highrise buildings, meeting stringent building codes and quality standards.

- Utilized advanced welding techniques (e.g., MIG, TIG, fluxcored arc welding) to join steel members precisely and securely.

- Interpreted and followed complex engineering drawings and specifications to fabricate steel structures.

- Operated and maintained specialized machinery, including cranes, shears, and brakes.

Accomplishments

- Successfully fabricated and installed a 250foot steel bridge, ensuring structural integrity within 1% of design specifications

- Developed and implemented a new welding process that reduced production time by 15%

- Fabricated and erected a 120ton steel superstructure for a commercial building, meeting all industry safety standards

- Led a team of fabricators in the production of custom steel components for a nuclear power plant, exceeding quality control standards by 10%

- Fabricated and assembled a series of complex steel frames for a highrise building, completing the project within budget and ahead of schedule

Awards

- Outstanding Achievement Award for Exceptional Welding Techniques

- National Certification for Advanced Structural Welding, awarded by the American Welding Society

- Recognition for Contribution to Innovative Steel Design Project, leading to a 20% increase in project efficiency

- Award of Excellence for Design and Fabrication of a Structural Steel Tower

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- NFPA 70E

- OSHA 30-Hour General Industry Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Fabricator

- Highlight your welding certifications and experience with different welding techniques.

- Showcase your knowledge of relevant industry codes and standards, such as AWS D1.1.

- Quantify your accomplishments by providing specific examples of projects you’ve worked on.

- Emphasize your teamwork and communication skills, as collaboration is crucial in fabrication environments.

- Include a section on your resume that demonstrates your understanding of safety protocols and regulations.

Essential Experience Highlights for a Strong Steel Fabricator Resume

- Fabricated structural steel components for high-rise buildings, bridges, and other??structures.

- Assembled steel members using advanced welding techniques, including MIG, TIG, and flux-cored arc welding.

- Interpreted and followed complex engineering drawings and specifications to ensure accuracy and precision.

- Inspected and ensured the quality and integrity of fabricated steel components.

- Maintained and operated specialized machinery, including cranes, shears, and brakes.

- Collaborated with other team members to ensure efficient and safe fabrication processes.

- Troubleshooted and resolved discrepancies in fabrication processes to maintain high standards.

Frequently Asked Questions (FAQ’s) For Steel Fabricator

What is the primary role of a Steel Fabricator?

A Steel Fabricator is responsible for cutting, shaping, welding, and assembling structural steel components used in the construction of buildings, bridges, and other structures.

What skills are essential for a Steel Fabricator?

Essential skills for a Steel Fabricator include proficiency in welding techniques, blueprint reading, knowledge of industry codes and standards, and the ability to operate specialized machinery.

What are the different welding techniques used by Steel Fabricators?

Common welding techniques used by Steel Fabricators include MIG welding, TIG welding, and flux-cored arc welding.

What safety precautions should Steel Fabricators follow?

Steel Fabricators must adhere to strict safety protocols, including wearing appropriate protective gear, maintaining a clean and organized work area, and following proper lifting techniques.

What career advancement opportunities are there for Steel Fabricators?

Experienced Steel Fabricators can advance to supervisory roles, such as Welding Foreman or Fabrication Manager, or specialize in areas such as welding inspection or welding engineering.

What industries hire Steel Fabricators?

Steel Fabricators are employed in various industries, including construction, manufacturing, shipbuilding, and transportation.

What are the educational requirements to become a Steel Fabricator?

While formal education is not always required, many Steel Fabricators have an associate degree or certification in welding technology or a related field.