Are you a seasoned Steel Hanger seeking a new career path? Discover our professionally built Steel Hanger Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

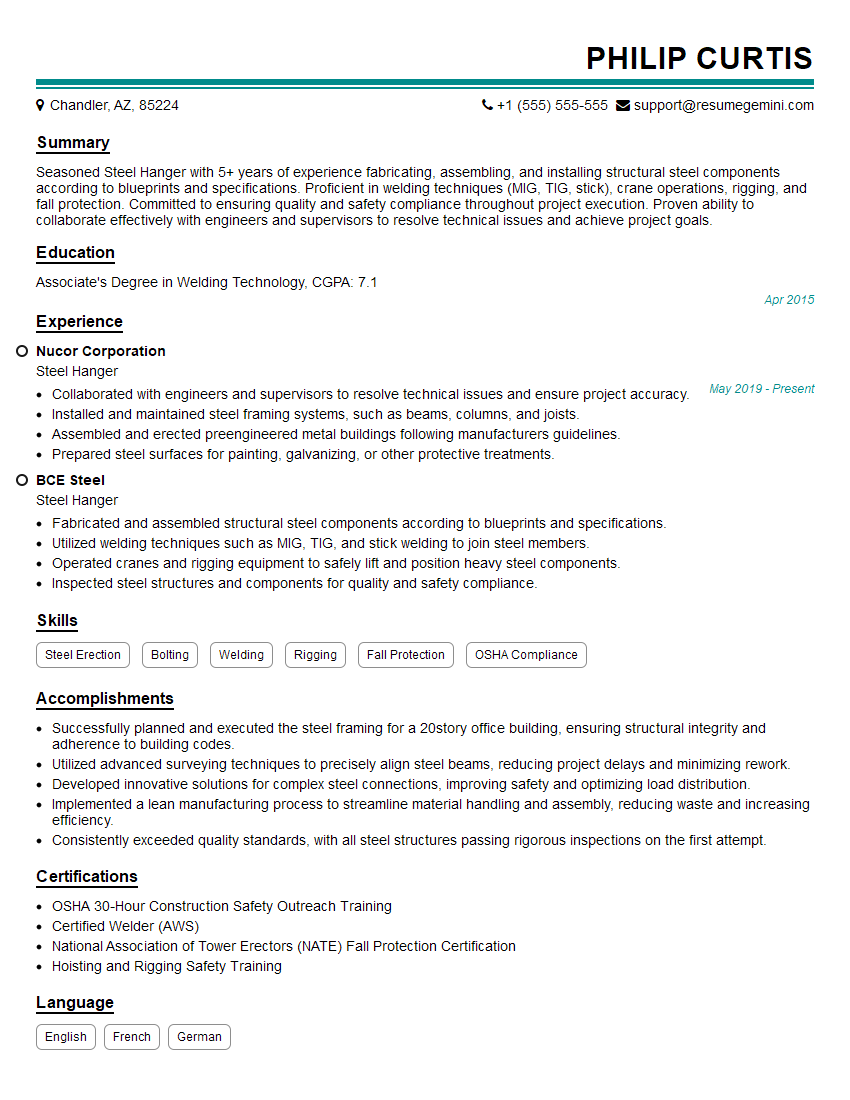

Philip Curtis

Steel Hanger

Summary

Seasoned Steel Hanger with 5+ years of experience fabricating, assembling, and installing structural steel components according to blueprints and specifications. Proficient in welding techniques (MIG, TIG, stick), crane operations, rigging, and fall protection. Committed to ensuring quality and safety compliance throughout project execution. Proven ability to collaborate effectively with engineers and supervisors to resolve technical issues and achieve project goals.

Education

Associate’s Degree in Welding Technology

April 2015

Skills

- Steel Erection

- Bolting

- Welding

- Rigging

- Fall Protection

- OSHA Compliance

Work Experience

Steel Hanger

- Collaborated with engineers and supervisors to resolve technical issues and ensure project accuracy.

- Installed and maintained steel framing systems, such as beams, columns, and joists.

- Assembled and erected preengineered metal buildings following manufacturers guidelines.

- Prepared steel surfaces for painting, galvanizing, or other protective treatments.

Steel Hanger

- Fabricated and assembled structural steel components according to blueprints and specifications.

- Utilized welding techniques such as MIG, TIG, and stick welding to join steel members.

- Operated cranes and rigging equipment to safely lift and position heavy steel components.

- Inspected steel structures and components for quality and safety compliance.

Accomplishments

- Successfully planned and executed the steel framing for a 20story office building, ensuring structural integrity and adherence to building codes.

- Utilized advanced surveying techniques to precisely align steel beams, reducing project delays and minimizing rework.

- Developed innovative solutions for complex steel connections, improving safety and optimizing load distribution.

- Implemented a lean manufacturing process to streamline material handling and assembly, reducing waste and increasing efficiency.

- Consistently exceeded quality standards, with all steel structures passing rigorous inspections on the first attempt.

Certificates

- OSHA 30-Hour Construction Safety Outreach Training

- Certified Welder (AWS)

- National Association of Tower Erectors (NATE) Fall Protection Certification

- Hoisting and Rigging Safety Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Hanger

- Highlight your welding certifications and experience with various welding techniques.

- Showcase your knowledge of OSHA safety regulations and commitment to fall protection.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job application, emphasizing the skills and experience most relevant to the specific project requirements.

- Include a portfolio or examples of your work to demonstrate your technical abilities.

Essential Experience Highlights for a Strong Steel Hanger Resume

- Fabricated and assembled structural steel components based on blueprints and specifications.

- Utilized welding techniques (MIG, TIG, stick) to join steel members.

- Operated cranes and rigging equipment to safely lift and position heavy steel components.

- Inspected steel structures and components for quality and safety compliance.

- Collaborated with engineers and supervisors to resolve technical issues and ensure project accuracy.

- Installed and maintained steel framing systems, such as beams, columns, and joists.

- Assembled and erected preengineered metal buildings following manufacturers’ guidelines.

Frequently Asked Questions (FAQ’s) For Steel Hanger

What is the primary role of a Steel Hanger?

A Steel Hanger is responsible for fabricating, assembling, and installing structural steel components according to blueprints and specifications, ensuring quality and safety compliance throughout the project.

What are the essential skills required for a Steel Hanger?

Essential skills include proficiency in welding techniques (MIG, TIG, stick), crane operations, rigging, fall protection, and knowledge of OSHA safety regulations.

What industries employ Steel Hangers?

Steel Hangers are employed in various industries, including construction, manufacturing, and infrastructure development.

What are the career prospects for Steel Hangers?

Experienced Steel Hangers can advance to supervisory roles, such as Foreman or Superintendent, or specialize in areas such as welding inspection or project management.

What are the safety considerations for Steel Hangers?

Steel Hangers must adhere to OSHA safety regulations, including proper use of fall protection equipment, working at heights, and handling heavy materials.

What training or certifications are beneficial for Steel Hangers?

Industry-recognized welding certifications, such as AWS certifications, and safety certifications, such as OSHA 30-Hour or 10-Hour Construction Safety Training, are highly valued.

Is physical strength important for Steel Hangers?

Yes, Steel Hangers must possess physical strength to lift and maneuver heavy steel components.